uv-laser transfer coating composition and use thereof

A technology of laser transfer and composition, applied in the field of coatings, can solve the problems of lack of information, light transmission and whiteness, and UV coating cannot be peeled off very well, and achieves the effects of good printing adaptability, good film-forming and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

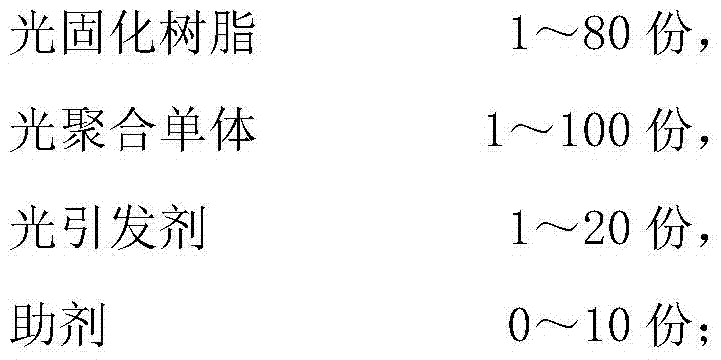

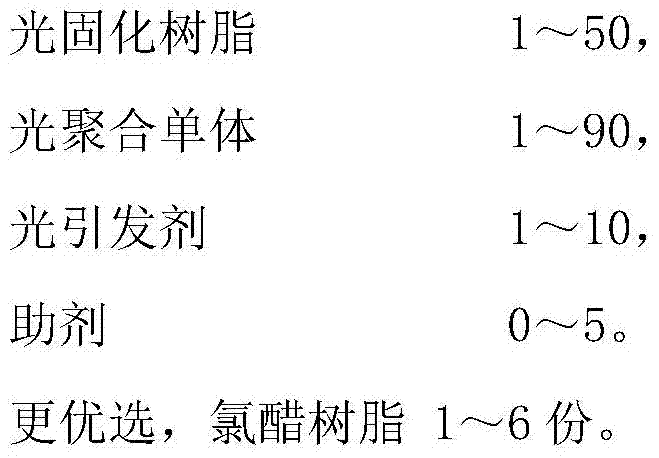

[0044] Embodiment 1~5 provides a kind of UV-laser transfer coating composition respectively, comprises A component and B component;

[0045] The preparation method of described A component comprises the steps:

[0046] (a) prepare materials according to the components and parts by weight shown in Table 1;

[0047] (b) Mix the raw material components corresponding to each embodiment according to their parts by weight, disperse at a medium speed for 2 hours, and filter to obtain final product.

[0048] A component and parts by weight thereof in the UV-laser transfer coating composition of table 1

[0049]

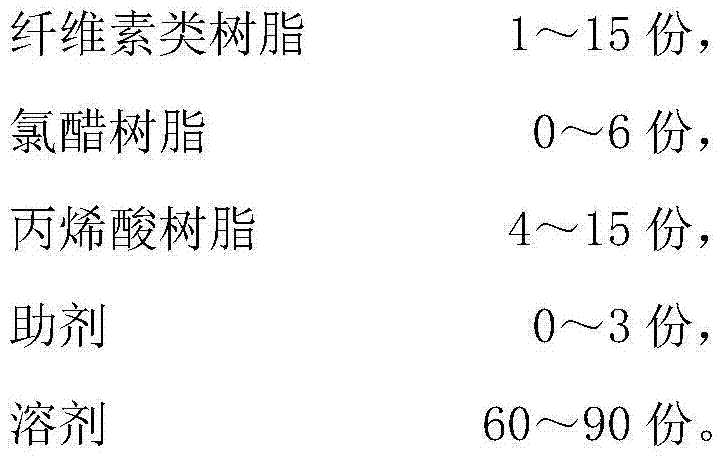

[0050] The preparation method of the B component comprises the following steps:

[0051] (1) Prepare raw materials according to the components and parts by weight shown in Table 2:

[0052] (5) first place the solvent in the reaction kettle, open the stirring device, and mix evenly;

[0053] (6) Resin component (vinyl chloride resin, acrylate resin and cellulose resin) i...

Embodiment 6

[0058] Embodiment 6, application

[0059] This embodiment relates to the use of the UV-laser transfer coating composition of Examples 1-5 in preparing a UV-laser transfer film.

[0060] Described preparation comprises the steps:

[0061] (1) The first coating process

[0062] According to the requirements of viscosity, coating amount and coating effect of the UV-laser transfer coating composition, use the coating machine to evenly coat the B-component of the UV-laser transfer coating composition on the base film On, by adjusting the process parameters, to ensure that the B component of the UV-laser transfer coating composition is evenly coated;

[0063] (2) Drying process

[0064] Control the temperature, humidity, speed and other process parameters of the drying tunnel to ensure the drying of the B-component coating of the UV-laser transfer coating composition;

[0065] (3) The second coating process

[0066] Use the coating machine to evenly coat the A component of th...

Embodiment 7

[0076] Embodiment 7, performance detection

[0077] In order to compare the present invention with the coatings of the prior art, the following methods are used for coating, and the flatness, adhesion, aluminizing fastness, proof appearance, and temperature resistance of the coating are measured.

[0078] 1. Flatness

[0079] Coat component B of the UV-laser transfer coating composition on the PET film with a scraper coating method, bake and dry the film and then coat component A on it, and check the coating flatness of the proof sheet visually.

[0080] Test method: Visually observe the appearance of the test sample.

[0081] Evaluation method: the surface of the sample sheet is smooth and flat as excellent, and the surface is uneven and wrinkled as poor.

[0082] 2. Metastasis

[0083] Apply component B of the UV-laser transfer coating composition on the PET film by scraping method, bake and dry the film and then coat component A on it, and press the pattern of the embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com