Self-dehydration hydrophobic separation membrane and preparation method

A separation membrane, hydrophobic technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of difficult engineering implementation method, uneven drying degree, difficult engineering application, etc., to reduce separation The effect of mass transfer resistance, large contact angle and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

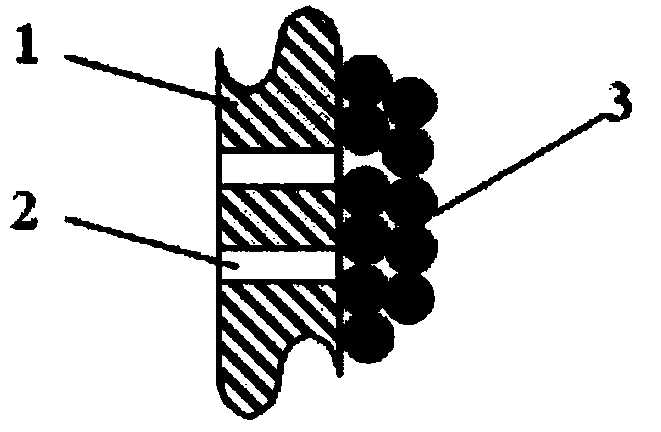

[0036] 100 grams of polyvinylidene fluoride particles (attached figure 1 3 in 3, particle size 2 ~ 5μm, Sanaifu company, brand F904), stirring and dispersing in 2000 grams of dispersant absolute ethanol, to obtain polyvinylidene fluoride particle suspension; Aperture (attached figure 1 In 2) a hydrophilic polyvinylidene fluoride porous membrane of 0.2 μm (attached figure 1 1) in the outer surface. The hydrophilic polyvinylidene fluoride porous membrane coated with the polyvinylidene fluoride particle suspension was taken out from the ultrafiltration coating device, dried in air at room temperature, and then placed in an oven at 85°C for 4 hours to make The outer surface of the hydrophilic polyvinylidene fluoride porous membrane forms a hydrophobic polyvinylidene fluoride particle separation membrane layer with a micro-nano concave-convex structure. The thickness of the hydrophobic polyvinylidene fluoride particle separation membrane layer is 20 μm, and the pore size of the s...

Embodiment 2

[0039] 60 grams of polyvinylidene fluoride particles (particle size 80 ~ 100nm, self-made), stirred and dispersed in a mixed solvent of 1000 grams of dispersant acetone and 400 grams of ethyl acetate to obtain a suspension of polyvinylidene fluoride particles; then ultrafiltration coating It is coated on the outer surface of a hydrophilic polyvinylidene fluoride porous membrane with a thickness of 200 μm and a pore size of 0.2 μm. The hydrophilic polyvinylidene fluoride porous membrane coated with the polyvinylidene fluoride particle suspension is taken out from the ultrafiltration coating device, and dried in air at room temperature, so that the outer surface of the hydrophilic polyvinylidene fluoride porous membrane forms Hydrophobic polyvinylidene fluoride particle separation membrane layer with micro-nano concave-convex structure, the thickness of the hydrophobic polyvinylidene fluoride particle separation membrane layer is 20 μm, the pore size of the separation membrane is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com