Polyisocyanurate modified highly flame-retardant polyurethane spraying material and preparation method thereof

A technology of polyisocyanurate and spraying materials, which is applied in the field of polyurethane foam materials, can solve problems such as unsatisfactory effects and complicated processes, and achieve improved heat resistance and flame penetration resistance, low combustion smoke, and overcoming The effect of material brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

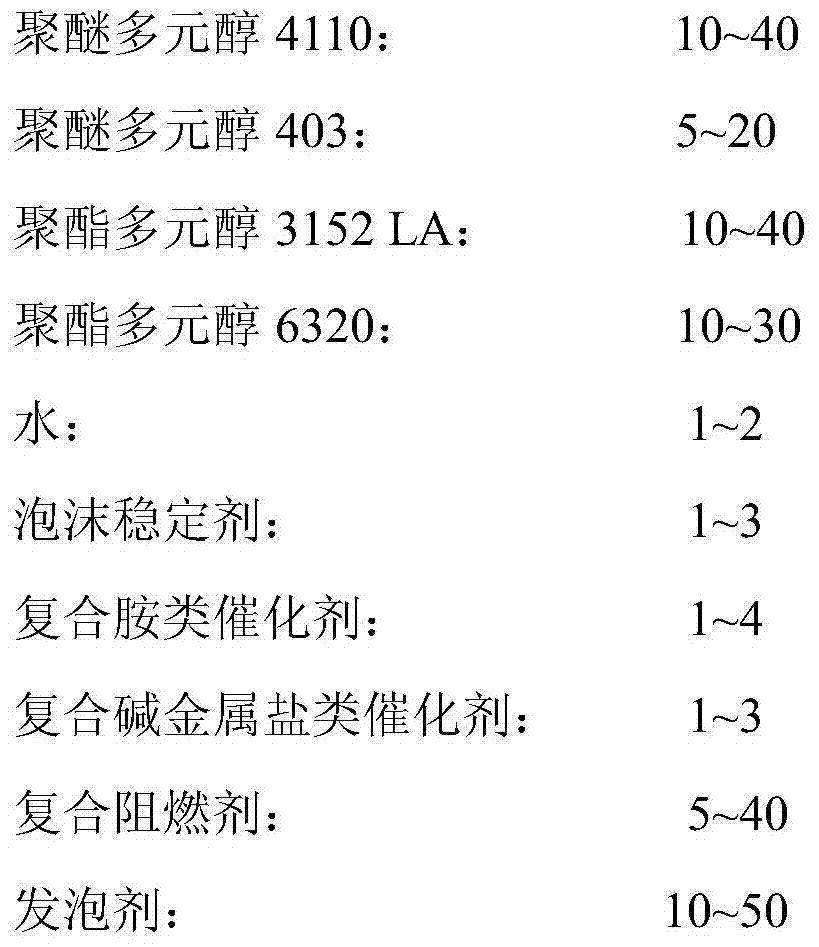

[0034] Prepare 163 kg of component A material, weighing respectively: 30 kg of polyether polyol 4110, 15 kg of polyether polyol 403, 30 kg of polyester polyol 3152LA, 25 kg of polyester polyol 6320, 1 kg of water, stable foam Agent Niax*Silicone L-69522 kg, composite amine catalyst 3 kg (Polycat 5, Polycat 41 and Dabco PT303, the weight ratio between the three is 2:1.5:1), composite alkali metal salt catalyst 2 kg (Polycat 46 , Dabco K-15 and RAYNOL PC-3932, the weight ratio between the three is 1:1:2), composite flame retardant 25 kg (TDCPP and DMMP weight ratio is 1:1), blowing agent 141B 30 kg . Put the weighed polyether polyol and polyester polyol into a mixing tank and stir evenly at room temperature. After the sampling test is qualified, it can be loaded into barrels.

[0035] When in use, the components A and B are pumped into the spray gun by two pumps according to the weight ratio of A:B=1:1.5 and then sprayed. The performance indicators of the prepared foam part are...

Embodiment 2

[0040] Prepare 174 kg of A-component material, weighing respectively: 30 kg of polyether polyol 4110, 10 kg of polyether polyol 403, 30 kg of polyester polyol 3152LA, 30 kg of polyester polyol 6320, 1 kg of water, stable foam Agent Niax*Silicone L-6952 2 kg, composite amine catalyst 4 kg (Polycat 5, Polycat 41 and Dabco PT303, the weight ratio between the three is 2:1.5:1), composite alkali metal salt catalyst 2 kg (Polycat 46. Dabco K-15 and RAYNOL PC-3932, the weight ratio between the three is 1:1:2), composite flame retardant 30 kg (TDCPP and DMMP weight ratio is 1:1), foaming agent 141B 35 Kilogram. Put the weighed polyether polyol and polyester polyol into a mixing tank and stir evenly at room temperature. After the sampling test is qualified, it can be loaded into barrels.

[0041] When in use, the components A and B are pumped into the spray gun by two pumps according to the weight ratio of A:B=1:1.5 and then sprayed. The performance indicators of the prepared foam p...

Embodiment 3

[0046] Prepare 196 kg of A-component material, weighing respectively: 35 kg of polyether polyol 4110, 10 kg of polyether polyol 403, 25 kg of polyester polyol 3152LA, 30 kg of polyester polyol 6320, 1.5 kg of water, stable foam Agent Niax*Silicone L-6952 2.5 kg, complex amine catalyst 4 kg (Polycat 5, Polycat 41 and DabcoPT303, the weight ratio between the three is 2:1.5:1), complex alkali metal salt catalyst 3 kg (Polycat 46 , Dabco K-15 and RAYNOL PC-3932, the weight ratio between the three is 1:1:2), composite flame retardant 40 kg (TDCPP and DMMP weight ratio is 0.5:1), blowing agent 141B 45 kg . Put the weighed polyether polyol and polyester polyol into a mixing tank and stir evenly at room temperature. After the sampling test is qualified, it can be loaded into barrels.

[0047] When in use, the components A and B are pumped into the spray gun by two pumps according to the weight ratio of A:B=1:1.5 and then sprayed. The performance indicators of the prepared foam part a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com