Redundant half-tooth-winding magnetic flux switching motor

A magnetic flux switching motor, redundant technology, applied to synchronous motors with rotating armature and stationary magnets, magnetic circuit stationary components, magnetic circuit shape/style/structure, etc., can solve large radial magnetic pull, Problems such as large torque pulsation and noise, to achieve the effect of strong torque output capability, suppression of harmonic content, and optimization of sine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The redundant half-tooth-wound magnetic flux switching motor of the present invention will be described in detail below by taking the three-phase redundant half-tooth-wound magnetic flux switching motor as an example.

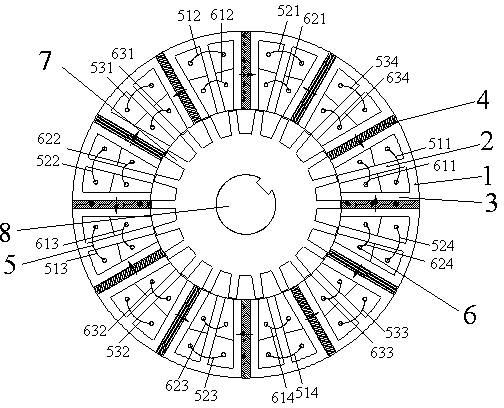

[0035] like figure 1As shown, the magnetic flux switching motor of the present invention includes a stator and a rotor, both of which are salient pole structures with an air gap between them; the stator is composed of a stator core 1 and a permanent magnet 4, so The stator core 1 is composed of a fault-tolerant tooth 2 and two magnetically conductive teeth 3, and the fault-tolerant tooth 2 is located between the two magnetically conductive teeth 3 to form an "E"-shaped core structure; Embed the permanent magnet 4 between them, the magnetization direction of the permanent magnet 4 is tangential, and the magnetization direction of the adjacent permanent magnet 4 is opposite; the armature coil 5 and the excitation coil 6 adopting a half-tooth winding struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com