Processing equipment for forming and grooving of spectacle frame nose bridge

A technology for processing equipment and mirror frames, applied in metal processing, other manufacturing equipment/tools, frames, etc., can solve problems such as non-synchronization, eye damage, and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

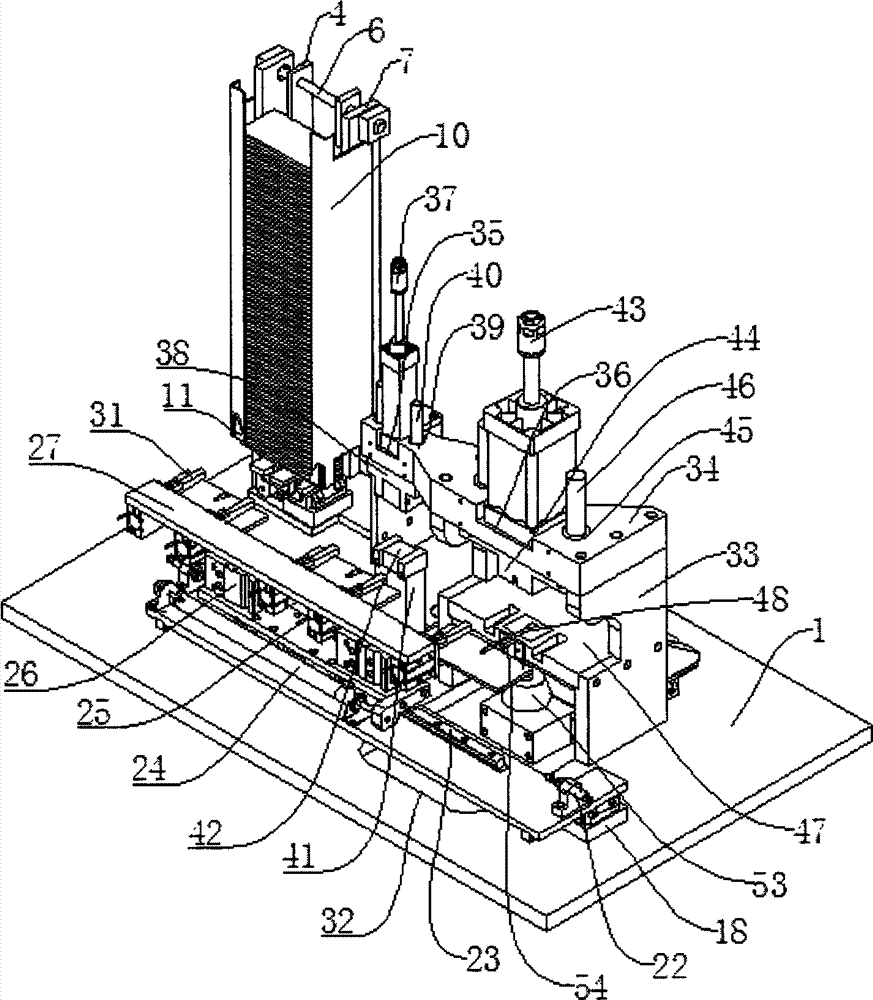

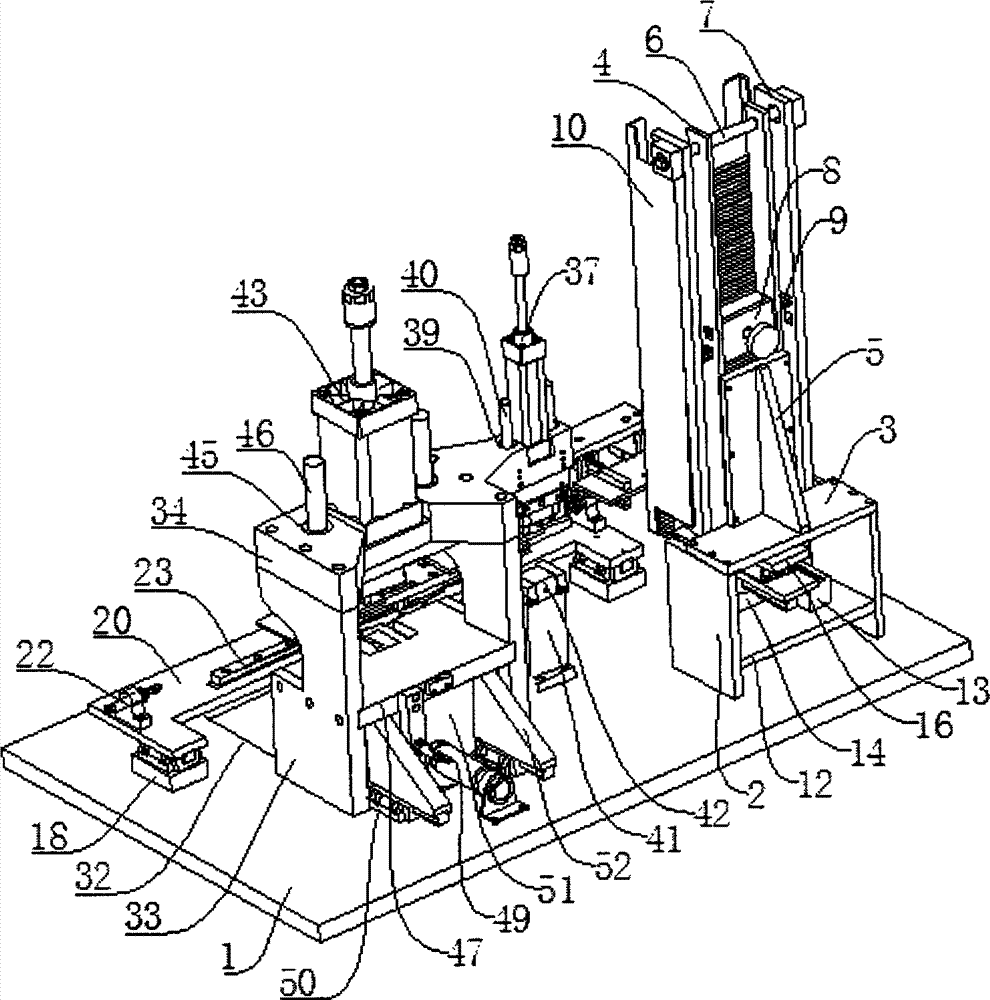

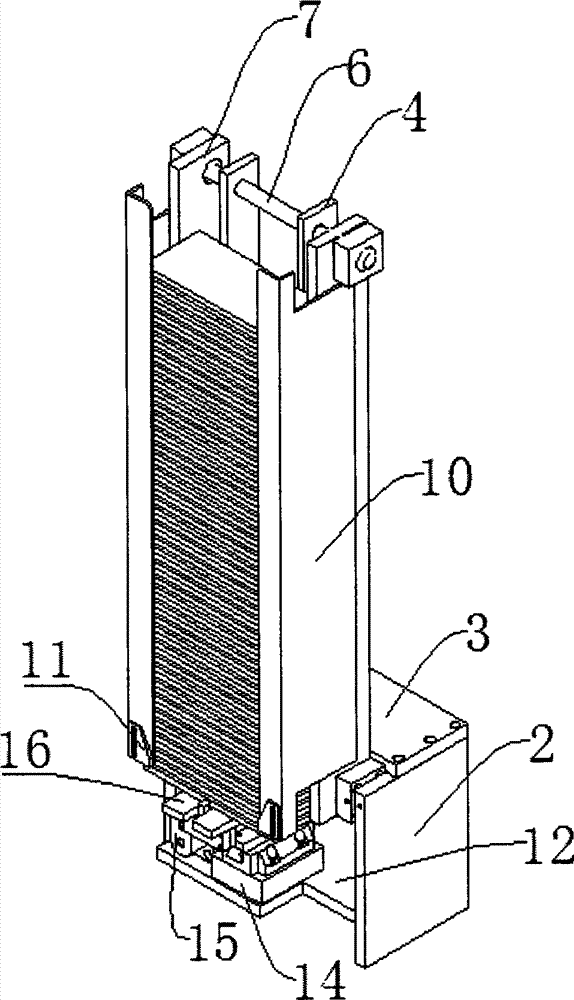

[0021] Such as Figure 1-12 The shown processing equipment for forming and grooving the bridge of the spectacle frame includes a bottom plate 1, a feeding mechanism and a clamping and conveying mechanism arranged on the bottom plate 1; the feeding mechanism includes a feeding side fixedly arranged on the bottom plate 1 Plate 2; the top of the feeding side plate 2 is fixedly provided with a feeding top plate 3; the front side of the feeding top plate 3 is provided with a feeding fixed plate 4; the feeding fixed plate 4 is fixedly connected with the feeding top plate 3 through a support frame 5; The upper and lower ends of the feeding top plate 3 are fixedly provided with feeding guide pillars 6; the outer side of the feeding fixed plate 4 is provided with a feeding movable plate 7; the feeding movable plate 7 is movably socketed with the feeding guide pillar 6; An adjustment box 8 is fixedly arranged between them; an adjustment rack 9 is fixedly arranged on the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com