Multifunctional manipulator

A technology of multi-functional manipulators and slewing mechanisms, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

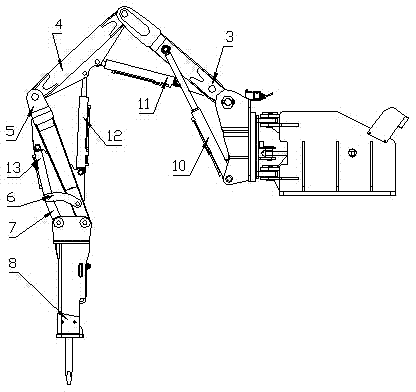

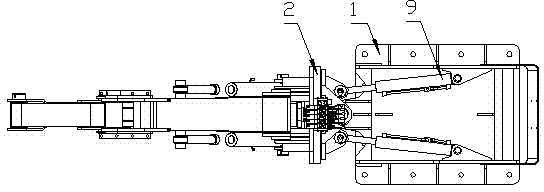

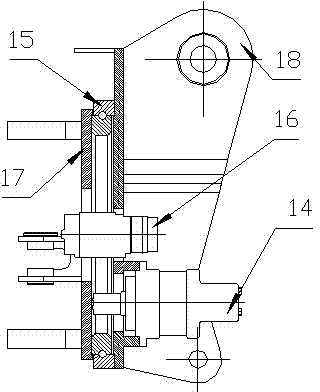

[0010] It can be seen from the drawings that a multifunctional manipulator of the present invention includes a swing mechanism and a working arm mechanism; the swing mechanism includes a base 1, a revolving mechanism 2, and two swing cylinders 9, and the working arm mechanism includes an arm 3, two arms 4, Three-arm 5, rocker 6, connecting rod 7, attachment 8, one-arm cylinder 10, two-arm cylinder 11, three-arm cylinder 12, rotary hammer cylinder 13; one end of the swing cylinder 9 is hinged on the base 1, the other end is hinged on On the slewing mechanism 2; one end of the arm 3 is hinged with the slewing mechanism 2, and the other end is hinged with the second arm 4; one end of the three arm 5 is hinged with the second arm 4, and the other end is hinged with the attachment 8; one end of the arm cylinder 10 is hinged with the slewing mechanism 2 The other end is hinged to the middle of the first arm 3; one end of the two-arm cylinder 11 is hinged to the middle of the first arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com