Device for pressurizing and pressure maintaining anti-leak detection after corn harvester brake pump assembly

A corn harvester and detection device technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of heavy weight, unstable sub-pump pressure holding, and large size of the corn harvester, and achieves simple detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

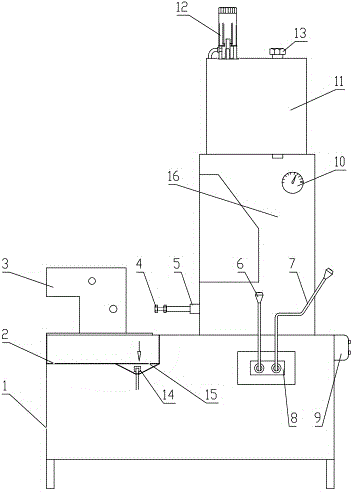

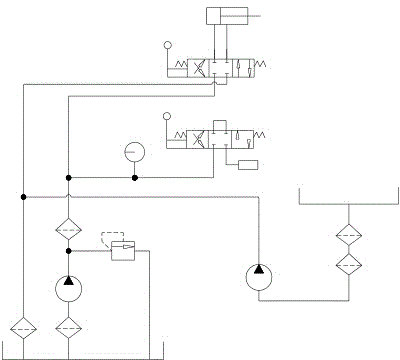

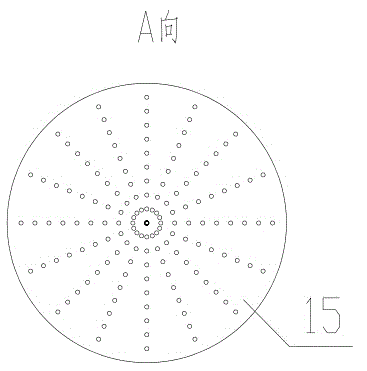

[0016] A pressure-holding and anti-leakage detection device for a brake pump of a corn harvester after assembly, comprising a base 1, one end of the base 1 is fixed with a fuel tank bracket 16, the other end is provided with a pump fixing fixture 3, and the pump fixing fixture 3 is provided with a Hydraulic oil recovery tank 2, the bottom of hydraulic oil recovery tank 2 is provided with oil return primary filter 15 and oil return secondary filter 14, and a multi-way valve group 8 is provided under the fuel tank bracket 16, and the multi-way valve group 8 is respectively operated with the master pump The handle 6 is connected with the sub-pump operating handle 7, the pressure gauge 10 is installed on the side of the fuel tank bracket 16, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com