Composite three-layer net cloth and manufacturing method thereof

A three-layer mesh and surface layer technology, applied in rayon manufacturing, melt spinning, textiles and papermaking, etc., can solve the problems of difficulty in cleaning and application limitations of three-layer mesh, and achieve excellent washability, excellent Deodorant properties, the effect of activating human immune cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

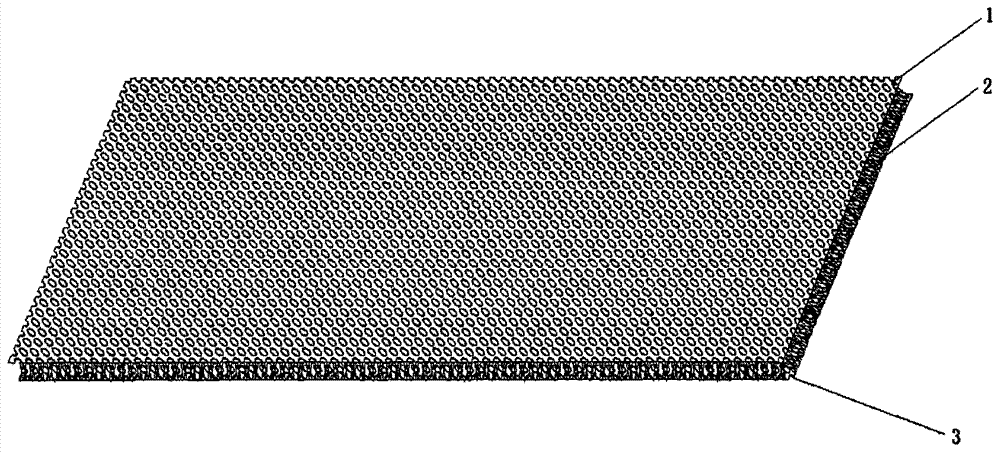

[0058] A composite three-layer mesh fabric, composed of a surface layer 1, a bottom layer 3 and a support layer 2 connected between the two; the surface layer, the bottom layer and the polyester monofilament support layer are woven into a three-dimensional three-layer mesh by warp knitting cloth.

[0059] The surface layer is composed of multifunctional polyester multifilament yarns and multifunctional polyester monofilaments woven into X-cross structure yarns.

[0060] The bottom layer is composed of multifunctional polyester multifilament yarns.

[0061] The supporting layer is composed of multifunctional polyester monofilament yarns.

[0062] The specification of the multifunctional polyester multifilament of the surface layer is 100D, 960mm / Rack

[0063] The specifications of the bottom layer multifunctional polyester multifilament are 75D, 1780mm / Rack.

[0064] The denier of the multifunctional polyester monofilament is 50 denier.

[0065] A method for preparing multifunctional poly...

Embodiment 2

[0085] A composite three-layer mesh fabric is composed of a surface layer, a bottom layer and a support layer connected between the two; the surface layer, the bottom layer and the polyester monofilament support layer are woven into a three-dimensional three-layer mesh cloth by warp knitting.

[0086] The surface layer is composed of multifunctional polyester multifilament yarns and multifunctional polyester monofilaments woven into X-cross structure yarns.

[0087] The bottom layer is composed of multifunctional polyester multifilament yarns.

[0088] The supporting layer is composed of multifunctional polyester monofilament yarns.

[0089] The specification of the multifunctional polyester multifilament of the surface layer is 100D, 960mm / Rack

[0090] The specifications of the bottom layer multifunctional polyester multifilament are 75D, 1780mm / Rack.

[0091] The denier of the multifunctional polyester monofilament is 75 denier.

[0092] A method for preparing multifunctional polyester...

Embodiment 3

[0110] A composite three-layer mesh fabric is composed of a surface layer, a bottom layer and a support layer connected between the two; the surface layer, the bottom layer and the polyester monofilament support layer are woven into a three-dimensional three-layer mesh cloth by warp knitting.

[0111] The surface layer is composed of multifunctional polyester multifilament yarns and multifunctional polyester monofilaments woven into X-cross structure yarns.

[0112] The bottom layer is composed of multifunctional polyester multifilament yarns.

[0113] The supporting layer is composed of multifunctional polyester monofilament yarns.

[0114] The specification of the multifunctional polyester multifilament of the surface layer is 100D, 960mm / Rack

[0115] The specifications of the bottom layer multifunctional polyester multifilament are 75D, 1780mm / Rack.

[0116] The denier of the multifunctional polyester monofilament is 150 denier.

[0117] A method for preparing multifunctional polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com