External Cavity Coherent Vertical Cavity Surface Emitting Semiconductor Laser

A vertical cavity surface emission and laser technology, applied in the field of lasers, can solve the problems of complex structure and poor reliability of coherent lasers, and achieve the effect of high stability and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

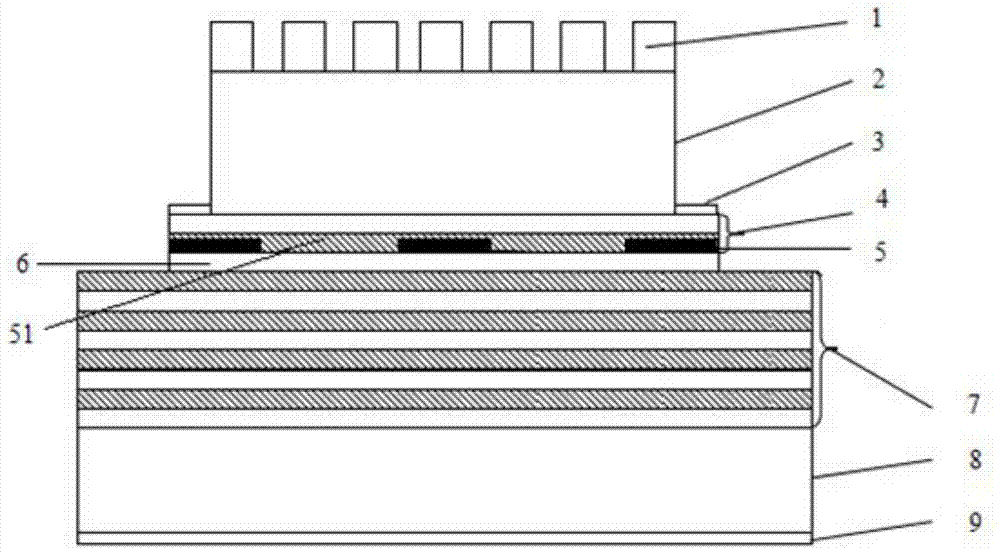

[0017] Such as figure 1 and figure 2 As shown, the external cavity coherent vertical cavity surface emitting semiconductor laser of the present invention includes a high-contrast grating, a P-side electrode 3 , a P-type DBR4 , an active region 6 , an N-type DBR7 , a substrate 8 and an N-side electrode 9 .

[0018] Wherein, the P-type DBR4, the active region 6, the N-type DBR7, the substrate 8 and the N-surface electrode 9 are closely arranged in sequence from top to bottom, and a buffer layer may also be provided between the N-type DBR7 and the substrate 8. The N-type DBR7 has a multi-layer structure, and the P-type DBR4 is composed of a layer of high-refractive-index material and a layer of low-refractive-index material closely arranged from top to bottom. The low-refractive index material layer is provided with multiple oxidation holes 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com