Method for improving structure homogeneity and performance of large-section nodular cast iron

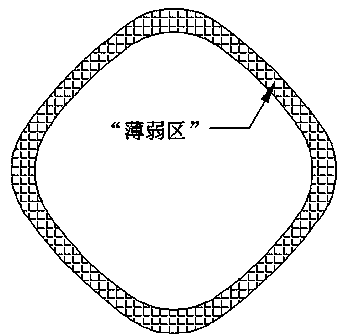

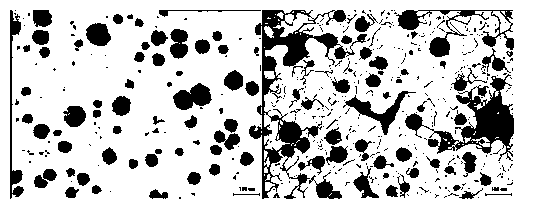

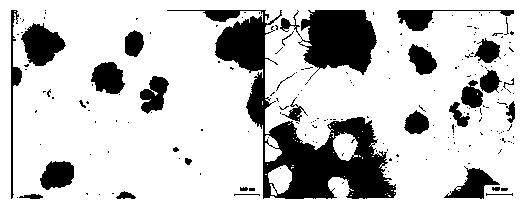

A technology for ductile cast iron with uniform structure, which is applied in the field of structure uniformity and performance of ferrite-based ductile iron castings for low-temperature and high-toughness wind power. It can solve the problems of limited inoculation effect, increase the number of graphite balls per unit area, and improve the structure Uniformity, improvement of structure, and improvement of graphite grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for improving microstructure uniformity and performance of large-section ductile iron, involving large-section ductile iron, the components of which are: C content 3.80%, Si content 2.0%, Mn content 0.126%, P The content is 0.022%, the S content is 0.017%, the Sb content is 50ppm, and the rest is Fe and unavoidable trace elements;

[0044] The method for improving structure uniformity and performance of large-section ductile iron comprises the following steps:

[0045] (1) Melting

[0046] A. Select the charge, which includes pig iron (30%), scrap steel (30%), and returned charge (40%);

[0047]B. Add a pretreatment agent accounting for 0.15% of the weight of molten iron to be released, and add it together with the charge;

[0048] C. After the furnace material is melted, remove the slag and take the sample in front of the furnace, detect the content of C, Si, Mn, P, S, adjust C and Si and desulfurize. The final composition in the furnace is: C: 3.80%, Si: 1...

Embodiment 2

[0068] A method for improving the structure uniformity and performance of large-section ductile iron, involving large-section ductile iron, the components of which are: C content 3.83%, Si content 2.09%, Mn content 0.127%, P The content is 0.021%, the S content is 0.018%, the Sb content is 80ppm, and the rest is Fe and unavoidable trace elements;

[0069] The method for improving structure uniformity and performance of large-section ductile iron comprises the following steps:

[0070] (1) Melting

[0071] A. Select the charge, which includes pig iron (30%), scrap steel (25%), and returned charge (45%);

[0072] B. Add a pretreatment agent accounting for 0.17% of the weight of molten iron to be released, and add it together with the charge;

[0073] C. After the furnace material is melted, remove the slag and take a sample before the furnace, detect the content of C, Si, Mn, P, and S, adjust C and Si and desulfurize. The final composition in the furnace is: C: 3.83%, Si: 1.1...

Embodiment 3

[0093] A method for improving microstructure uniformity and performance of large-section ductile iron, involving large-section ductile iron, the components of which are as follows in terms of mass percentage: C content is 3.85%, Si content is 2.2%, Mn content is 0.133%, P The content is 0.021%, the S content is 0.014%, the Sb content is 100ppm, and the rest is Fe and unavoidable trace elements;

[0094] The method for improving structure uniformity and performance of large-section ductile iron comprises the following steps:

[0095] (1) Melting

[0096] A. Select the furnace charge, which includes pig iron (35%), scrap steel (30%), and recycled charge (35%);

[0097] B. Add a pretreatment agent accounting for 0.2% of the weight of molten iron to be released, and add it together with the charge;

[0098] C. After the furnace material is melted, remove the slag and take the sample in front of the furnace, detect the content of C, Si, Mn, P, S, adjust C and Si and desulfurize. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com