Direct drive LED lighting system controlled by integrated control circuit

An integrated control circuit and LED lighting technology, applied in the field of LED lighting, can solve the problems of low drive power supply efficiency of LED lamps, high drive current of high-power lighting systems, high cost of wires and cables, and achieve good anti-light flicker characteristics and low cost , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

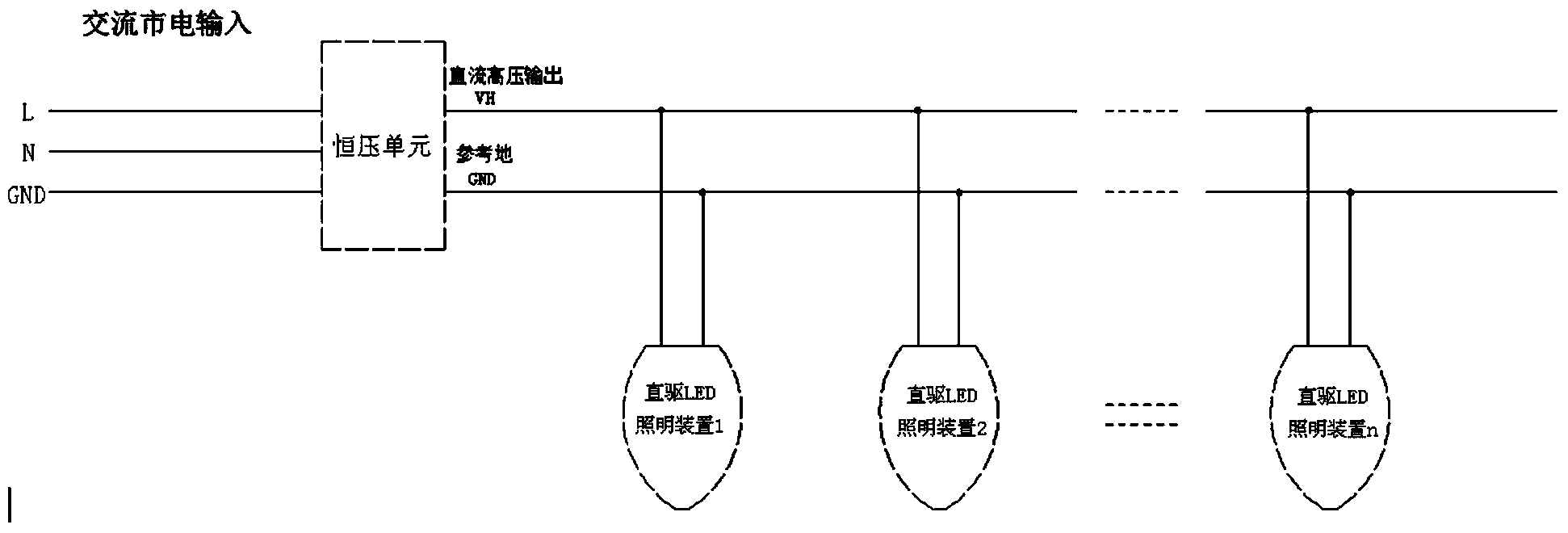

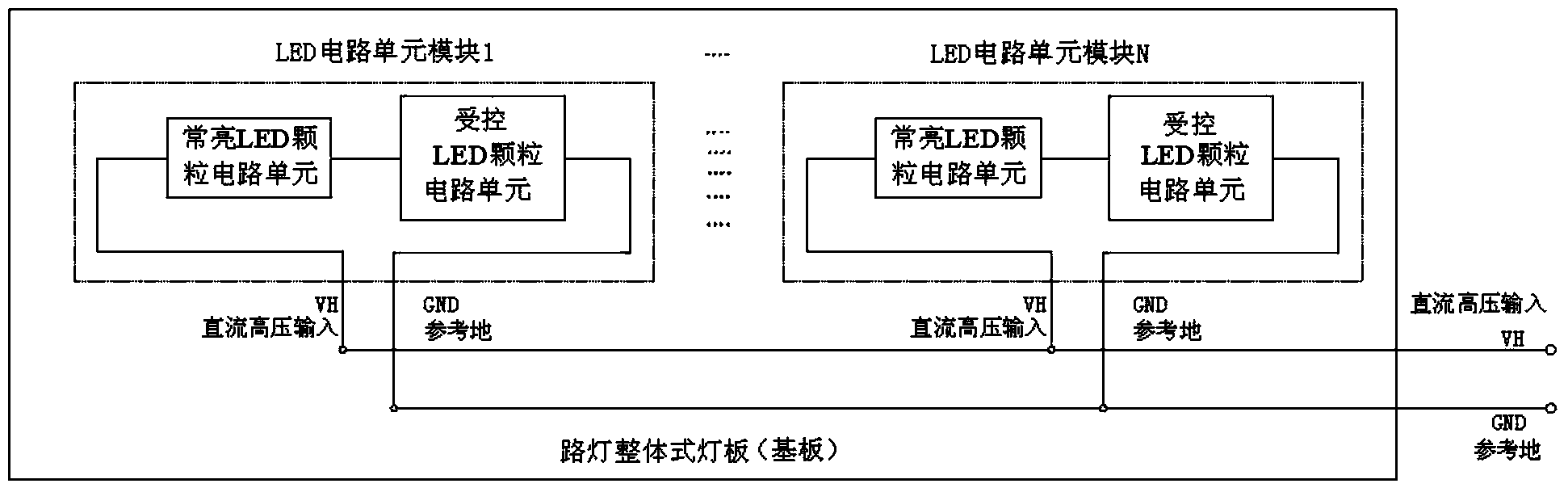

[0056] Please refer to figure 1 , figure 2 and Figure 4 , this embodiment has additional specific improvements on the basis of the above description of the basic solution.

[0057] In this embodiment, the direct-drive LED lighting device includes a substrate on which several LED circuits are arranged, and several LED circuits are connected in parallel between the high-voltage output terminal VH and the reference ground terminal GND. The full-page LED lighting device using a single substrate is beneficial to ensure the integrity and integrity of the lighting device.

Embodiment 2

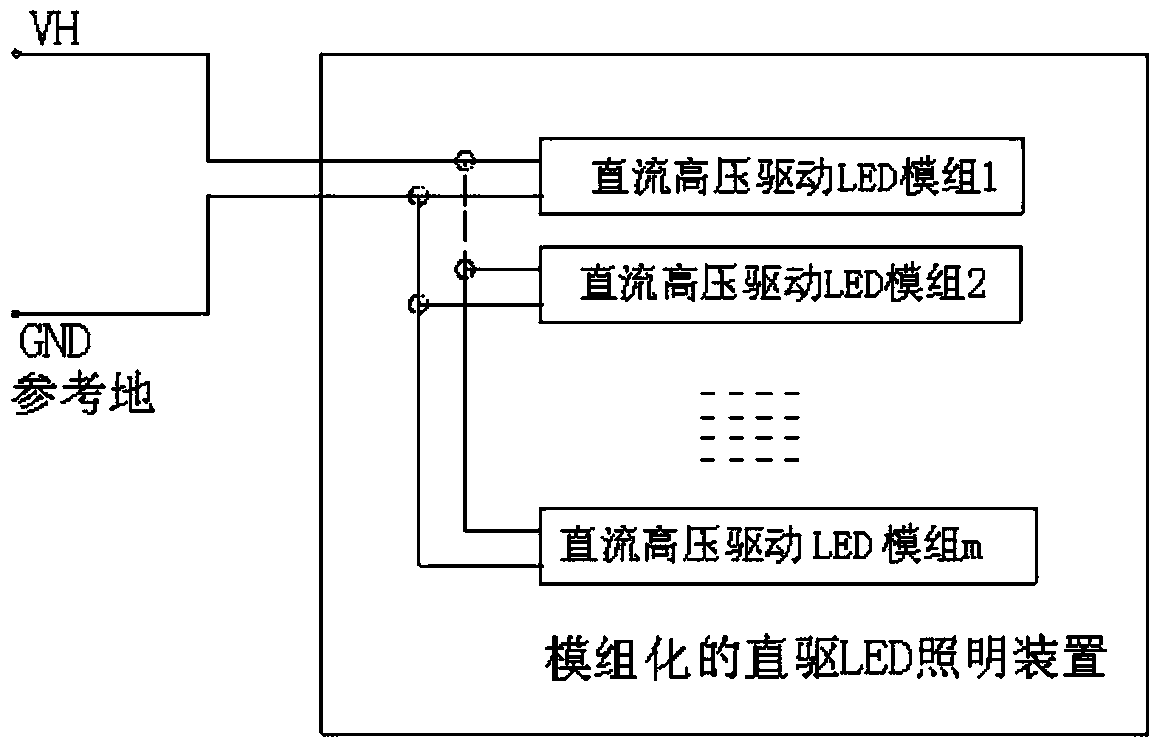

[0059] Please refer to figure 1 , image 3 and Figure 4 , this embodiment has additional specific improvements on the basis of the above description of the basic solution.

[0060] The direct-drive LED lighting device includes at least two DC high-voltage drive LED modules, each of the DC high-voltage drive LED modules includes one LED circuit, and each DC high-voltage drive LED module is correspondingly arranged in an independent on the substrate.

[0061] Several of the DC high voltage driving LED modules are connected in parallel between the high voltage output terminal VH and the reference ground terminal GND.

[0062] In this embodiment, the lighting device is configured as a module, and the lighting mode of the LED lighting system can be enriched by changing the combination of the modules. At the same time, the modularized lamp has certain advantages in heat dissipation performance, power, and assembly.

[0063] In summary, the present invention has the following be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com