Air flow drying device with double helix structure

A double-helix structure and air-flow drying technology, which is applied in drying chambers/containers, lighting and heating equipment, drying, etc., can solve problems such as installation, maintenance, and cleaning difficulties, the overall structure is not compact, and takes up a lot of space. Good performance, extended residence time, operational effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

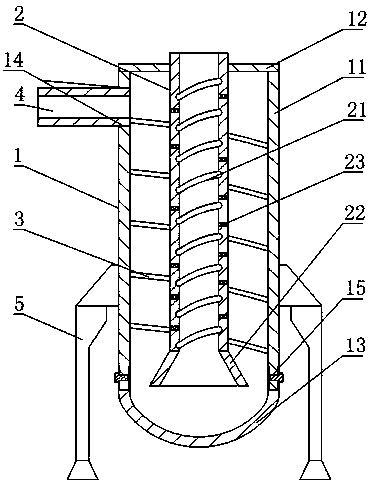

[0015] Such as figure 1 As shown, the airflow drying equipment with a double helix structure includes an outer drying cylinder 1 and an inner drying cylinder 2. The outer drying cylinder 1 includes an outer cylinder body 11 with openings at both ends of the upper and lower ends, and is fixedly connected to the upper end of the outer cylinder body 11 and The top cover 12 that closes the opening of the upper end of the outer cylinder 11, the bottom 13 that is fixedly connected to the lower end of the outer cylinder 11 and closes the opening of the lower end of the outer cylinder 11, and the upper part of the side wall of the outer cylinder 11 is provided with a feed port 14 that penetrates the side wall , the upper and lower ends of the inner drying cylinder 2 are open, the inner drying cylinder 2 is coaxially arranged with the outer cylinder body 11, the lower end opening is arranged in the outer cylinder body 11, the upper end opening passes through the top cover 12, and the ou...

Embodiment 2

[0017] On the basis of Embodiment 1, the present embodiment makes the following further limitations: the lower end of the inner drying cylinder 2 is provided with a conical cylinder 22 with a small upper part and a larger lower part, and the upper end surface of the conical cylinder 22 is connected with the lower end surface of the inner drying cylinder 2. Solid connection.

Embodiment 3

[0019] In this embodiment, the following further limitations are made on the basis of Embodiment 1; the inner drying cylinder 2 is provided with a first heating element 23 in the cylinder wall. In this embodiment, the first heating element 23 can choose to heat a metal wire, a metal rod, or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com