A kind of fabric softener and preparation method thereof

A fabric softener and softener technology, which is applied in textiles and papermaking, wear-resistant fibers, and improved hand-feeling fibers, etc. It can solve the problems of heavy sticky feeling of clothes, not refreshing enough to feel, and low reinforcement effect, and achieve stickiness Low sensitivity, good hardness ion tolerance, wide antibacterial spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

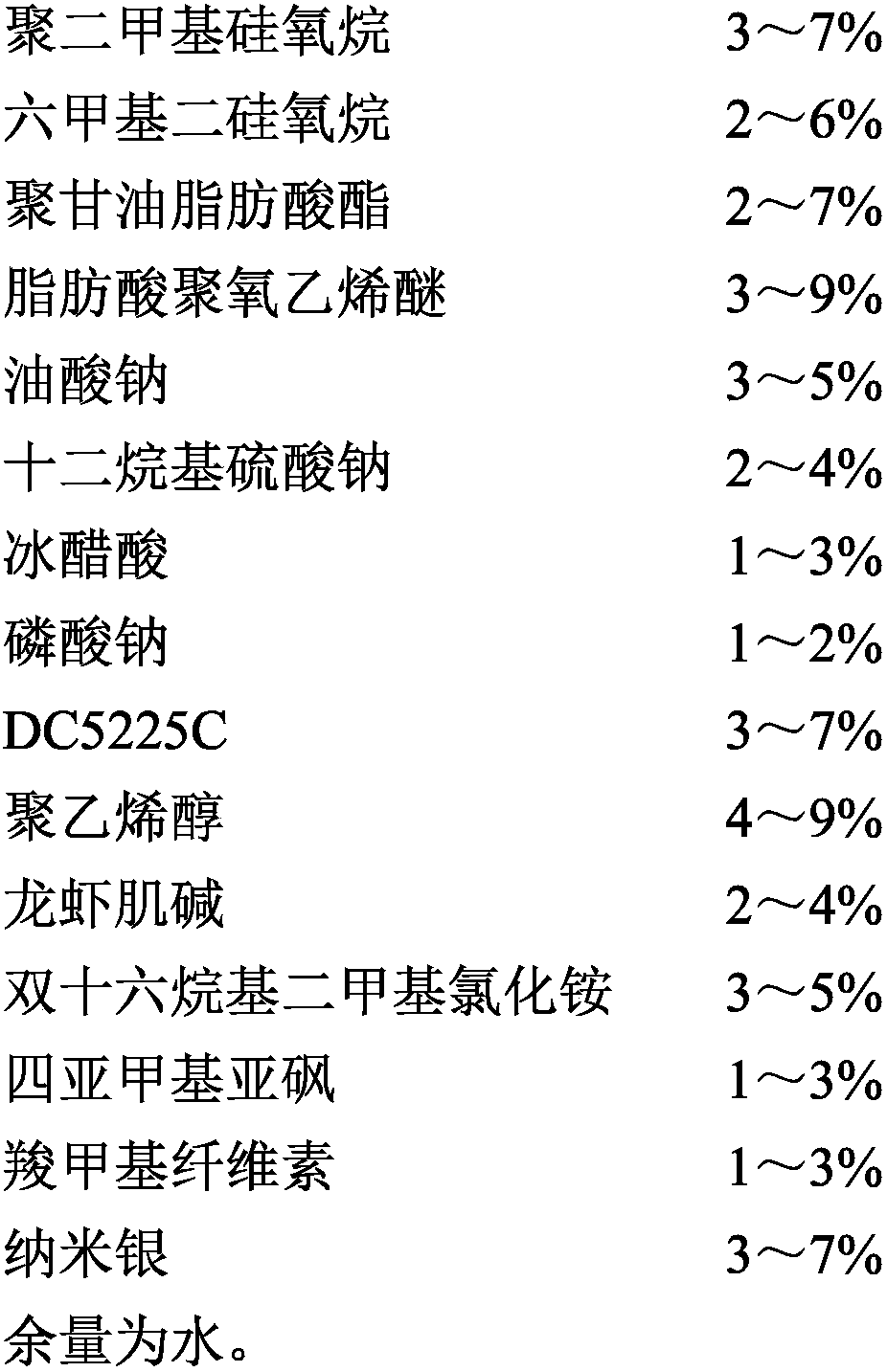

[0043] A kind of fabric softener of embodiment 1

[0044] Formula, each 100g contains:

[0045]

[0046]

[0047] Wherein the average particle diameter of nano silver is 25nm.

[0048] The preparation method comprises the following steps:

[0049](1) Take 40g of water and heat it to 68°C, then add 3g of polydimethylsiloxane, 6g of hexamethyldisiloxane, 9g of fatty acid polyoxyethylene ether, 3g of dihexadecyldimethyl Ammonium chloride and 9g polyvinyl alcohol are dissolved completely to obtain solution A;

[0050] (2) After the solution A obtained in step (1) is subjected to ultrasonic dispersion treatment, after cooling to 40° C., solution B is obtained;

[0051] (3) Add 2g polyglycerol fatty acid ester, 3g sodium oleate, 4g sodium lauryl sulfate, 1g carboxymethylcellulose and 3gDC5225C to the solution B obtained in step (2) while stirring until completely dissolved, After cooling to 30°C, solution C was obtained;

[0052] (4) Add 1g of glacial acetic acid, 1g of s...

Embodiment 2

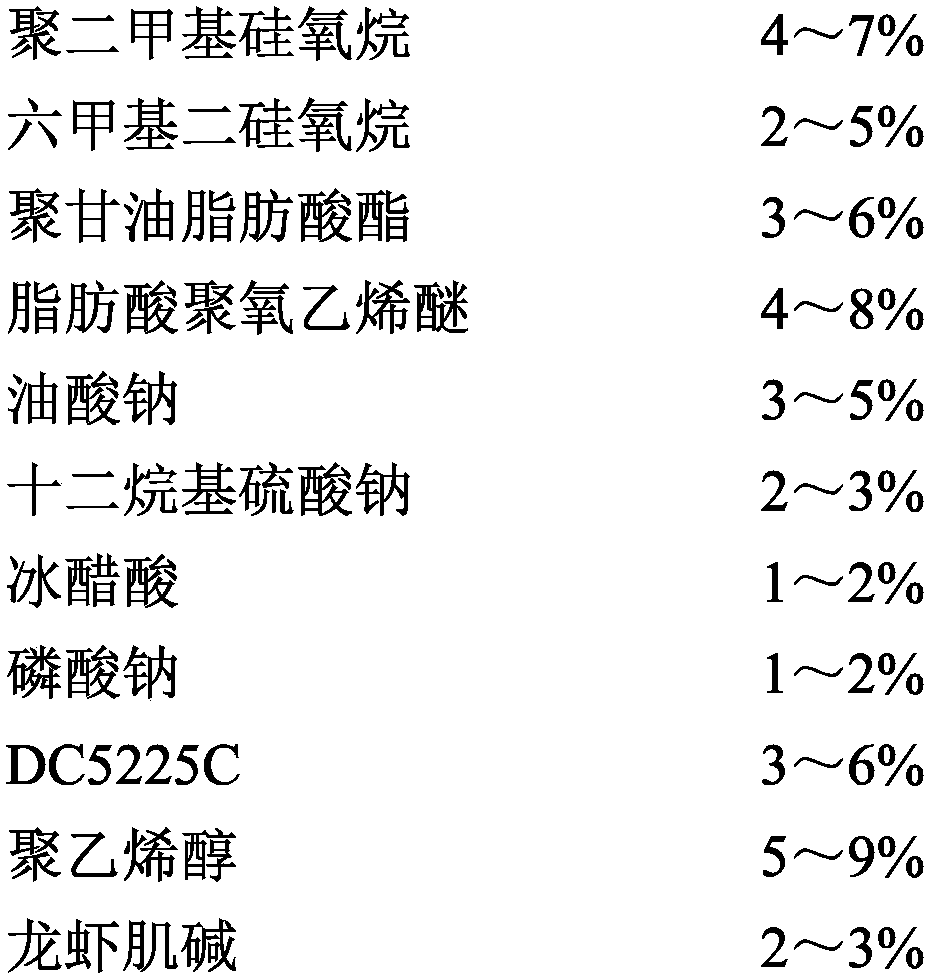

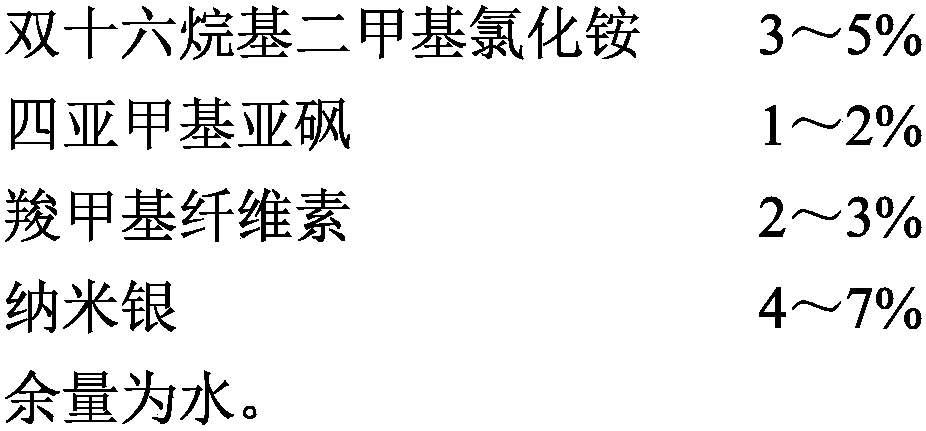

[0053] Embodiment 2 A fabric softener

[0054] Formula, each 100g contains:

[0055]

[0056]

[0057] Wherein the average particle diameter of nano silver is 40nm.

[0058] Preparation method is basically the same as embodiment 1, and the difference with embodiment 1 is:

[0059] Step (1) is heated to 82°C; step (2) is cooled to 48°C; step (3) is cooled to 38°C.

Embodiment 3

[0060] Embodiment 3 a kind of fabric softener

[0061] Formula, each 100g contains:

[0062]

[0063]

[0064] Wherein the average particle diameter of nano-silver is 30nm.

[0065] Preparation method is basically the same as embodiment 1, and the difference with embodiment 1 is:

[0066] Step (1) heating to 72°C; step (2) cooling to 44°C; step (3) cooling to 32°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com