Support plate capable of improving performance of electric wetting displayer, manufacture technology thereof and electric wetting displayer

An electrowetting display and manufacturing process technology, applied in the direction of instruments, optical components, optics, etc., can solve problems such as insufficient surface area, oil ingress, and affecting device reliability, so as to improve device quality, avoid short circuits, and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

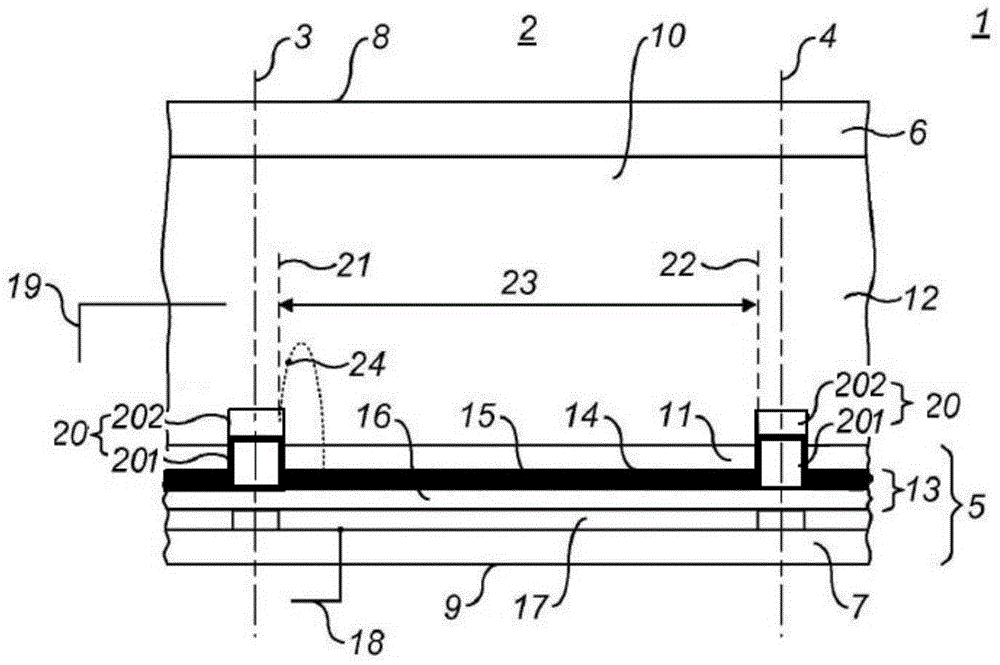

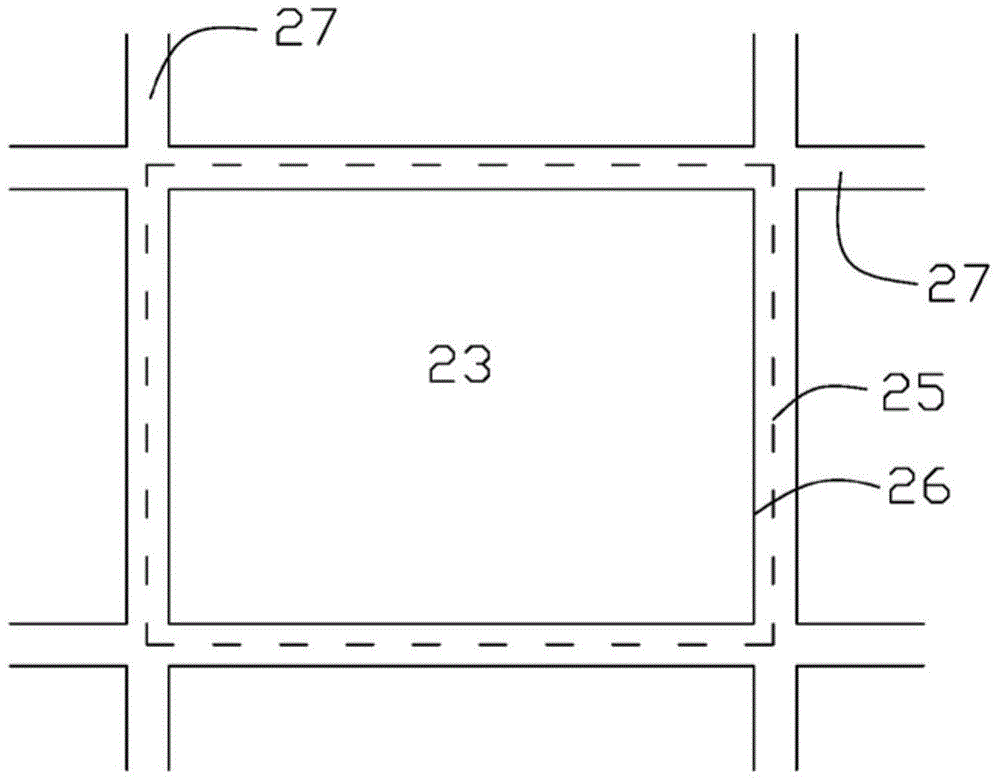

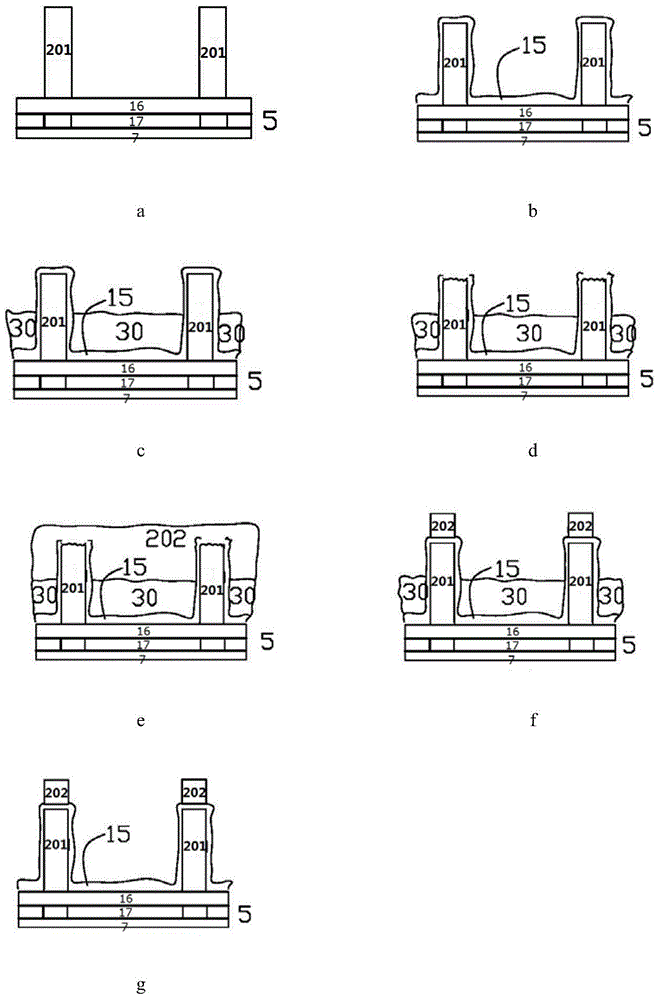

[0026] Such as Figure 1~Figure 2 as shown, figure 1 A partial cross-section of an electrowetting display is shown. The electrowetting display comprises a plurality of picture elements 2, one of which is shown in the figure. The lateral extent of the cell 2 is indicated by two dashed lines 3 and 4 in the figure. The pixel 2 includes a first support plate 5 and a second support plate 6 . These support plates 5 and 6 may be separate parts of each picture element 2 , but preferably these support plates 5 and 6 are shared by a plurality of picture elements 2 . The support plates 5 and 6 may comprise glass or polymer substrates 7 and 6 and may be rigid or flexible. The pixel wall 20 is arranged on the first support plate 5, more specifically, on the dielectric layer 16 or the first electrode 17, not on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com