Electrolytic capacitor casing heat radiating coating containing graphene material

A technology of electrolytic capacitors and heat-dissipating coatings, applied in the direction of coatings, etc., can solve the problems of unstable power supply of electronic components, aging of electrolytic capacitors, and hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

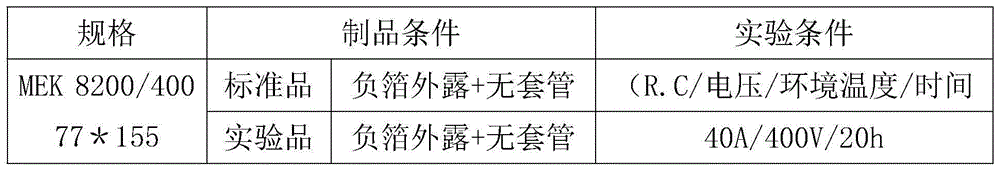

Image

Examples

Embodiment 1

[0027] A heat-dissipating coating for electrolytic capacitor shells containing graphene materials, consisting of the following components: 30 kg of macroporous adsorption resin, 10 kg of silicon carbide, 5 kg of amorphous quartz particles, 2 kg of potassium feldspar, 5 kg of tert-butanol kg, 10 kg of graphene, 2 kg of boron fiber, 2 kg of carbon fiber, 2 kg of potassium tungstate, 5 kg of pigment, 50 kg of deionized water, 2 kg of trilead tetroxide, 3 kg of rare earth, 2 kg of chloroplatinic acid, modified 5 kg of permanent corn starch, 0.5 kg of cobalt (II) selenide;

[0028] The preparation process of above-mentioned heat-dissipating coating is:

[0029] 1) Weigh each raw material according to the above ratio, and use absolute ethanol as the dispersion medium for silicon carbide, amorphous quartz particles, potassium feldspar, trilead tetroxide, and rare earth, wherein the mass ratio of material to ethanol is 1:20, Ultrasonic dispersion on an ultrasonic cleaning machine for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com