Core-shell foamed concrete insulating brick and preparation method thereof

A technology of insulating bricks and concrete, which is applied in the field of building materials, can solve the problems of poor impact resistance and poor durability, and achieve the effects of stable product quality, good wind pressure resistance, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing core foamed concrete insulation brick, is characterized in that, comprises the following steps:

[0023] (1) prepare hollow brick, described hollow brick is cement hollow brick, after the cement hollow brick is poured into molding, it is standby;

[0024] (2) prepare cement foam material;

[0025] a. Stir 150 parts of water and 30 parts of cement in proportion at a speed of 40 to 50 rpm to form a slurry;

[0026] b. Mix 1 part of naphthalenesulfonate formaldehyde condensate, 1 part of calcium chloride, 0.5 part of aluminum sulfate, 0.1 part of sodium stearate, 20 parts of hydrogen peroxide, and 1 part of sodium sulfate to prepare a foam solution;

[0027] c. Add the foam liquid prepared in step b to the slurry prepared in step a, and stir for 10 to 15 seconds under the condition of a rotating speed of 40 to 50 rpm to obtain a cement foam material;

[0028] (3) Preparing thermal insulation bricks, filling the cement foam material obtained in step...

Embodiment 2

[0030] A method for preparing a core foamed concrete insulation brick, other production steps are the same as in Example 1, and the cement foam material used is: 40 parts of cement, 2 parts of naphthalenesulfonate formaldehyde condensate, 2 parts of calcium chloride, 1 part of aluminum sulfate, 1 part of sodium stearate, 25 parts of hydrogen peroxide, 2 parts of sodium sulfate, and 200 parts of water.

Embodiment 3

[0032] A method for preparing core foamed concrete insulation bricks, other production steps are the same as in Example 1, the cement foaming material used is: 36 parts of cement, 2 parts of naphthalenesulfonate formaldehyde condensate, 1 part of calcium chloride, 1 part of aluminum sulfate, 0.5 parts of sodium stearate, 20 parts of hydrogen peroxide, 2 parts of sodium sulfate, and 180 parts of water.

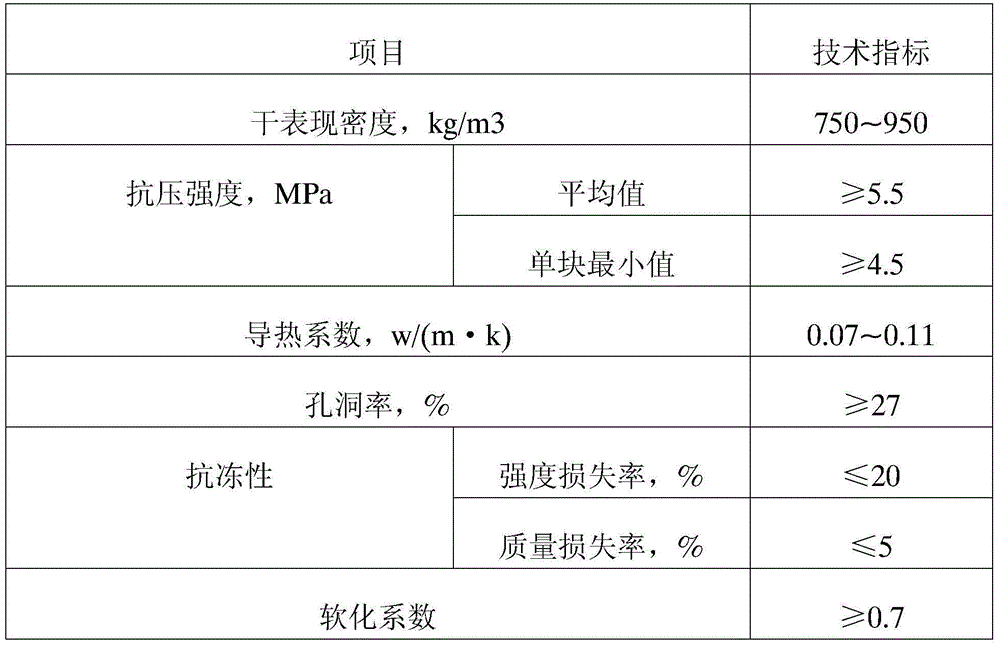

[0033] The following is the product test data

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com