Mulberry leaf gamma-aminobutyric acid crude extract preparation method

A technology of aminobutyric acid and crude extract, which is applied in the field of food processing, can solve the problems of enhanced ability to absorb water, increase the viscosity of the extract, and low GABA concentration, so as to reduce the content of polysaccharides, maintain drug efficacy, and high concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

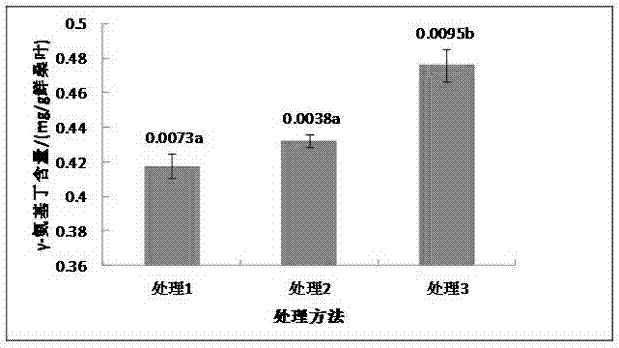

[0028] Example 1 Effects of Treatment Methods on the Content of γ-Aminobutyric Acid in Mulberry Leaves

[0029] (1) Three methods were used to process mulberry leaves. Treatment 1: Juicing without grinding; Treatment 2: Juicing directly after grinding; Treatment 3: Juicing after freezing for 24 hours after grinding. After the squeezed juice was centrifuged at 10,000 r / min, 1 mL of the sample liquid was taken to measure the GABA content, and the GABA content in each gram of fresh mulberry leaves was calculated, and statistical analysis was performed with SPSS 17.0. The results were as follows: figure 1 , Different letters in the figure indicate significant difference at 0.01 level.

[0030] The yield of gamma-aminobutyric acid directly squeezed without grinding was 0.4176 mg / g fresh leaves; the yield of directly squeezed juice after grinding was 0.4322 mg / g fresh leaves; the yield of squeezed juice after freezing for 24 hours after grinding was 0.4762 mg / g fresh leaves. ...

Embodiment 2

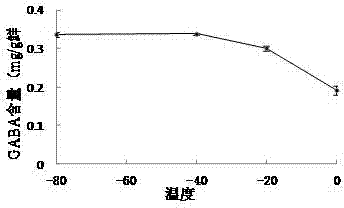

[0041] Example 2 Effect of freezing temperature on the extraction rate of γ-aminobutyric acid from mulberry leaves

[0042] Under the condition that the solid-liquid ratio is 1g mulberry leaves: 1mL distilled water and the freezing treatment time is 24 hours, the freezing temperatures are respectively designed as 0°C, -20°C, -40°C, -80°C, and the effect of freezing temperature on the GABA extraction amount of mulberry leaves is studied. effect, the result of which is figure 2 shown.

[0043] The results showed that the amount of GABA extracted from mulberry leaves increased with the decrease of temperature, the extraction amount was 0.19 mg / g fresh leaves at 0°C, 0.30 mg / g fresh leaves at -20°C, and 0.34 mg at -40°C / g fresh leaves, when the temperature is -80°C, the extraction amount is basically the same as that of -40°C. Although the extraction rate at -40°C is higher than that at -20°C, considering that refrigerators at -20°C are more commonly used and the price is lowe...

Embodiment 3

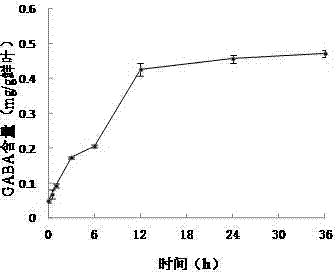

[0045] Example 3 Effect of freezing time on the extraction rate of γ-aminobutyric acid from mulberry leaves

[0046] In the case of a solid-liquid ratio of 1g mulberry leaves: 1mL distilled water and a freezing temperature of -20°C, the freezing time was designed to be 0.5, 1, 3, 6, 12, 24, and 36 hours, respectively, to study the effect of freezing time on the extraction of GABA from mulberry leaves. effect, see image 3 . The extraction amount of mulberry leaf GABA increased rapidly with the prolongation of the extraction time within 0-12h, and after 12h, although the extraction amount increased, but the increase rate was slow, so it is appropriate to determine the freezing treatment time as 12h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com