Reaction heat comprehensive utilization system and reaction heat comprehensive utilization method in coproduction of potassium nitrate and ammonium chloride

A technology of potassium nitrate and ammonium chloride, applied in ammonium chloride, chemical instruments and methods, ammonium halide, etc., can solve the problems of low thermal efficiency, unfavorable energy saving and consumption reduction, etc., achieve short residence time, save steam consumption, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

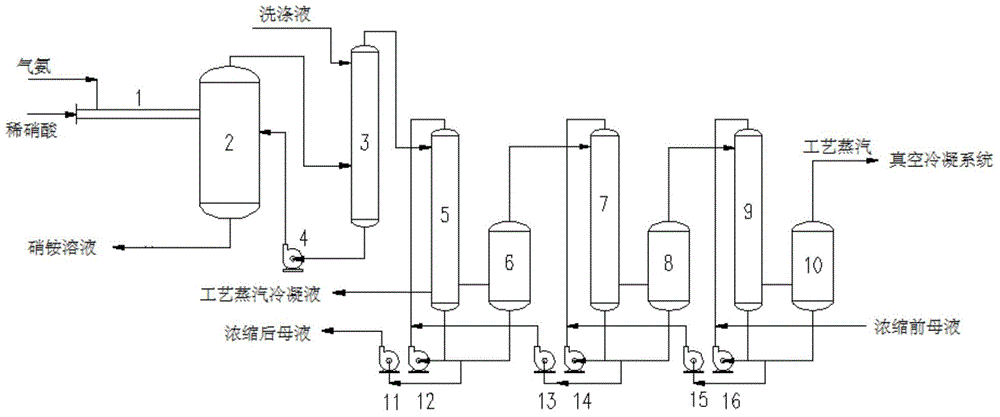

[0030] Such as figure 1 As shown, a system for comprehensive utilization of reaction heat in the production of potassium nitrate co-production ammonium chloride includes a tubular reactor 1, a flash tank 2, a neutralization washing tower 3, a neutralization washing pump 4, and a countercurrent three-effect concentration device; Wherein, the tubular reactor 1 is connected with the flash tank 2, and there is a pipe above the flash tank 2 to communicate with the middle part of the neutralization washing tower 3, and the neutralization washing tower 3 is connected to the flash tank 2 through the neutralization washing pump 4, and the neutralization The top of the washing tower 4 is connected to the steam inlet of the upper part of the first-effect heater 5 in the countercurrent three-effect concentration device through a pipeline;

[0031] The countercurrent three-effect concentrating device comprises three sets of concentrating devices connected in series, one effect concentratin...

Embodiment 2

[0034] A method for comprehensive utilization of reaction heat in potassium nitrate co-production ammonium chloride production, comprising the steps of:

[0035] (1) gaseous ammonia carries out pressurized neutralization reaction with 56wt% dilute nitric acid in tubular reactor 1, and pressure is 0.5MPa, and the molar ratio of control gaseous ammonia and dilute nitric acid is 1~3: 1; Reaction liquid enters flash evaporation Tank 2, use the heat of reaction to carry out flash distillation and concentration to obtain an ammonium nitrate solution with a concentration of 85% to 98%;

[0036] (2) The ammonium nitrate solution obtained above is mixed with the mother liquor of potassium nitrate to obtain the mother liquor before concentration. The addition of the ammonium nitrate solution is added to the mixed solution until the ammonium chloride reaches saturation. After preheating, it enters the countercurrent three-effect concentration device; described potassium nitrate mother li...

Embodiment 3

[0039] A method for comprehensive utilization of reaction heat in potassium nitrate co-production ammonium chloride production, comprising the steps of:

[0040] (1) Gas ammonia is neutralized with 62wt% dilute nitric acid in tubular reactor 1 under pressure at 0.4MPa, and the molar ratio of gas ammonia and dilute nitric acid is controlled to be 0.8-1:1; the reaction liquid enters flash evaporation Tank 2, use the heat of reaction to carry out flash distillation and concentration to obtain an ammonium nitrate solution with a concentration of 85% to 98%;

[0041] (2) The ammonium nitrate solution obtained above is mixed with the mother liquor of potassium nitrate to obtain the mother liquor before concentration. The addition of the ammonium nitrate solution is added to the mixed solution until the ammonium chloride reaches saturation. After preheating, it enters the countercurrent three-effect concentration device; described potassium nitrate mother liquor refers to the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com