Surface anticorrosion wear-resistant composite coating for cylinder sleeve of automobile engine applying bio-oil

An automobile engine and composite coating technology, which is applied in coating, metal material coating process, liquid chemical plating, etc., can solve the problem of not meeting the requirements of automobile engine cylinder liner surface protection, low coating density, coating Easy to fall off and fail to solve problems such as cracking, peeling and wear, improve density, and improve long-term anti-corrosion and wear-resisting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

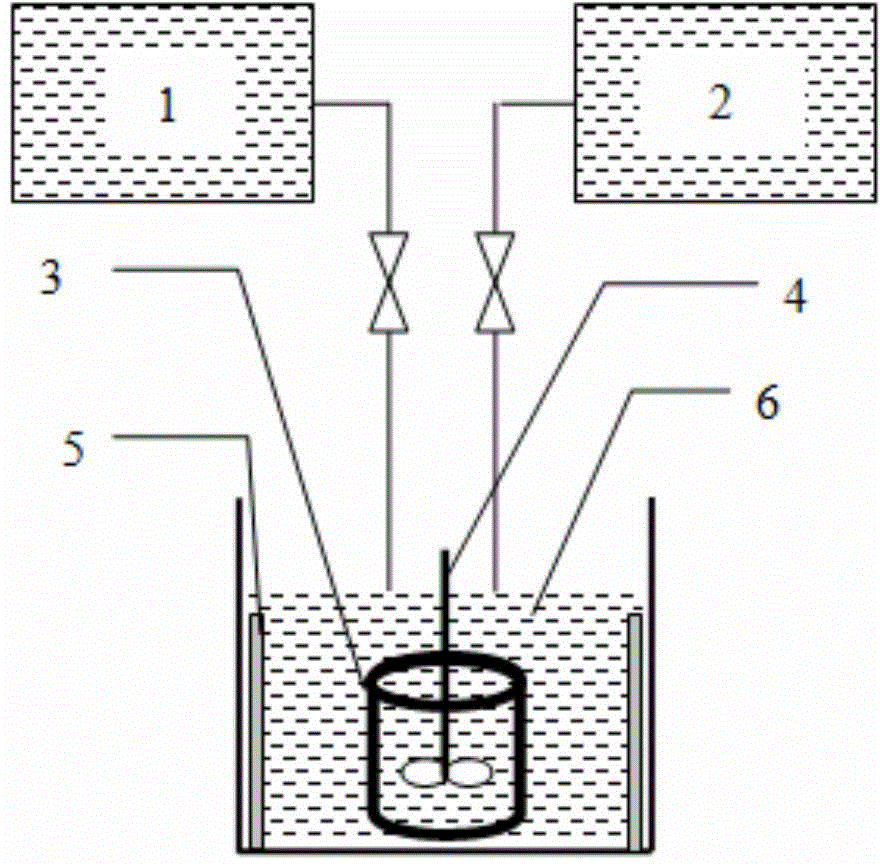

Method used

Image

Examples

example 1

[0022] First prepare lye 10L: NaOH 2g·L -1 , NaHCO 3 8g·L -1 , Na 3 PO 4 12H 2 O 1.2g L -1 , Na 2 SiO 3 7g·L -1 , OP-200.3g·L -1 . Reconstitute 10L of acid solution: 0.2mol·L -1 h 2 SO 4 Solution 5L and 0.2mol·L -1 Mixed acid solution of HCl solution 5L. Heat the lye and acid to 70°C. Soak the cylinder liner of the engine to be treated in lye for 5 minutes to remove oil, then take out the cylinder liner and wash it with deionized water until the solution is neutral after washing, then soak it in acid solution for 5 minutes to remove rust, take it out and use it in the same way Wash with ionic water until the solution is neutral after washing, and complete the pre-treatment of degreasing and derusting the cylinder liner.

[0023] Put the pre-treated cylinder liner vertically into the cylinder opening liquid, the composition of the cylinder opening liquid: NiSO 4 5g·L -1 , CuSO 4 5g·L -1 , Ce(NO 3 ) 3 10g·L -1 , La(NO 3 ) 3 12 g· L -1 , C 6 h 5 Na 3...

example 2

[0026] First prepare lye 10L: NaOH 4g·L -1 , NaHCO 3 6g·L -1 , Na 3 PO 4 12H 2 O 1g L -1 , Na 2 SiO 3 7.5g·L -1 , OP-200.4g·L -1 . Reconstitute 10L of acid solution: 0.1mol·L -1 h 2 SO 4 Solution 5L and 0.3mol·L -1 Mixed acid solution of HCl solution 5L. Heat the lye and acid to 75°C. Soak the cylinder liner of the engine to be treated in lye for 4 minutes to remove oil, then take out the cylinder liner and wash it with deionized water until the solution is neutral after washing, then soak it in acid solution for 6 minutes to remove rust, take it out and use it in the same way Wash with ionic water until the solution is neutral after washing, and complete the pre-treatment of degreasing and derusting the cylinder liner.

[0027] Put the pre-treated cylinder liner vertically into the cylinder opening liquid, the composition of the cylinder opening liquid: NiSO 4 8g·L -1 , CuSO 4 6g·L -1 , Ce(NO 3 ) 3 14g·L -1 , La(NO 3 ) 3 8g·L -1 , C 6 h 5 Na 3 o ...

example 3

[0030] The preprocessing part is the same as Example 2.

[0031] Put the pre-treated cylinder liner vertically into the cylinder opening liquid, the composition of the cylinder opening liquid: NiSO 4 10g·L -1 , CuSO 4 8g·L -1 , Ce(NO 3 ) 3 16g·L -1 , La(NO 3 ) 3 8g·L -1 , C 6 h 5 Na 3 o 7 2H 2 O 10g·L -1 , C 3 h 6 o 3 28g·L -1 ; The continuous phase composition is: NaH containing 2.2% Graphene in mass percent 2 PO 2 ·H 2 O(58g·L -1 ) solution; the volume of the open cylinder liquid and the continuous phase solution is 9L, and the continuous phase drip rate is 300mL min -1 The pH regulator is NaOH solution with a mass percentage of 40%, and the pH is controlled at 4.5-4.6 for the first 10 minutes, kept at 6.5-6.6 for the middle 10 minutes, and kept at 8.5-8.6 for the last 10 minutes; the temperature of the plating solution is kept at 92 ° C, and the stirring speed is 500 rpm. When finished, remove the cylinder liner and let it dry.

[0032] Then heat and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com