Antioxidant polyether polyol and preparation method thereof

A technology for polyether polyol and oxidizing polyether, which is applied in the field of polyether synthesis, can solve the problems of changing chemical properties, reducing the storage period of polyether polyol, etc., and achieves the effects of reducing usage, scientific and reasonable preparation method, and increasing benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

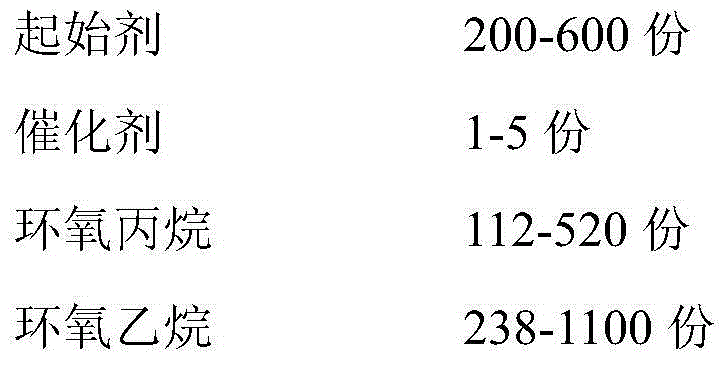

Method used

Image

Examples

Embodiment 1

[0019] (1) Accurately weigh 100g of o-phenylenediamine, 100g of sorbitol and 1.1g of potassium hydroxide catalyst, and transfer them into a 3L reaction kettle.

[0020] (2) Stirring was started, nitrogen was replaced 6 times, and the temperature was slowly raised to 40° C. to dissolve until homogeneous.

[0021] (3) Continue to heat up to 85° C., slowly drop in 15 g of propylene oxide and stop feeding.

[0022] (4) After the reaction starts, add the remaining 97g of propylene oxide by continuous feeding method, and after aging at 105°C for 7 hours, add 238g of ethylene oxide by continuous feeding method to prepare crude polyether. The reaction temperature is 85°C, the reaction is 25h, and the reaction pressure is controlled to be <0.2MPa.

[0023] (5) Cool the crude polyether to 85°C, add water and phosphoric acid, and adjust the pH to 7.0.

[0024] (6) Add magnesium silicate or aluminum silicate for adsorption, raise the temperature to 110° C., pass nitrogen to evacuate to ...

Embodiment 2

[0027] (1) Accurately weigh 400g of o-phenylenediamine, 200g of sorbitol and 3g of hexachlorocyclotriphosphazene, and transfer them into a 5L reaction kettle.

[0028] (2) Stirring was started, nitrogen was replaced 8 times, and the temperature was slowly raised to 70° C. to dissolve until homogeneous.

[0029] (3) Continue to heat up to 85° C., slowly drop in 20 g of propylene oxide and stop feeding.

[0030] (4) After the reaction starts, add the remaining 500g of propylene oxide by continuous feeding method, and after aging at 105°C for 7 hours, add 1100g of ethylene oxide by continuous feeding method to prepare polyether. The reaction temperature is 100° C., the reaction is 18 hours, and the reaction pressure is controlled to be <0.2 MPa.

[0031] (5) Cool the crude polyether to 85°C, add water and phosphoric acid, and adjust the pH to 7.0.

[0032] (6) Add magnesium silicate or aluminum silicate for adsorption, raise the temperature to 110° C., pass nitrogen to evacuate...

Embodiment 3

[0035] (1) Accurately weigh 300g of o-phenylenediamine, 100g of sorbitol and 5g of hexachlorocyclotriphosphazene, and transfer them into a 5L reaction kettle.

[0036] (2) Stirring was started, nitrogen was replaced 10 times, and the temperature was slowly raised to 60° C. to dissolve until homogeneous.

[0037] (3) Continue to heat up to 85° C., slowly drop in 20 g of propylene oxide and stop feeding.

[0038] (4) After the reaction starts, add the remaining 332g of propylene oxide by continuous feeding method, and after aging at 105°C for 7 hours, add 748g of ethylene oxide by continuous feeding method to prepare polyether. The reaction temperature is 115°C, the reaction is 20h, and the reaction pressure is controlled to be <0.2MPa.

[0039] (5) Cool the crude polyether to 85°C, add water and phosphoric acid, and adjust the pH to 7.0.

[0040] (6) Add magnesium silicate or aluminum silicate for adsorption, raise the temperature to 110° C., pass nitrogen to evacuate to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com