Method for detecting cleanness of compressed air pipeline of offshore oil platform

A technology of compressed air tubes and offshore oil, which is applied in the direction of measuring devices, optical testing flaws/defects, particle suspension analysis, etc. It can solve undiscovered problems and achieve the effects of improving accuracy, reducing wear, and reducing sudden failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

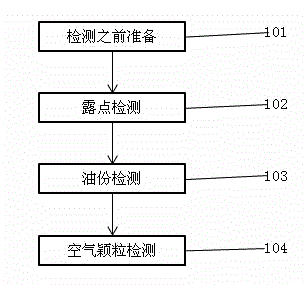

[0025] like figure 1 As shown, the present invention discloses a method for detecting the cleanliness of compressed air pipelines on offshore oil platforms, which is used to measure the moisture, oil and solid particle size levels contained in the compressed air of the instrument holder on offshore oil platforms;

[0026] Specific steps are as follows:

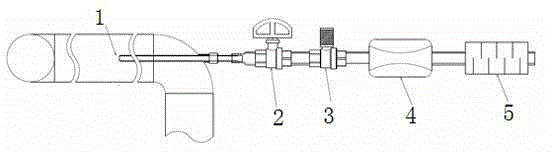

[0027] S1. Preparation 101 before testing: First, the compressed gas is sprayed for about five minutes according to the theoretically calculated flow rate, and the valve is closed; then, the air sampling connection is performed as follows: figure 2 As shown, a gas sampling port is established at the end of the air pipeline. After the sampling port, a sampling air pipe 1, a stop valve 2, a flow regulating valve 3, a flow meter 4, and a detector 5 are connected in series. The sampling air pipe 1 is set with a curved The sampling air pipe of the head, and the elbow is less than 30°;

[0028] S2. Dew point detection 102: To det...

Embodiment 2

[0037] In this embodiment, on the basis of Embodiment 1, the dew point analyzer in step S2 is a portable dew point analyzer, the inlet pressure is adjusted to 80-200 kPa, and the flow rate is controlled within the range of 2-4 L / min.

[0038] In this embodiment, the dew point analyzer is a portable dew point analyzer, the inlet pressure is adjusted to 80-200kPa, and the flow rate is controlled within the range of 2-4L / min, which is convenient for detection and control, and at the same time improves the efficiency of dew point detection and the accuracy of detection ;

Embodiment 4

[0040] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, in step S3, the area to be wiped each time is 0.1±0.01 square meters.

[0041] In this embodiment, white filter paper or lint-free cloth is used for wiping, and each wiping area is 0.1±0.01 square meters, which can effectively wipe off the oil stains in the wiping area and improve the accuracy of oil content detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com