On-line clearing method of dilute acid pipe scales in phosphate ore magnesium-removing and ore-dressing production

A technology of phosphate rock and dilute acid, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of laborious and time-consuming manual cleaning of dilute acid pipelines, and achieve obvious and flexible descaling Flexible, no-investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

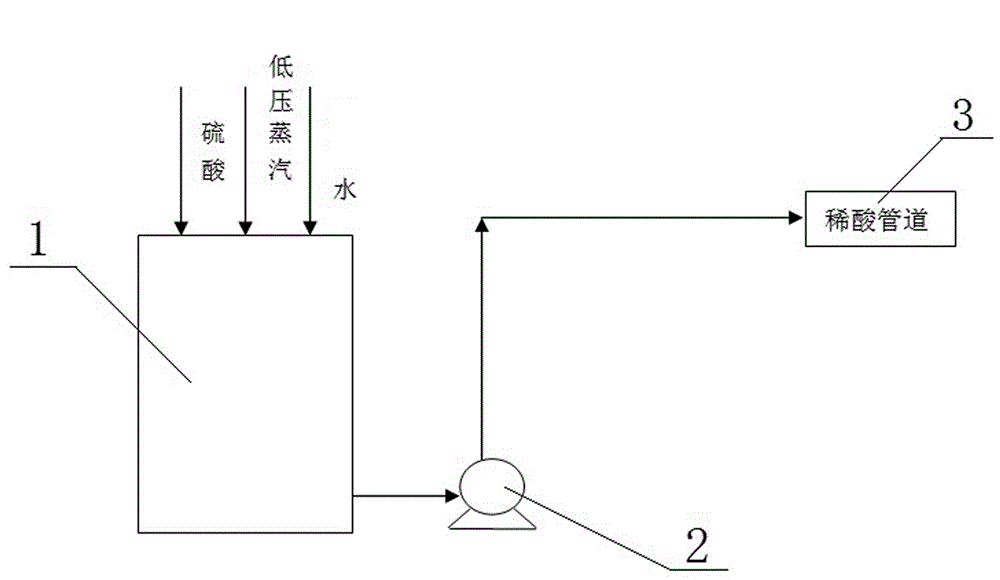

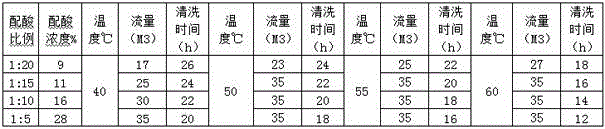

[0015] An on-line cleaning method for dilute acid pipeline scaling in the production of phosphate rock for magnesium removal ore dressing. The dilute acid configuration tank 1 is equipped with a cleaning solution composed of sulfuric acid and water with a mass fraction of 98%. The volume ratio of sulfuric acid to water is The ratio is 1:5; then the low-pressure steam with a pressure of 0.3 Mpa is introduced into the dilute acid configuration tank 1 for heating, and the heating temperature is 40°C; the heated cleaning solution is sent into the dilute acid configuration tank 1 with the delivery pump 2 The acid pipeline 3 is cleaned, and the cleaning time is 20 h.

Embodiment 2

[0017] An on-line cleaning method for dilute acid pipeline scaling in the production of phosphate rock for magnesium removal ore dressing. The dilute acid configuration tank 1 is equipped with a cleaning solution composed of sulfuric acid and water with a mass fraction of 98%. The volume ratio of sulfuric acid to water is The ratio is 1:15; then the low-pressure steam with a pressure of 0.4 Mpa is introduced into the dilute acid configuration tank 1 for heating, and the heating temperature is 50°C; the heated cleaning solution is sent into the dilute acid configuration tank 1 with the delivery pump 2 The acid pipeline 3 is cleaned, and the cleaning time is 22 h.

Embodiment 3

[0019] An on-line cleaning method for dilute acid pipeline scaling in the production of phosphate rock for magnesium removal ore dressing. The dilute acid configuration tank 1 is equipped with a cleaning solution composed of sulfuric acid and water with a mass fraction of 98%. The volume ratio of sulfuric acid to water is The ratio is 1:20; then the low-pressure steam with a pressure of 0.5 Mpa is introduced into the dilute acid configuration tank 1 for heating, and the heating temperature is 60°C; the heated cleaning solution is sent into the dilute acid configuration tank 1 with the delivery pump 2 The acid pipeline 3 is cleaned, and the cleaning time is 18 h.

[0020] Gansu Wengfu Chemical Co., Ltd. Mineral Concentration Plant has 800,000 tons / year phosphorous concentrate flotation production. Before this method is used for cleaning, the dilute acid pipeline flow rate can only reach 15M 3 / h, the statistics of the cleaning effect after adopting this method for the dilute ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com