Preparation method of reactive dye dyeing hydrophilic color-fixing agent

A technology of reactive dyes and color-fixing agents, which is applied in dyeing, textiles and papermaking, can solve problems such as poor color fixing effect, failure to achieve hygroscopicity, and decreased hydrophilicity of cotton fabrics, so as to improve wet rubbing fastness. High degree, small color change, excellent color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] In a preferred embodiment, the preparation method of the reactive dye dyeing hydrophilic fixing agent of the present invention includes:

[0012] (1) Provide polymerized monomers, based on the total mass of the monomers, the monomers include 75-85% of amine monomers, 10-20% of vinyl pyridine and 2-5% of (meth)acrylic acid Class monomer

[0013] (2) Polymerizing amine monomers and (meth)acrylic monomers in the presence of a mixture of free radical initiators and optional co-initiators at a temperature of 50-85°C,

[0014] (3) Vinylpyridine is added to the reaction product of step (2) at a temperature of 55-85°C, and the polymerization reaction is continued to obtain the hydrophilic fixing agent.

[0015] In some preferred embodiments, the amine monomers include, but are not limited to, aminoethylpiperazine (AEP), triethylenetetramine (TETA), tetraethylenepentamine (TEPA), ethyleneimine, propyleneimine , One or a combination of diallylamine hydrochloride and triallylamine hydroc...

Embodiment 1

[0045] At room temperature, 80g aminoethylpiperazine, 100g triallylamine hydrochloride, 10g acrylic acid, 50g ethanol, 700g water are mixed uniformly, heated to 35°C and kept for 15min, continue to increase to 60°C, and keep the temperature for 15min. At the beginning, ammonium persulfate solution (0.9g ammonium persulfate dissolved in 18g water) and polyamide-amine solution (0.25g PAMAM-G2 dissolved in 12g water) were added dropwise at the same time, and 30g 2-vinylpyridine was added 15 minutes later. The dripping time of the ammonium persulfate solution and the polyamide-amine solution was about 2.0 h each, and the dripping was completed at the same time. The temperature was raised to 80°C, and the reaction was kept for 3 hours. Cooling, discharging, a light yellow transparent liquid is prepared, which is a hydrophilic fixing agent.

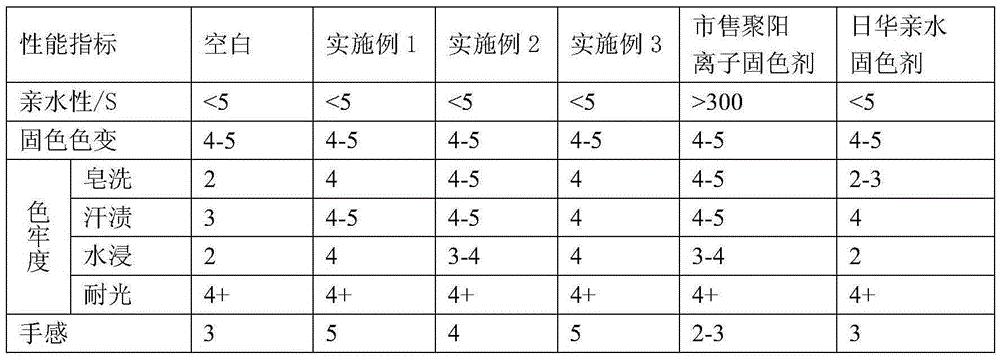

[0046] The application results of fixing performance, hydrophilicity and hand feeling are shown in Table 1.

Embodiment 2

[0048] Mix 50g aminoethylpiperazine, 45g propylene imine, 110g diallylamine hydrochloride, 10g methacrylic acid, 30g ethanol, 700g water at room temperature, heat to 35℃ and keep it for 15min, continue to heat up to 55 ℃, keep the temperature for 15 min. At the beginning, potassium persulfate solution (0.8g potassium persulfate dissolved in 18g water) and polyamide-amine solution (0.2g PAMAM-G3 dissolved in 12g water) were added dropwise at the same time. After 15 minutes, 25g 2-vinylpyridine was added. The dripping time of the potassium persulfate solution and the polyamide-amine solution is about 2.5 hours each, and the dripping ends at the same time. The temperature was raised to 70°C, and the reaction was kept for 4 hours. Cooling, discharging, a light yellow transparent liquid is prepared, which is a hydrophilic fixing agent. The application results of fixing performance, hydrophilicity and hand feeling are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com