Internal Directional Spin-rotation Impact Detonation Device for Completion of Oil and Gas Wells

A detonation device, oil and gas well technology, applied in the direction of wellbore/well components, production fluid, measurement, etc., can solve the problem that the direction of the jet flow of perforating bullets cannot be measured, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

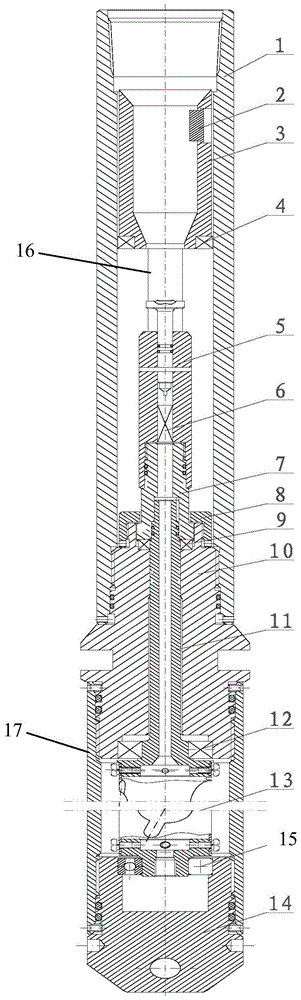

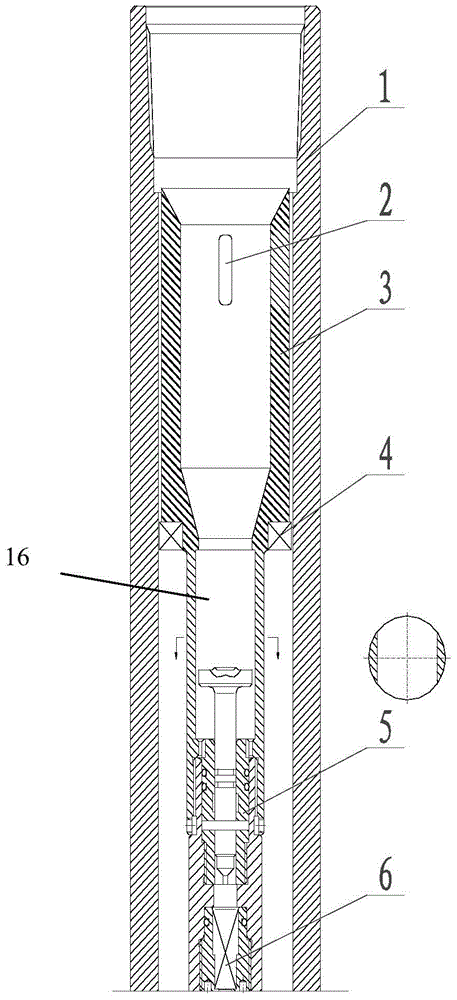

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0023] Such as Figure 1~2 As shown, the oil and gas well proposed by the present invention uses an internal directional self-rotating impact detonator, which is composed of an outer cylinder 1, an azimuth key 2, a guide sleeve 3, a central bearing 4, an impact detonator 5, a detonator 6, and a directional connecting pipe 7. Union 8, fixed bearing 9, even gun joint 10, locating plate 11, support bearing 12, partial weight bullet frame 13, gun tail 14 forms. The azimuth key 2 is fixed on the upper end of the guide sleeve 3 by welding, the guide sleeve 3 is the upper part of the percussion initiation device 5, the detonator 6 is placed inside the lower end of the percussion detonation device 5, and the lower end of the percussion detonation device 5 is connected with the directional connecting pipe 7 at the same time, and the guide The outer upper end of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com