Refractory brick processing machinery construction environment spray dust collector

A technology for processing machinery and construction environment, applied in stone processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of construction workers inhaling a large amount of dust, achieve good dust removal effect, convenient production and transportation, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

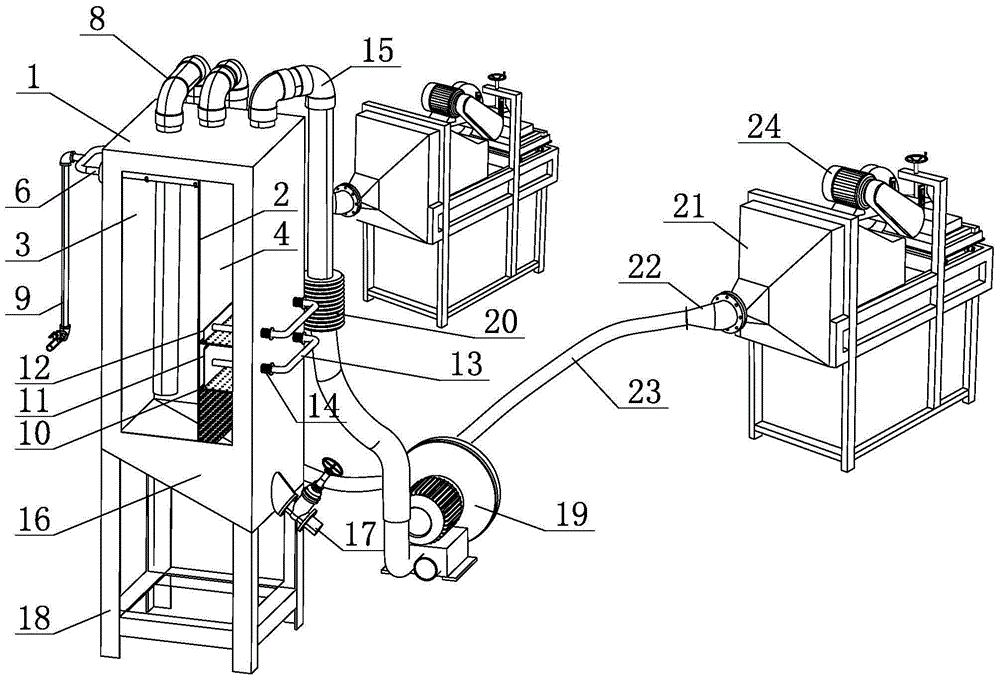

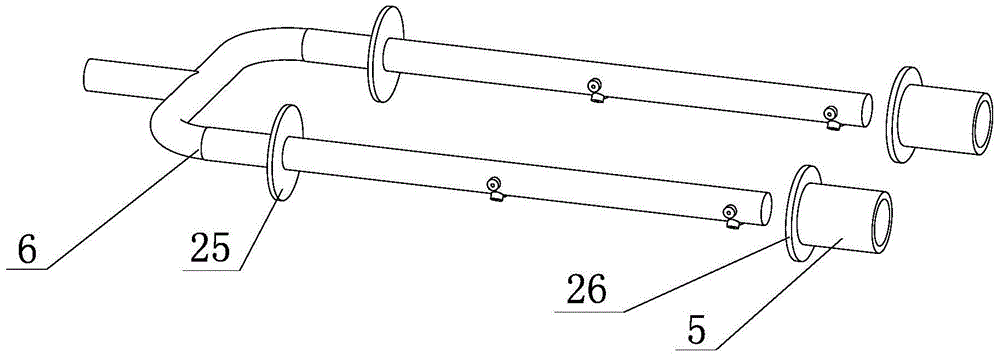

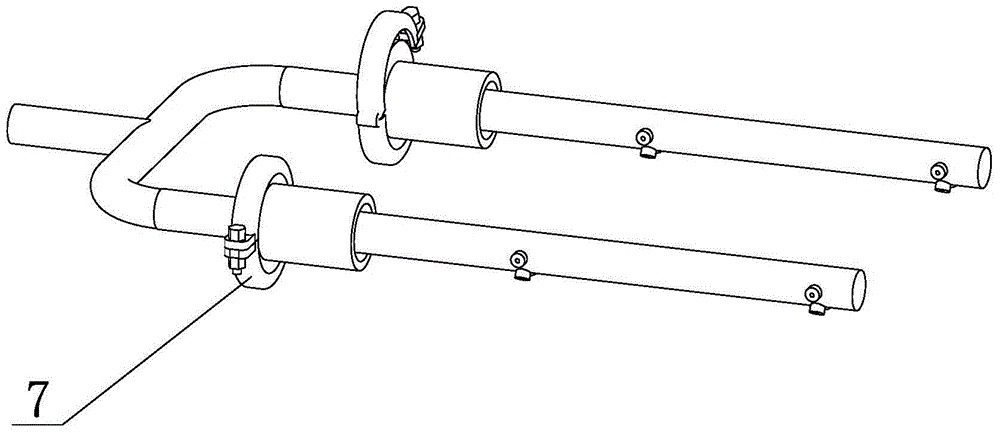

[0029] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0030] A spray dust collector for refractory brick processing machinery construction environment, characterized in that it includes a dust removal box, a bracket 18, an air pump 19, a dirty air pipe 8 and a clean air pipe 15, the dust removal box is installed on the bracket 18, and the dirty air pipe 8 Used to absorb dirty gas (such as used to connect the dust removal box and brick cutter 24), the air cleaning pipe 15 is used to connect the dust removal box and the air pump 19;

[0031] The dust removal box includes a box body 1. The lower surface of the box body 1 (cuboid or cylinder) is open, and a slag storage hopper 16 is sealed and connected to the opening (a closed space is formed between the two). The outlet of the bucket 16 is provided with a slag removal valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com