A fully automatic wafer wax sticking machine

A waxing machine, fully automatic technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of low wafer processing efficiency, cumbersome work procedures, complex equipment structure, etc., and achieve improvement Product quality, improve product quality, and achieve the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

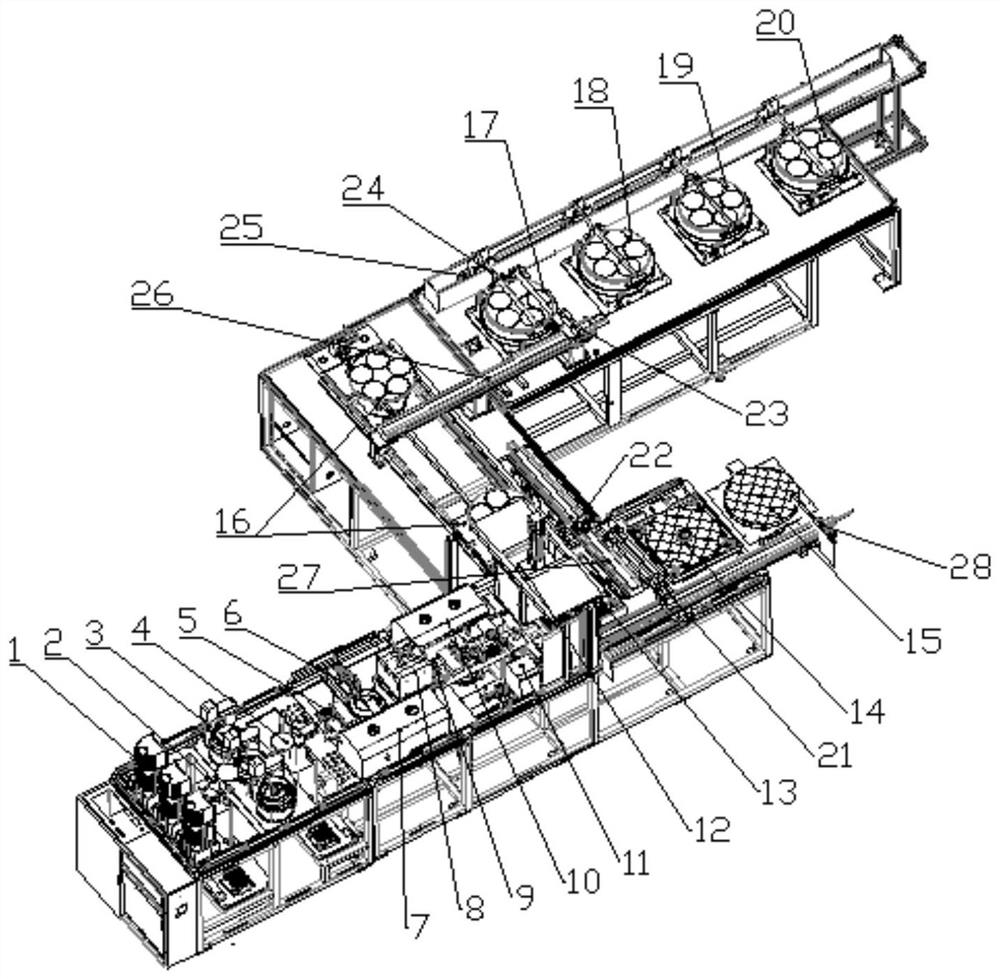

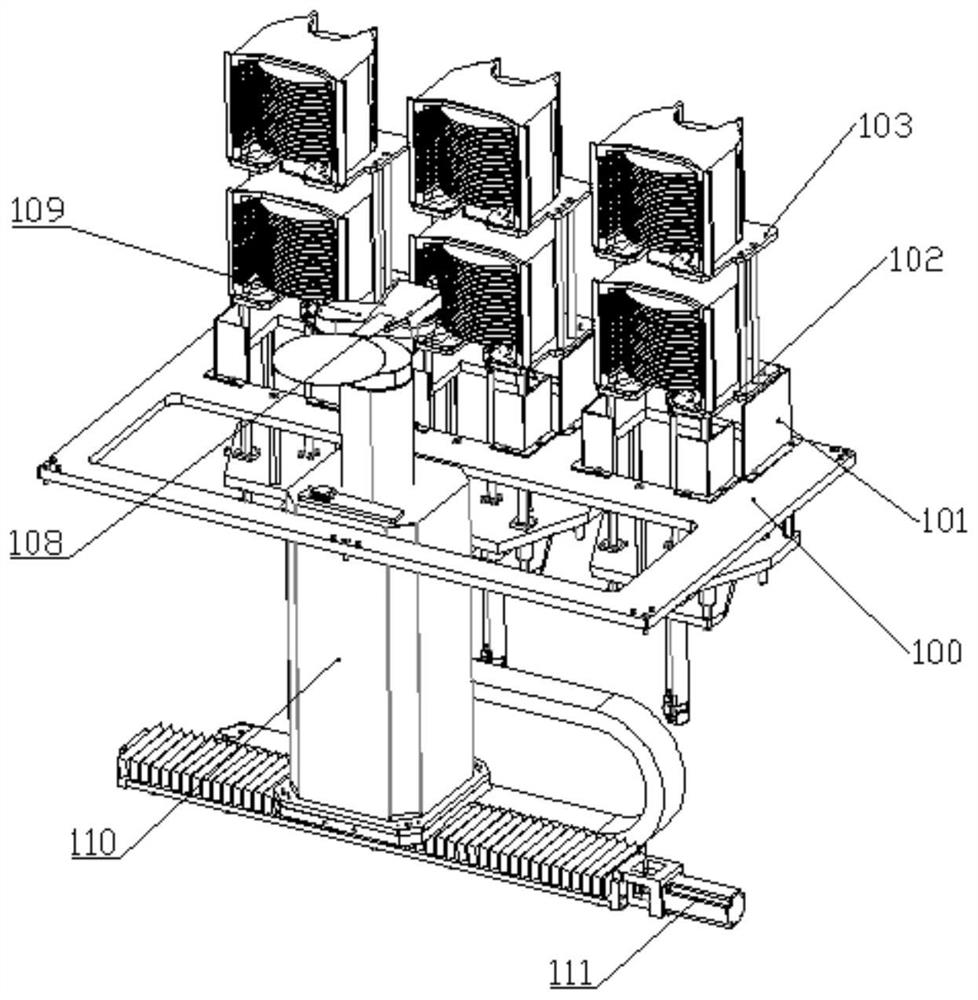

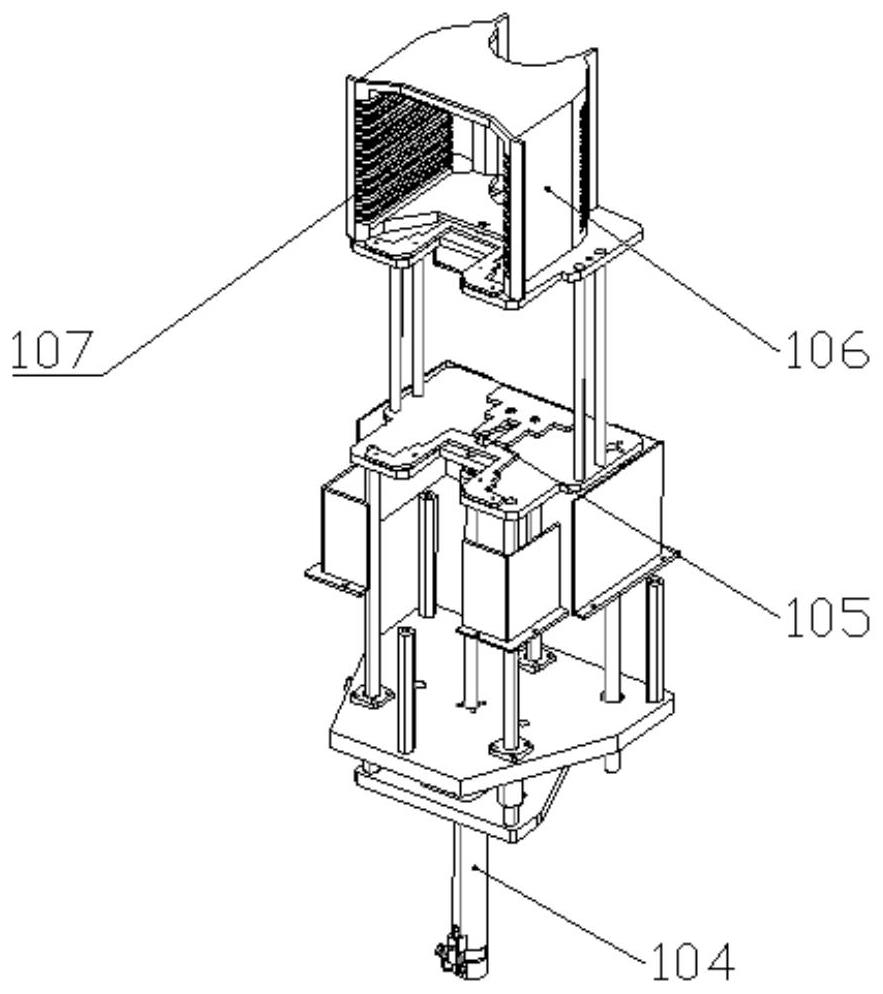

[0062] see Figure 1 to Figure 23 A fully automatic wafer wax sticking machine shown in the figure includes a wafer supply unit 1, a robot arm, a wafer cleaning unit 3, a centering unit, a wax dripping unit 6, a double-arm wafer transplanting unit, and a wafer turning unit 11. , wafer pressing unit 12, ceramic disc heating unit, turnover unit 16, cooling unit and carrier, the manipulator includes manipulator one 2 and manipulator two 4, and the centering unit includes centering unit one 5 and centering unit 29. The dual-arm wafer transplanting unit includes a dual-arm wafer transplanting unit 1 7 and a dual-arm wafer transplanting unit 2 10. The ceramic disc heating unit includes a ceramic disc low-temperature heating unit 13, a ceramic disc pre-heating unit Thermal unit 2 14 and ceramic disc preheating unit 1 15, the cooling unit includes cooling unit 1 17, cooling unit 2 18, cooling unit 3 19 and cooling unit 4 20, the wafer passes through wafer supply unit 1, robot 1 in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com