Special tee for test of sulfur hexafluoride gas and use method of tee

A technology of sulfur hexafluoride gas and sulfur hexafluoride, applied in measuring devices, branch pipelines, instruments, etc. Increase the workload of personnel and other issues to achieve the effect of preventing personnel from causing injury, simple structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

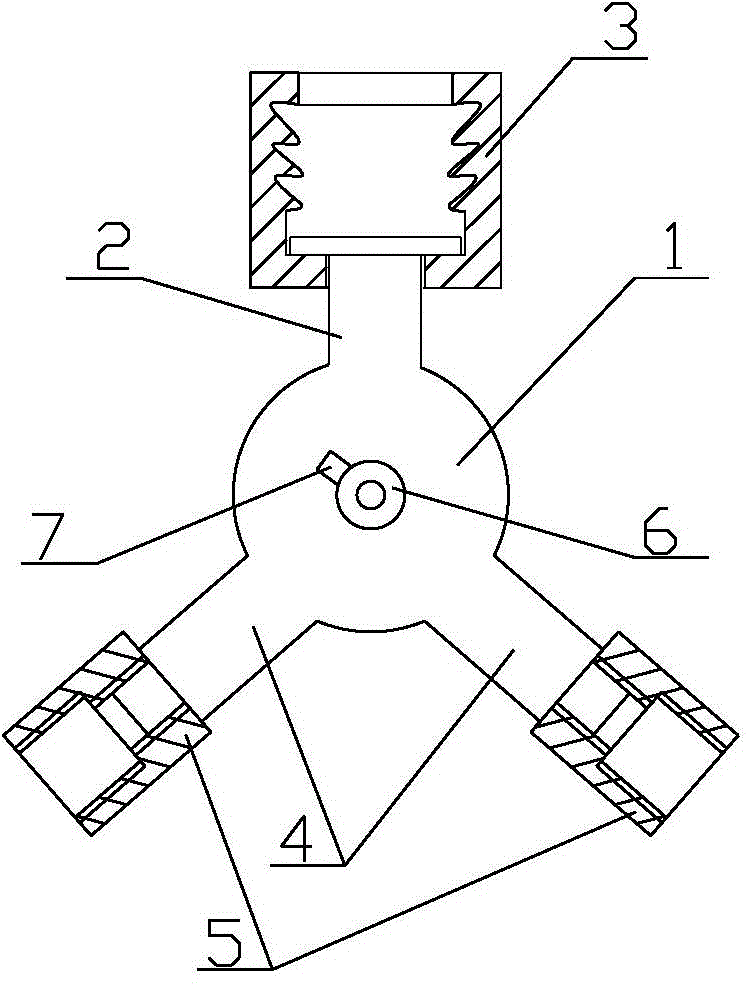

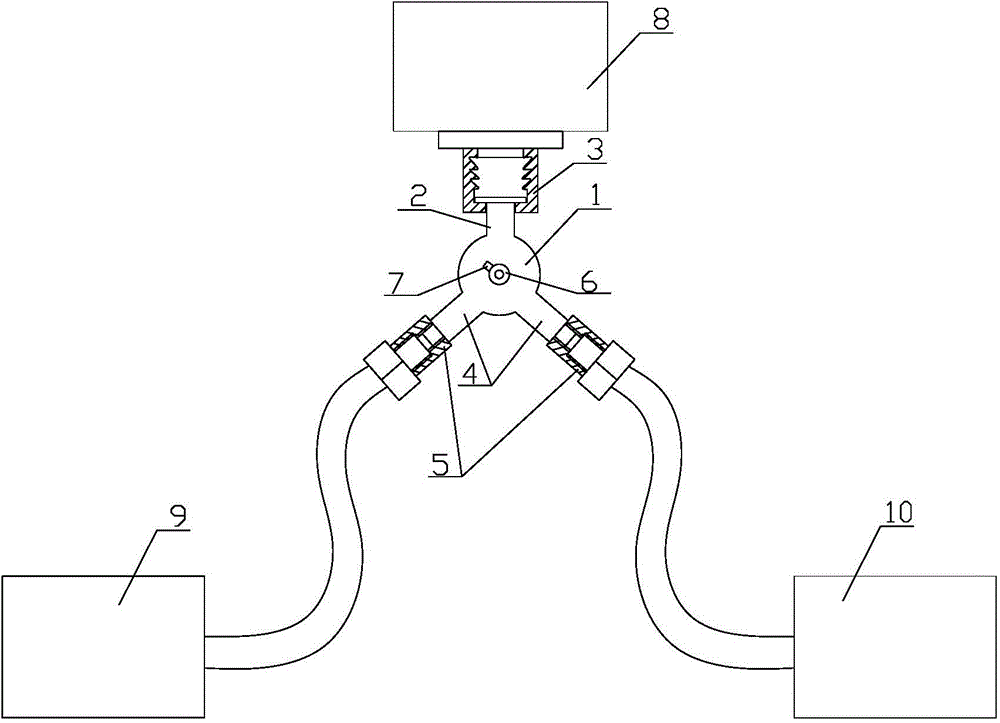

[0027] see figure 1 , Is a schematic diagram of the structure of a special tee for sulfur hexafluoride gas testing of the present invention. The special tee for sulfur hexafluoride gas testing of the present invention includes a hollow body 1, which is provided with One air inlet pipe 2 and two air outlet pipes 4, the ends of the air inlet pipe 2 and the air outlet pipe 4 are both provided with detachable adapters, and the hollow body 1 is also provided with an air release valve 6.

[0028] The hollow body 1 is made of chromium-nickel austenitic stainless steel or polyvinyl chloride.

[0029] The other end of the intake pipe conversion joint 3 is connected to the gas chamber interface of the electrical equipment 8 filled with sulfur hexafluoride, and has a joint form and specification that is compatible with the gas chamber interface of the connected equipment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com