Graphene-containing silicon rubber heat-conducting composite material and preparation method thereof

A thermally conductive composite material and graphene technology, applied in the field of thermally conductive polymer composite materials, can solve problems such as the deterioration of mechanical properties of silicone rubber, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned graphene / inorganic heat-conducting filler composite heat-conducting silicone rubber material is as follows: firstly, on a double-roll mill, inorganic heat-conducting fillers, graphene, cross-linking agents and other additives are mixed evenly with silicone rubber to obtain heat-conducting silicone rubber pre-mixed. Polymer. Then put the above-mentioned prepolymer on a flat vulcanizing machine for hot pressing to obtain a section of vulcanized heat-conducting silicone rubber. Then put the above-mentioned one-stage vulcanization product into an oven for two-stage vulcanization, and finally obtain the composite heat-conducting silicone rubber. The method specifically includes the following steps:

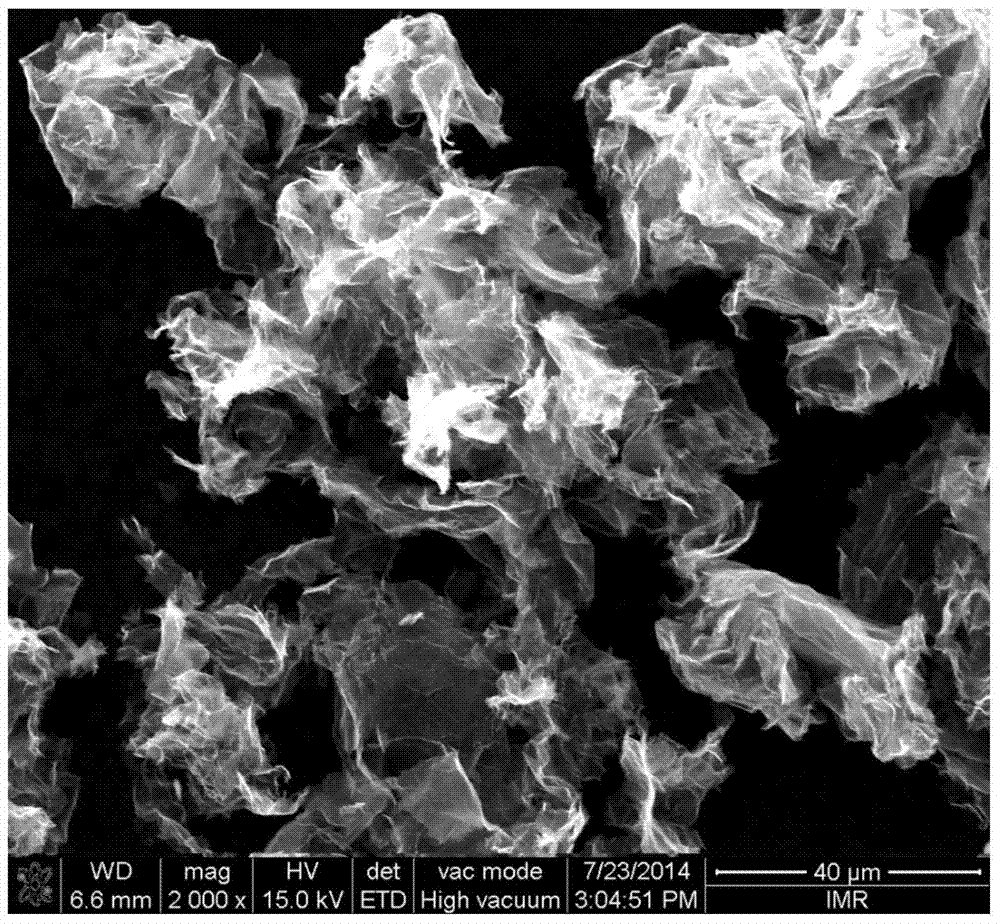

[0043] (1) Preparation of surfactant-treated graphene: first surfactant is added to deionized water, surfactant by weight: water=0.1~3:100, to obtain an aqueous solution containing surfactant; then under stirring condition Add grap...

Embodiment 1

[0051] In this embodiment, a graphene / aluminum oxide composite thermally conductive silicone rubber composite material is prepared, and the content of graphene in the composite thermally conductive film material is 5.0 wt%.

[0052] First, add 10 grams of methyl vinyl silicone rubber to the double-roller mill and mix evenly, then add 3 grams of fumed silica, 45 grams of aluminum oxide treated with silane coupling agent KH-550 and silane 3.0 grams of graphene treated with coupling agent KH-550, 0.20 grams of cross-linking agent 2,5-dimethyl-2,5 di-tert-butylperoxyhexane (double 2,5), etc. are mixed until uniform to obtain thermal conductivity Silicone rubber prepolymer. The obtained heat-conducting silicone rubber prepolymer was placed on a flat vulcanizing machine and hot-pressed at 165° C. and 10 MPa for 10 minutes to obtain a stage of vulcanized heat-conducting silicone rubber. Then put the obtained one-stage vulcanized heat-conducting silicone rubber into an oven for two-s...

Embodiment 2

[0055] In this embodiment, a graphene / aluminum oxide composite thermally conductive silicone rubber composite material is prepared, and the content of graphene in the composite thermally conductive film material is 3.3 wt%. Other preparation methods are the same as in Embodiment 1, and the measured thermal conductivity of the composite thermally conductive silicone rubber is 2.28w / m·k (40°C).

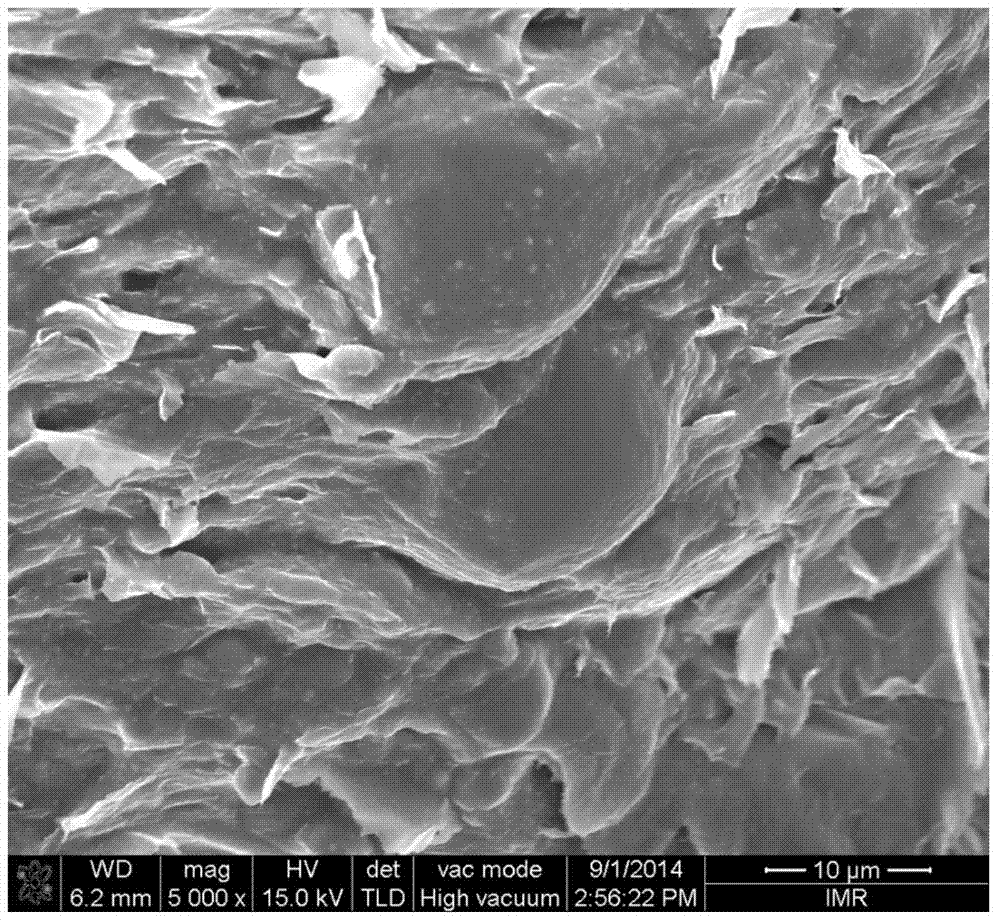

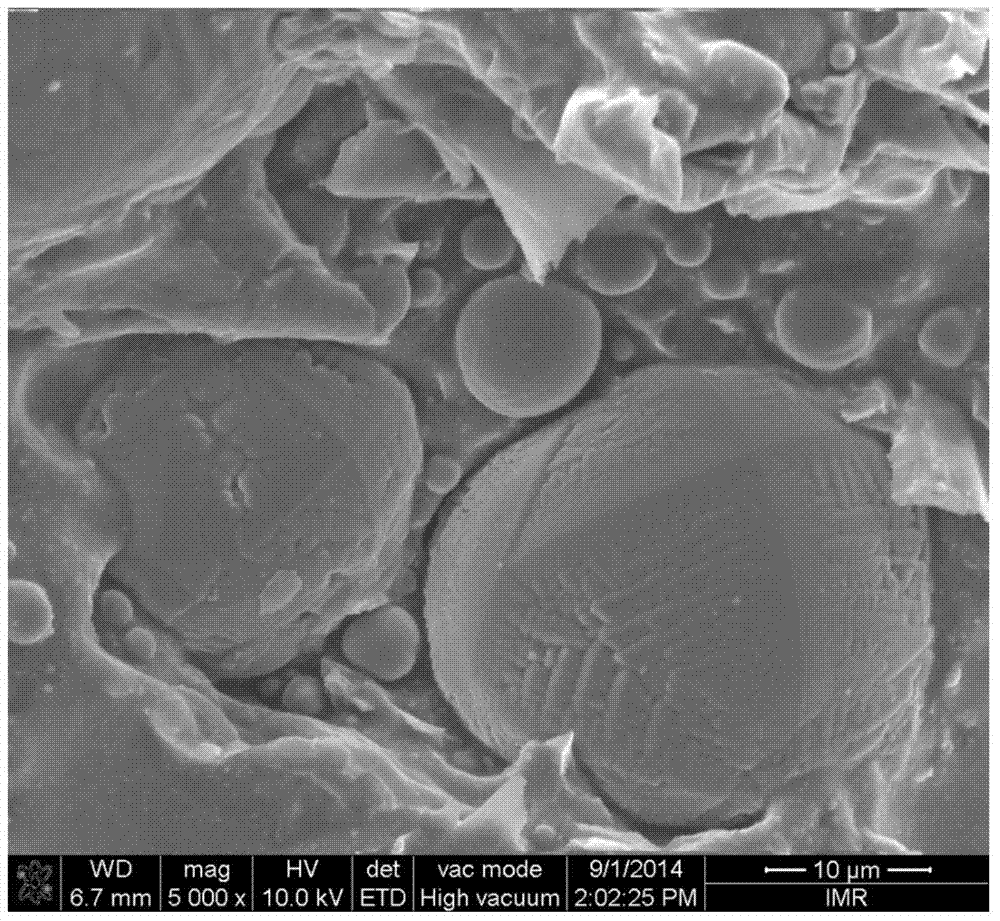

[0056] like image 3 As shown, it can be seen from the scanning electron microscope photo of the graphene / aluminum oxide composite thermally conductive silicone rubber material that graphene and aluminum oxide are evenly distributed in the silicone rubber and form a composite thermally conductive network.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com