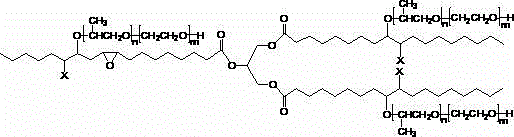

Vegetable oil modified defoaming agent and preparation method thereof

A technology of vegetable oil modification and defoaming agent, applied in the direction of foam dispersion/prevention, etc., can solve the problems of poor hydrophilicity, easy deterioration and difficult dispersion, etc., and achieve the effects of improving dispersibility, reducing dosage and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

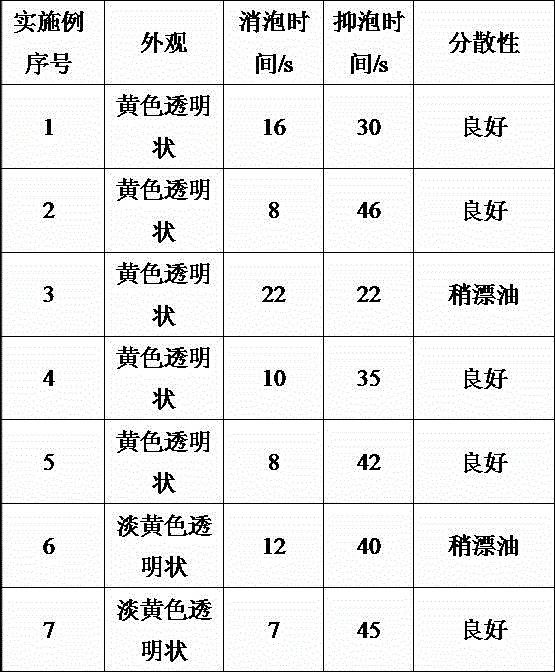

Examples

Embodiment 1

[0024] Embodiment 1: Prepare vegetable oil modified defoamer according to the following steps

[0025] (1) Add a mixture of 5 kg epoxy soybean oil and isopropanol (the molar ratio of epoxy group to isopropanol in soybean oil is 1.1:5), 10 g fluoroboric acid into the reactor, and stir under nitrogen protection Heating to 100°C, reacting for 2 hours, cooling to room temperature, extracting the reaction mixture with ethyl acetate, then washing the organic layer three times with saturated sodium chloride solution, after liquid separation, the organic layer was distilled under reduced pressure to remove the solvent to obtain soybean oil multi-component alcohol;

[0026] (2) 2 kg soybean oil polyol and 0.26 g Zn 3 [Co(CN) 6 ] 2 0.08ZnCl 2 1.0H 2 Add O 1.5DME into the high-pressure reactor, keep 120°C for dehydration under reduced pressure for 30 min, replace with nitrogen three times during this period, and then put 100 g of propylene oxide to induce the reaction, the ind...

Embodiment 2

[0027] Embodiment 2: prepare vegetable oil modified defoamer according to the following steps

[0028] (1) Add a mixture of 5 kg epoxy soybean oil and isopropanol (the molar ratio of epoxy group to isopropanol in soybean oil is 1:1), 5 g of fluoroboric acid into the reactor, stir and heat under nitrogen protection After reacting for 2 hours at 100°C, cool to room temperature, extract the reaction mixture with ethyl acetate, then wash the organic layer three times with saturated sodium chloride solution, and after separation, the organic layer is distilled under reduced pressure to remove the solvent to obtain soybean oil polyol ;

[0029] (2) 2 kg soybean oil polyol and 0.34 g Zn 3 [Co(CN) 6 ] 2 0.08ZnCl 2 1.0H 2 Add O 1.5DME into the high-pressure reactor, keep 130°C for dehydration under reduced pressure for 30 min, replace with nitrogen three times during this period, and then put 100 g of propylene oxide to induce the reaction. When the pressure drops obviously ...

Embodiment 3

[0030] Embodiment 3: prepare vegetable oil modified defoamer according to the following steps

[0031] (1) Add a mixture of 5 kg epoxy soybean oil and isopropanol (the molar ratio of epoxy group to isopropanol in soybean oil is 1:2) and 8 g fluoroboric acid into the reactor, stir and heat under nitrogen protection After reacting for 2 hours at 100°C, cool to room temperature, extract the reaction mixture with ethyl acetate, then wash the organic layer three times with saturated sodium chloride solution, and after separation, the organic layer is distilled under reduced pressure to remove the solvent to obtain soybean oil polyol ;

[0032] (2) 2 kg soybean oil polyol and 0.52 g Zn 3 [Co(CN) 6 ] 2 0.08ZnCl 2 1.0H 2 Add O·1.5DME into the high-pressure reactor, keep 120°C for dehydration under reduced pressure for 30 min, replace with nitrogen three times during this period, then put in 100 g of propylene oxide to induce the reaction, the induction temperature is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com