Winding and setting mechanism and timekeeper

A clockwork and barrel technology, applied in the field of clocks and watches, can solve the problems of inflexible operation, easy damage, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

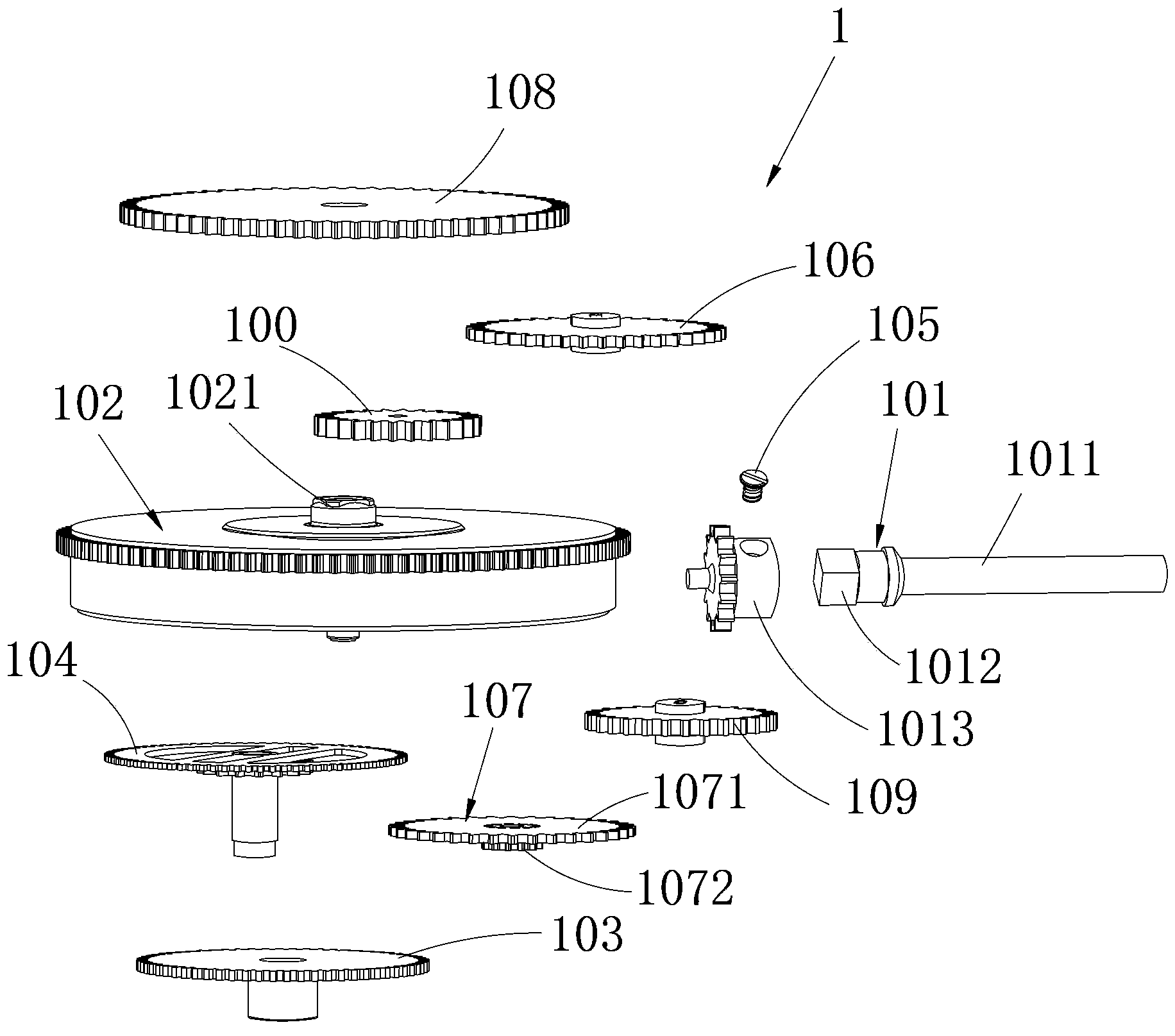

[0022] Such as Figure 1~4 Shown is a preferred embodiment provided by the present invention.

[0023] The winding needle setting mechanism 1 provided in this embodiment includes a rotatable stem 101, a barrel gear 102 with a mainspring inside, a minute gear 104, and an hour wheel 103 sleeved on the minute gear 104. The stem 101 One end is provided with a vertically arranged vertical gear 1013, the top of the vertical gear 1013 is provided with a first gear structure 106 that can be rotated by the vertical gear 1013 in the forward direction, and the bottom is provided with a gear structure 106 that can be rotated by the vertical gear 1013 in the reverse direction. The second gear structure 109 .

[0024] The first intermediate gear train is meshed between the first gear structure 106 above the vertical gear 1013 and the barrel gear 102. Only when the vertical gear 1013 rotates forward, the first intermediate gear train can be driven to rotate, that is: when When the first ge...

Embodiment 2

[0039] Such as Figure 5 Shown is another preferred embodiment provided by the present invention.

[0040] The difference between this embodiment and Embodiment 1 is that the first gear structure is the first reversing gear 111, and the second gear structure is the second reversing gear 112. The first reversing gear 111 includes the vertical gear 1013 and can The first lower switching gear 1112 driven to rotate by the vertical gear 1013 and the first upper switching gear 1111 placed above the first lower switching gear 1112, and when the first lower switching gear 1112 rotates forward, It can drive the first reversing upper gear 1111 to rotate. On the contrary, when the first reversing lower gear 1112 rotates in the opposite direction, the first reversing upper gear 1111 will not rotate with the first reversing lower gear 1112, that is, the first reversing lower gear 1112 will not rotate. In the disengaged state; similarly, the second reversing gear 112 includes a second reve...

Embodiment 3

[0045] Such as Figure 6 Shown is another preferred embodiment provided by the present invention.

[0046] The difference between this embodiment and Embodiments 1 and 2 is that the above-mentioned first gear structure is the first sliding gear 106 in Embodiment 1, and correspondingly, the second gear structure is the second reversing gear in Embodiment 2 gear 112. In this way, when the vertical gear 1013 rotates forward, it can drive the first sliding gear 106 to rotate, and then drive the first intermediate gear train to rotate to realize the winding operation; Rotate to the gear 112, and then drive the second intermediate gear train to rotate, thereby realizing the needle setting operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com