Method for synthesizing monolayer manganese dioxide nanosheet by one step

A technology of manganese dioxide and nanosheets, applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, nanotechnology, etc., can solve the problem of lack of capacitance properties of single-layer manganese dioxide, it is difficult to obtain single-layer manganese dioxide nanosheets, Measured value is small and other problems, to achieve excellent oxidation-reduction performance, promote diffusion and electron transfer, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

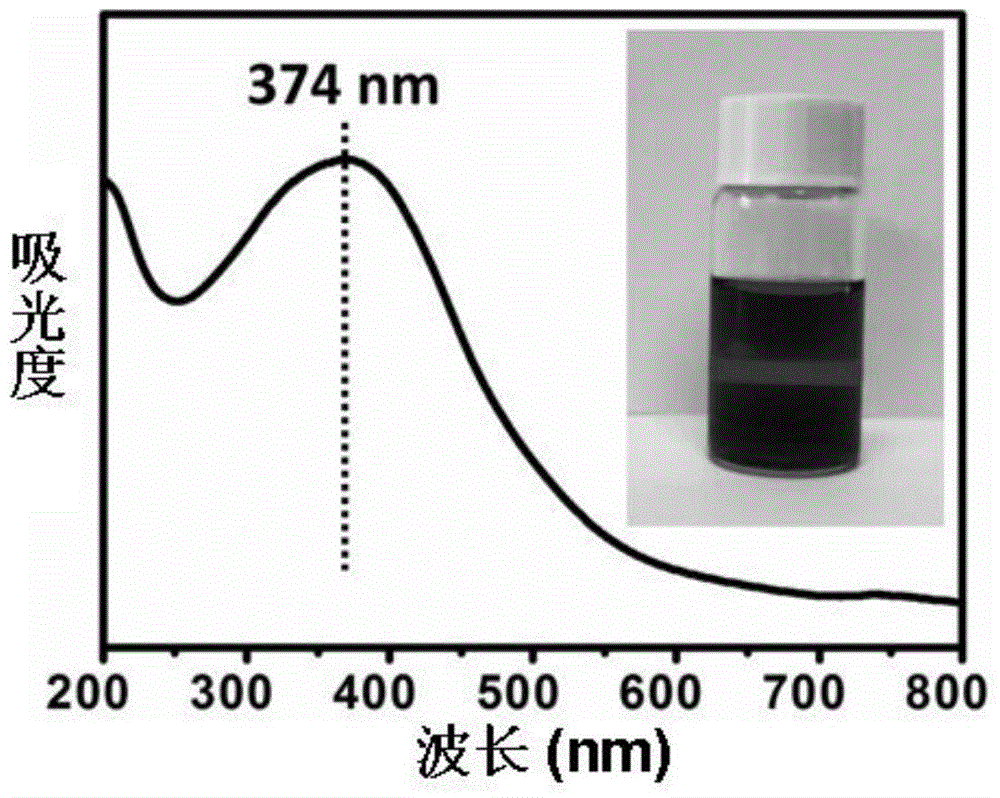

[0024] Dissolve 3.20 mmol of sodium lauryl sulfate in 300 mL of deionized water, and adjust the pH of the solution to 3 with sulfuric acid. The mixed solution was heated at 95° C. for 15 minutes, then 3.2 mL of potassium permanganate aqueous solution with a concentration of 50 mM was added, and the heating was continued at 95° C. for 1 hour to obtain a tan single-layer manganese dioxide nanosheet colloidal solution.

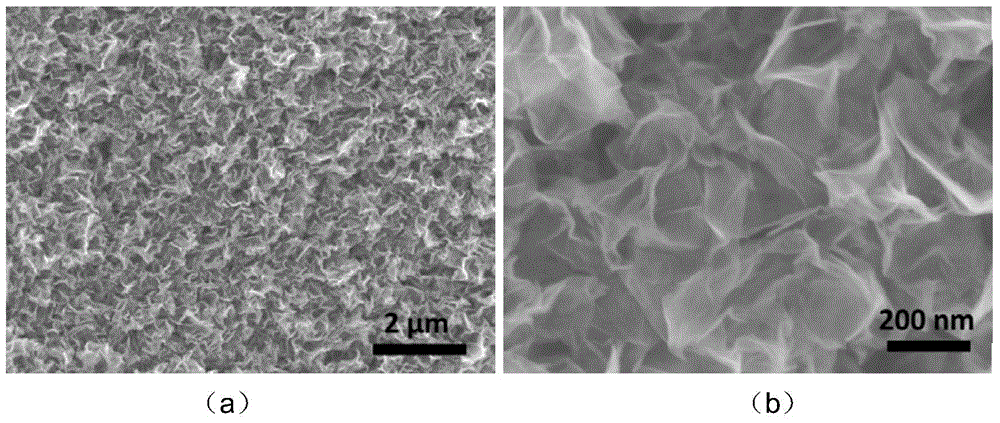

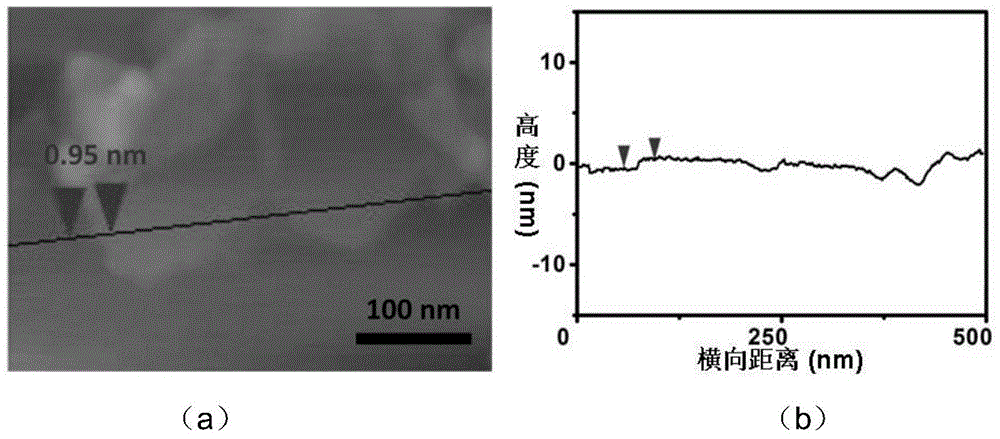

[0025] After centrifuging the prepared single-layer manganese dioxide nanosheet colloidal solution at a speed of 14000 rpm for 10 minutes, the lower layer of precipitate was removed, and the precipitate was repeatedly washed with ethanol and deionized water for three times to purify the sample. The purified sample was freeze-dried at -50°C for 10 hours to obtain a single-layer manganese dioxide nanosheet solid. The nanosheets have a thickness of 0.95nm and an average width of 200nm.

[0026] Embodiment 1 performance test

[0027]Mix the single-layer manganese d...

Embodiment 2

[0034] Dissolve 0.16 mmol of sodium lauryl sulfate in 300 mL of deionized water, and adjust the pH of the solution to 3 with sulfuric acid. The mixed solution was heated at 95° C. for 30 minutes, then 3.2 mL of potassium permanganate aqueous solution with a concentration of 50 mM was added, and the heating was continued at 95° C. for 3 hours to obtain a tan single-layer manganese dioxide nanosheet colloidal solution.

[0035] After centrifuging the prepared single-layer manganese dioxide nanosheet colloidal solution at a speed of 14000 rpm for 10 minutes, the lower layer of precipitate was removed, and the precipitate was repeatedly washed with ethanol and deionized water for three times to purify the sample. The purified sample was freeze-dried at -50°C for 5 hours to obtain a single-layer manganese dioxide nanosheet solid. The nanosheets have a thickness of 0.9nm and an average width of 500nm.

Embodiment 3

[0037] Dissolve 1.60 mmol of sodium lauryl sulfate in 300 mL of deionized water, and adjust the pH of the solution to 2 with sulfuric acid. The mixed solution was heated at 95° C. for 15 minutes, then 3.2 mL of potassium permanganate aqueous solution with a concentration of 50 mM was added, and the heating was continued at 95° C. for 1 hour to obtain a tan single-layer manganese dioxide nanosheet colloidal solution.

[0038] After centrifuging the prepared single-layer manganese dioxide nanosheet colloidal solution at a speed of 14000 rpm for 10 minutes, the lower layer of precipitate was removed, and the precipitate was repeatedly washed with ethanol and deionized water for three times to purify the sample. The purified sample was freeze-dried at -50°C for 10 hours to obtain a single-layer manganese dioxide nanosheet solid. The nanosheets have a thickness of 0.7nm and an average width of 150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com