Wet concrete recycling and screening machine with automatic sewage pumping and transporting function and application method thereof

A sieving machine and sieving technology, applied in packaging, solid waste removal, etc., can solve the problems of high power consumption, difficult separation of sewage and sand, manual cleaning of car wash tanks and screens, etc., and achieve the effect of smooth stone removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

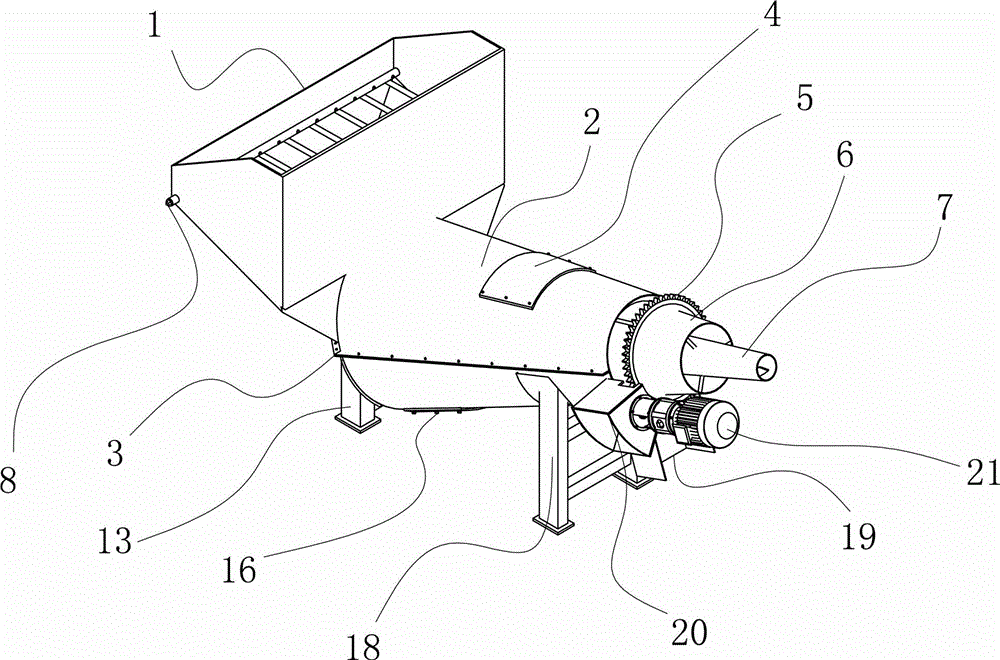

[0099] A sewage automatic pumping and wet concrete recycling and screening machine, such as Figure 1-13 As shown, it includes screening feeding device, sewage screening and conveying device, stone screening and conveying device, sand material screening and conveying device, and screening driving device;

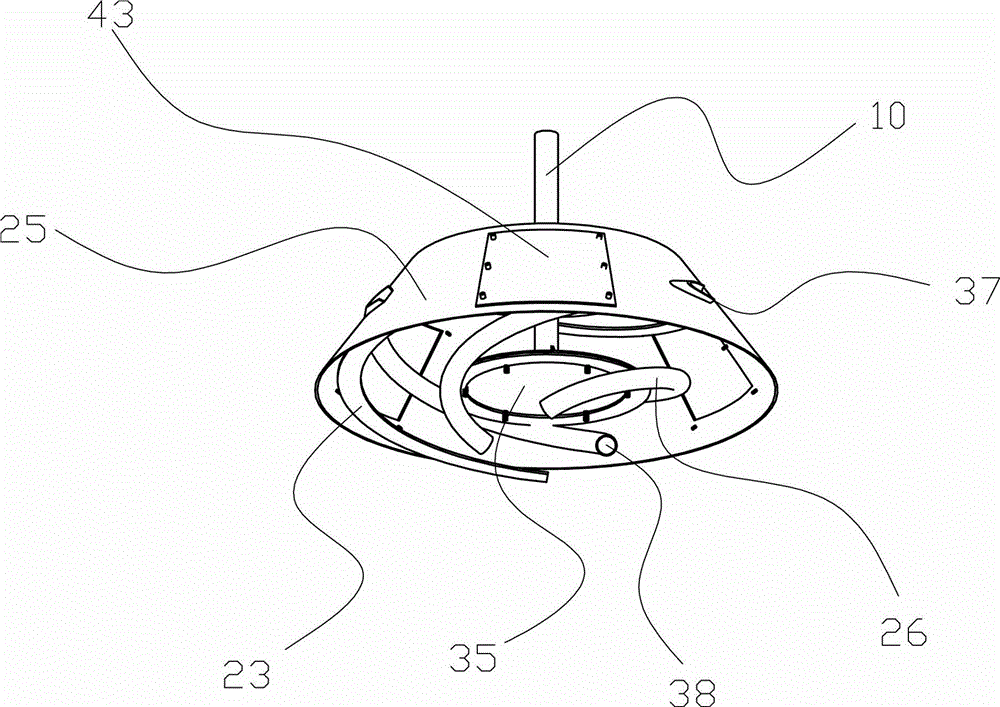

[0100]The screening and feeding device includes a car washing tank 1, a wet concrete flexible conveying screw casing 11, a sealing plate at the end of the casing 12, a screening machine tail casing 15, a shaft end 9, a main shaft 10, a wet concrete flexible conveying screw blade 24, and a screening machine connection. Material pipe shell 25, material receiving and conveying screw blade 23;

[0101] Wet concrete flexible conveying spiral casing 11 is connected to the sealing plate 12 at the end of the casing;

[0102] The car washing tank 1 is connected to the wet concrete flexible conveying screw casing 11, and the wet concrete flexible conveying spiral casing 11 is connect...

Embodiment 2

[0117] A sewage automatic pumping and wet concrete recycling and screening machine, such as Figure 1-13 As shown, it includes screening feeding device, sewage screening and conveying device, stone screening and conveying device, sand material screening and conveying device, and screening driving device;

[0118] The screening and feeding device includes a car washing tank 1, a wet concrete flexible conveying screw casing 11, a sealing plate at the end of the casing 12, a screening machine tail casing 15, a shaft end 9, a main shaft 10, a wet concrete flexible conveying screw blade 24, and a screening machine connection. Material pipe shell 25, material receiving and conveying screw blade 23;

[0119] Wet concrete flexible conveying spiral casing 11 is connected to the sealing plate 12 at the end of the casing;

[0120] The car washing tank 1 is connected to the wet concrete flexible conveying screw casing 11, and the wet concrete flexible conveying spiral casing 11 is connec...

Embodiment 3

[0140] A method of using a sewage automatic pumping wet concrete recycling and screening machine, such as Figure 1-13 shown, including the following steps:

[0141] a. Feeding: After adding wet concrete and sewage for washing the wet concrete into the car washing tank 1, the wet concrete will automatically gather at the bottom of the car washing tank 1, and the sewage will enter the screening machine. The bottom of the car washing tank 1 is higher than the bottom of the screening machine. After the sewage in the screening machine exceeds the height of 500mm, it is the same as the water level at the bottom of the car wash tank 1, and the sewage floods the wet concrete in the car wash tank 1;

[0142] b. Pre-mixing conveying: Wet concrete flexible conveying by screw, wet concrete flexible conveying screw blade 24 has a small diameter on the bottom surface and a large diameter on the top surface, and the material is transported upwards with an inclination. The discharge port is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com