A method and device for producing salt from seawater

A seawater and brine technology, which is applied in the fields of salt production and seawater desalination, can solve problems such as the bad influence of the surrounding environment of seawater and the imbalance of seawater ecological environment, and achieve the effect of realizing reuse and increasing the degree of brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

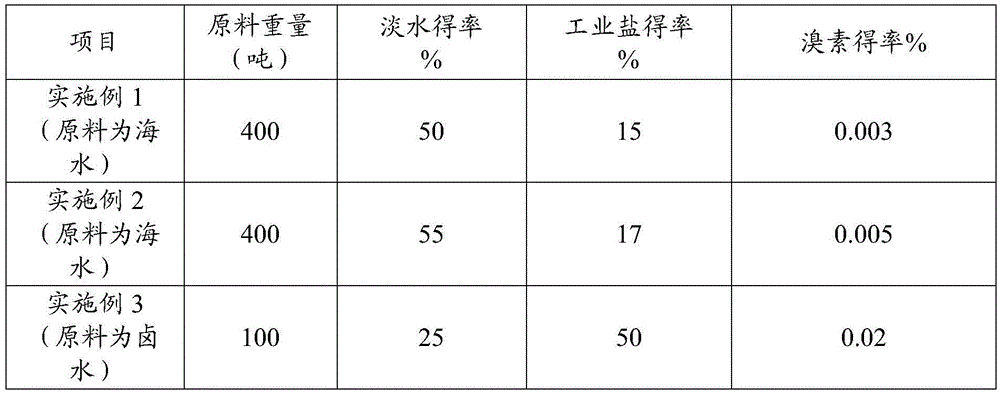

Embodiment 1

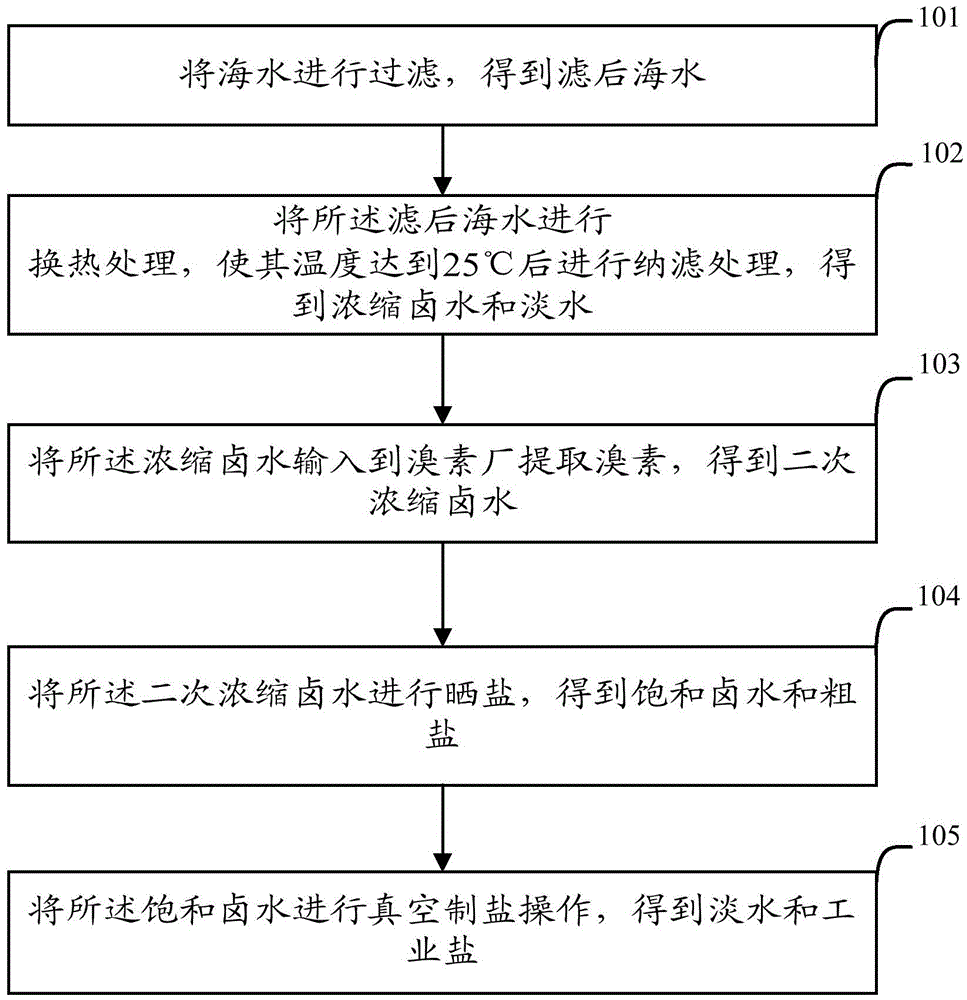

[0056] Please refer to figure 1 The method for producing salt from seawater provided by the embodiments of the present invention comprises the following steps:

[0057] Step 101: filtering seawater to obtain filtered seawater;

[0058] In this step, by filtering, the suspended solids contained in the seawater and the large particle size impurities (greater than 5 microns) are removed, thereby ensuring the cleanliness of the filtered seawater, and further overcoming the problem of the seawater in the nanofiltration process. Potential danger of damage to the nanofiltration membrane caused by large particle size impurities.

[0059] Step 102: heat-exchanging the filtered seawater until its temperature reaches 25°C, and then performing nanofiltration treatment to obtain concentrated brine and fresh water;

[0060] Generally speaking, in the process of nanofiltration treatment, when the temperature of the filtered seawater is 20-22°C, the nanofiltration effect is the best; moreov...

Embodiment 2

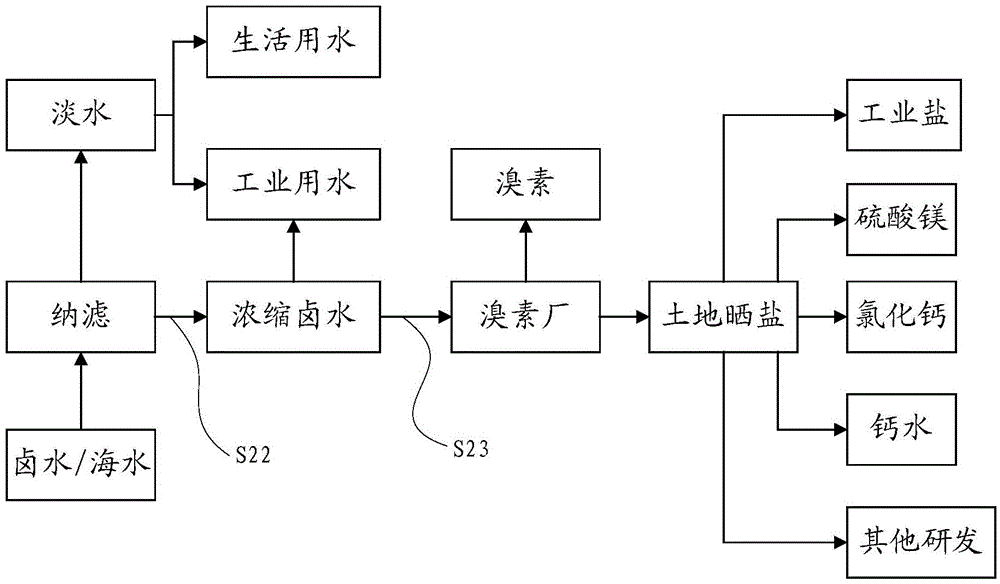

[0071] The method for producing salt from seawater provided by the embodiment of the present invention includes the following steps, please refer to figure 2 :

[0072] S21: After adding bactericide and flocculant to seawater, perform quartz sand filtration, activated carbon filtration and security filtration to obtain filtered seawater;

[0073] A fungicide is added to the seawater to kill harmful microorganisms in the seawater and ensure the safety of the subsequent fresh water and salt production process. The flocculants added mainly include inorganic flocculants, organic flocculants, microbial flocculants and composite flocculants. Among them, among the inorganic flocculants, aluminum salts and iron salts are the most widely used; while among the organic flocculants, poly(phenylene amide) is the most commonly used. The turbidity and chemical oxygen demand are reduced, and the suspended solids can be filtered out after flocculation. In this application, preferably, the ...

Embodiment 3

[0088] Example 3

[0089] The device for realizing the method of using seawater to produce salt provided by the embodiment of the present invention includes a primary filter device, a ground source heat pump, a nanofiltration device, bromine extraction equipment, and an MVR evaporator;

[0090] Among them, the primary filtering device: used to filter seawater to obtain filtered seawater; ground source heat pump: used to exchange heat for the filtered seawater and make the temperature reach 20-35°C; nanofiltration device: used for The filtered seawater after heat exchange is subjected to nanofiltration treatment, and concentrated brine and fresh water are obtained; bromine extraction equipment: used to separate bromine in concentrated brine, and to obtain secondary concentrated brine; MVR evaporator is used to extract saturated brine The fresh water in the brine is separated, and fresh water and industrial salt are obtained.

[0091] Preferably, in order to make the filtering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com