Vacuum centrifugal static spinning device

A technology of electrospinning and vacuum centrifugation, applied in electrospinning, textile and papermaking, filament/thread forming, etc., can solve the problems of environmental pollution, thick fiber, low spinning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

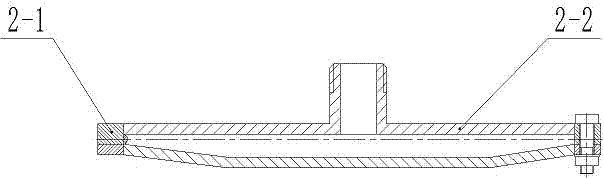

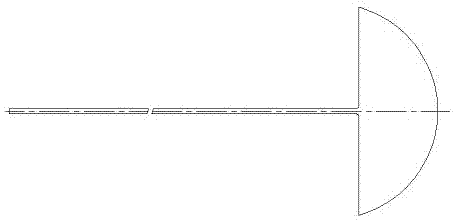

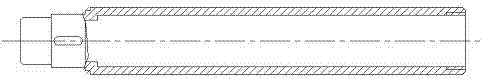

[0011] The vacuum centrifugal electrospinning device proposed by the present invention mainly includes eight devices of transmission, feeding, heating, sealing, spinning, collecting, temperature control and box. Firstly, the spinning device (2) is connected to the high voltage positive electrode, and the insulating collecting plate (19) is connected to the high voltage negative electrode, so that a stable electric field is formed between the spinning device and the collecting device. Determine the required spinneret diameter, use the plugging needle ( figure 2 ) to block unneeded spinnerets. Connect to the power supply, turn on the infrared thermometer (18), close the door of the vacuum box, and lock the locking buckle (1-1); the gas inside the vacuum box (1) is drawn out from the exhaust port (1-2) to ensure the vacuum Spend. When the pressure indication is stable, start the servo motor (4) to drive a pair of gears to move, the large and small gears (5, 13) drive the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com