A Double Cantilever Construction Method for Extremely Asymmetric Composite Beams

A construction method and technology of composite beams, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of reduced bridge structure safety and durability, bridge alignment deviation, large difference in quality of concrete beams and mixed beams, etc. Achieve the effect of reducing construction cost, shortening construction period, and reducing settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

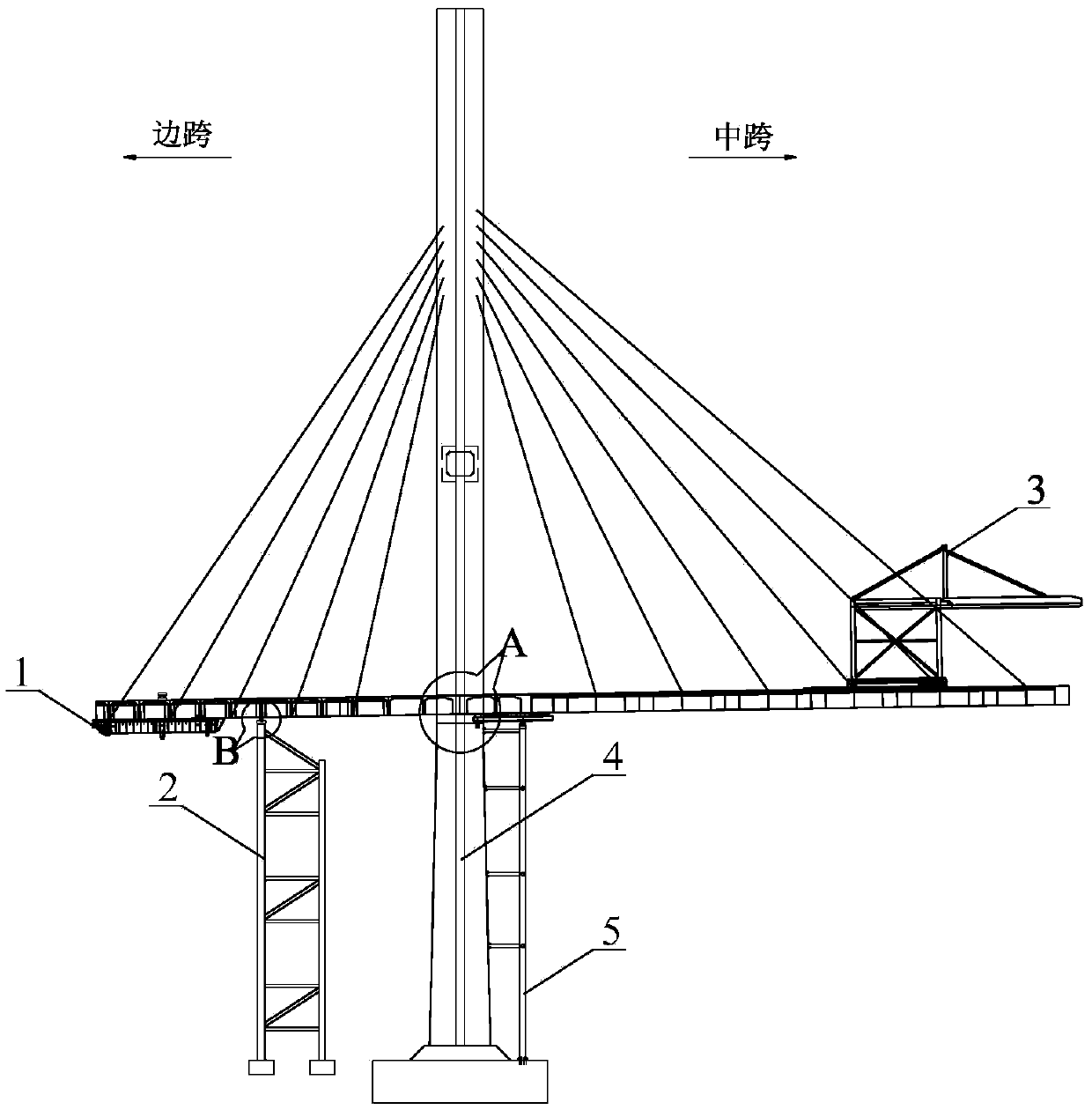

[0039] see figure 1 As shown, the embodiment of the present invention provides a double-cantilever construction method for an extremely asymmetric composite beam, including the following steps:

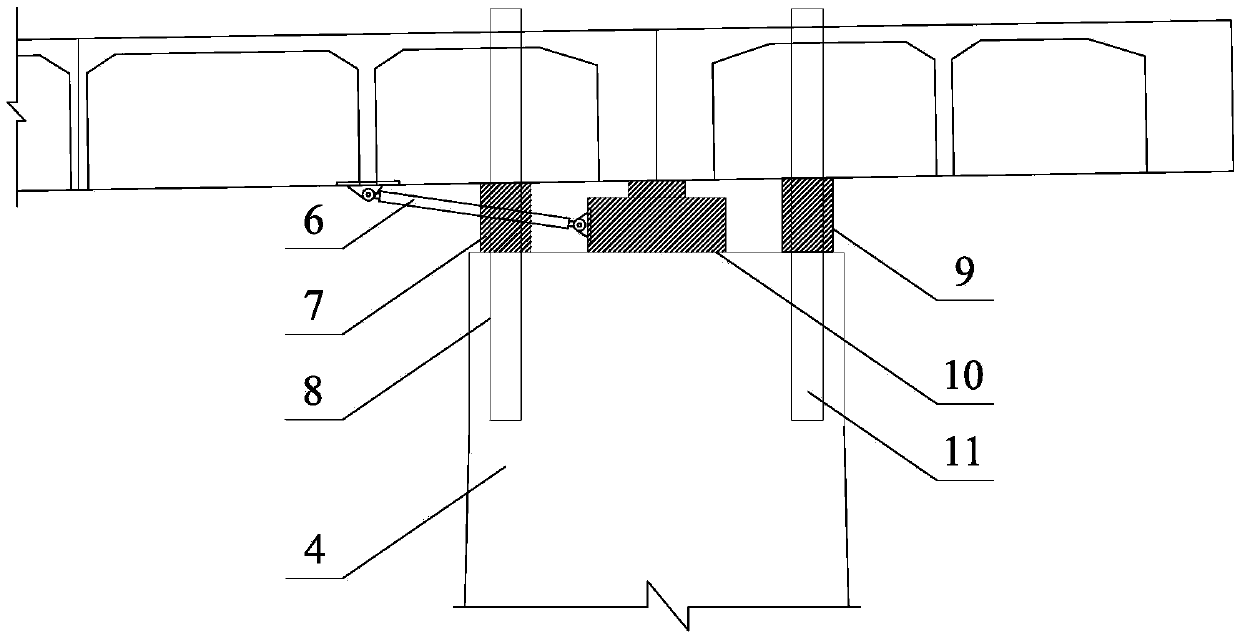

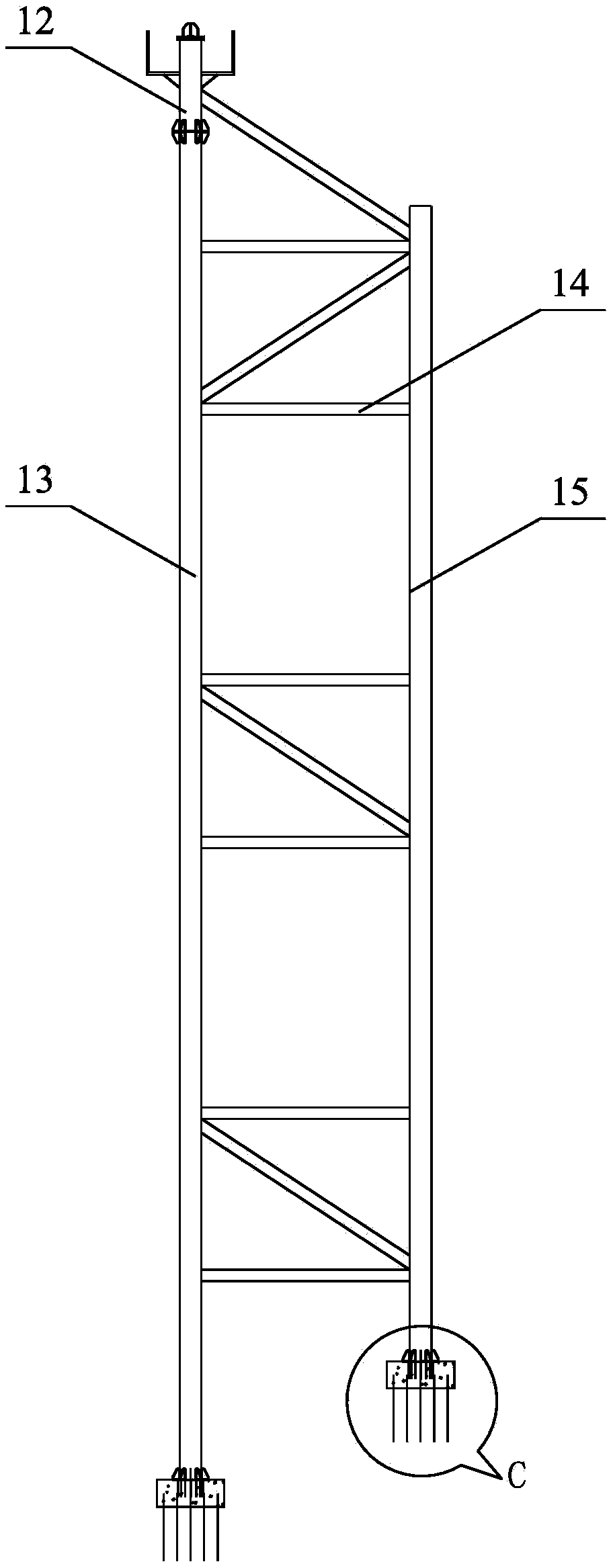

[0040] S1: Prefabricate several steel girders, steel girder bridge decks, the first finish-rolled rebar 8 and the second finish-rolled rebar 11, and build the lower tower column 4 of the cable-stayed bridge to be erected, see figure 2 As shown, in the process of building the lower tower column 4, the bottom ends of the first finish-rolled rebar 8 and the second finish-rolled rebar 11 are inserted into the inside of the lower tower column 4; The first temporary bearing 7, the bearing pad stone 10 and the second temporary bearing 9, the existing permanent bearing is set on the top of the bearing pad stone 10.

[0041] The area where the main beam is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com