Numerical-control cutter measuring device of spiral bevel gear milling machine

A technology of spiral bevel gear and gear milling machine, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc. It can solve the problems of affecting the cutting precision, damaging the meter head, and assembly error of the tool spindle, so as to avoid damage Meter, accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

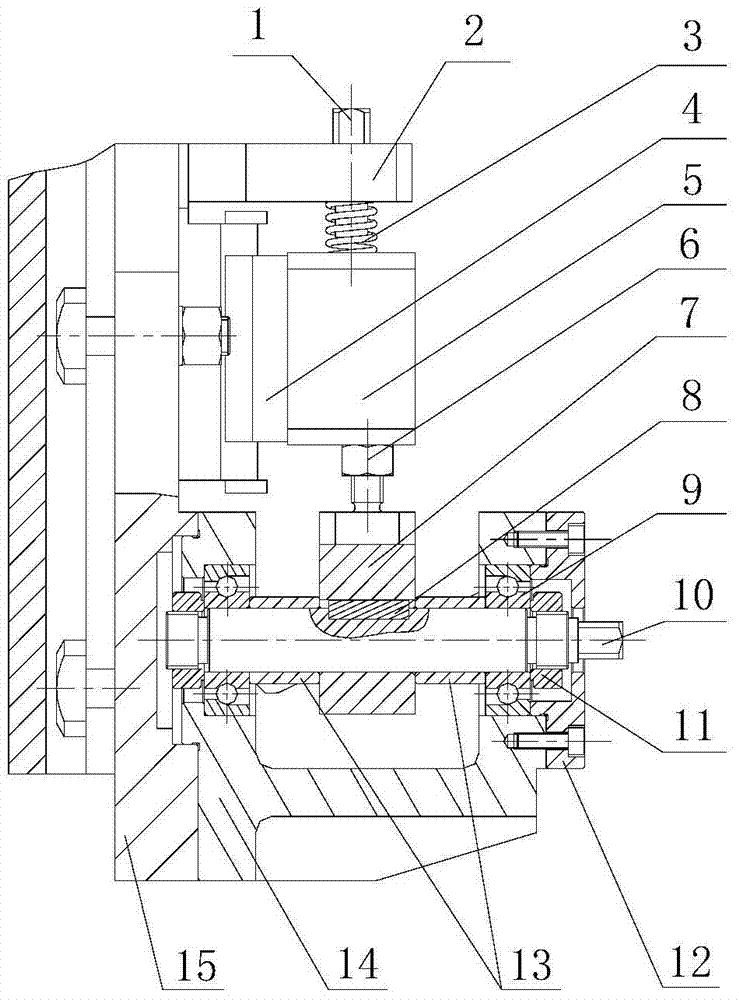

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

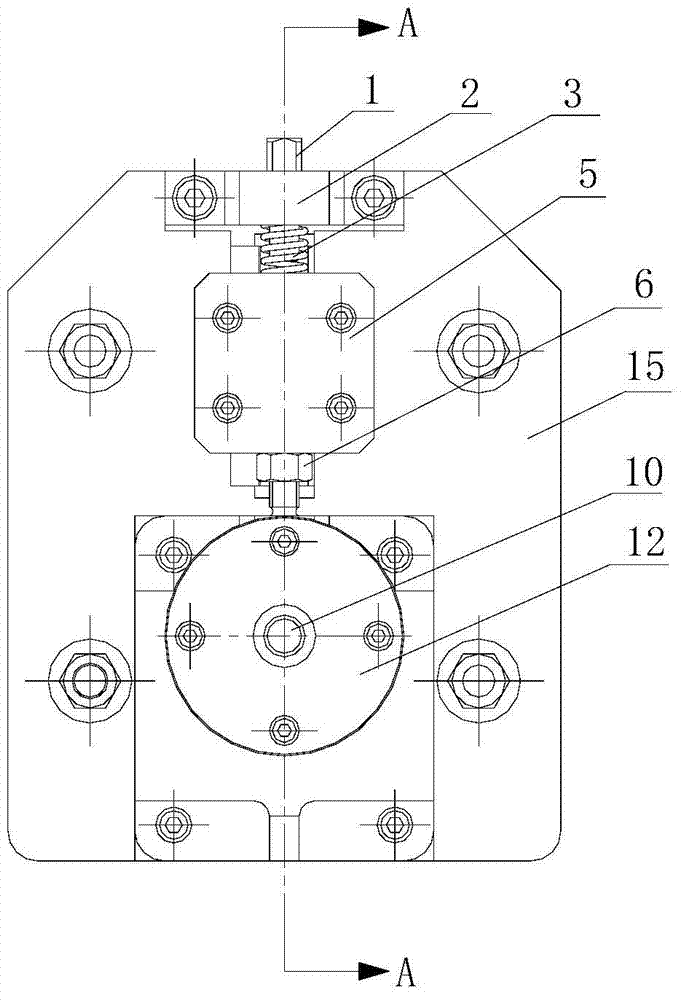

[0015] see figure 1 and figure 2 , the CNC spiral bevel gear milling machine tool measuring device, including a base plate 15 installed on the end cover of the cradle, a tailstock 2 and a guide rail 16 located below the tailstock are installed on the upper side of the base plate, and the guide rail is equipped with a Its guide rail slide block 4 that slides up and down, a bearing seat 14 is fixedly installed on the bottom side of the bottom plate, a rotating shaft 10 is housed in the described bearing seat, and a cam 7 is connected with a key 8 on the rotating shaft, and the cam and the top Rod 6 is connected, and described ejector rod is connected with table base 5 that is installed on the guide rail slider, and described table base withst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com