Loquat film-coating preservative and preparation method thereof

A film-coated preservative and loquat technology, applied in the field of loquat-coated preservative and its preparation, can solve the problems of poor fresh-keeping effect and single component of loquat-coated preservative, and achieve prolonged fresh-keeping period, film-forming performance and fresh-keeping Good effect and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

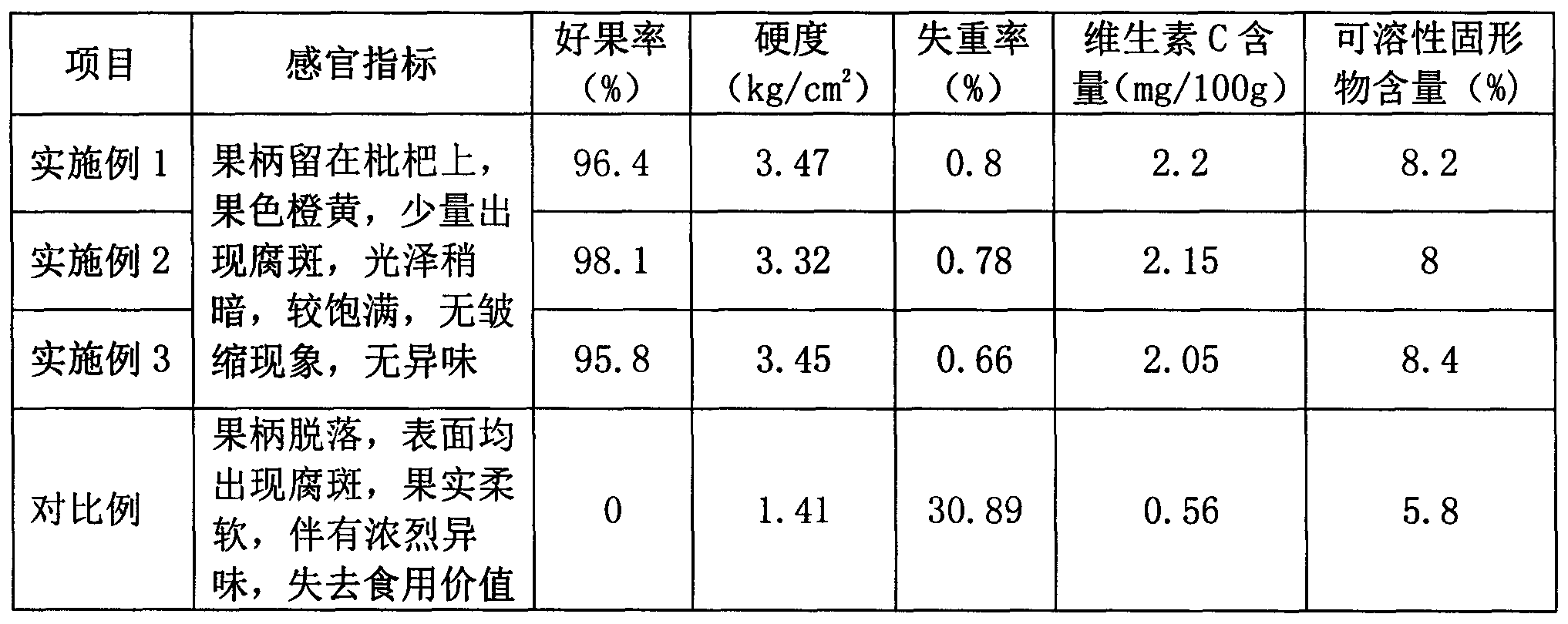

Examples

Embodiment 1

[0023] (1) Preparation of pseudophysalis gum

[0024] Soak the dried pseudophysalis seeds after removal of impurities in water 12 times the mass of dry pseudophysalis seeds for 2 hours, heat and stir at 60°C for 2 hours, filter the extract with 3 layers of gauze, and wrap the filter with gauze Repeatedly kneading and extruding for 5 minutes, then extract once again according to the above conditions, combine the filtrates, concentrate in vacuo at 60°C to 1mL of a concentrated solution containing 1.5g of solid matter, add ethanol for alcohol precipitation after cooling, collect the precipitate, dry it in vacuum at 60°C, and pulverize , that is, pseudophysalis gum, ready to use.

[0025] (2) Preparation of clove extract

[0026] Cloves were crushed and 5 times the amount of water was added, ultrasonically extracted for 1 hour, and the extract was obtained by filtration, and the extraction was repeated twice to combine the extracts to obtain the clove extract, which was ready for...

Embodiment 2

[0032] (1) Preparation of pseudophysalis gum

[0033] Soak the dried pseudophysalis seeds after removal of impurities in water 10 times the mass of dry pseudophysalis seeds for 1 hour, heat and stir at 50°C for 1 hour, filter the extract with 3 layers of gauze, and wrap the filter with gauze Repeatedly kneading and extruding for 3 minutes, then extract once again according to the above conditions, combine the filtrates, concentrate in vacuo at 55°C to 1mL of a concentrated solution containing 1g of solid matter, add ethanol for alcohol precipitation after cooling, collect the precipitate, dry it in vacuum at 55°C, and crush it. That is, the pseudophysalis gum is obtained and is set aside.

[0034] (2) Preparation of clove extract

[0035] After the cloves were crushed, 3 times the amount of water was added, ultrasonically extracted for 0.5 h, the extract was obtained by filtration, and the extraction was repeated twice to combine the extracts to obtain the clove extract, whic...

Embodiment 3

[0041] (1) Preparation of pseudophysalis gum

[0042] Soak the dried pseudophysalis seeds after removal of impurities in water 11 times the mass of dry pseudophysalis seeds for 1.2 hours, heat and stir at 56°C for 1.5 hours, filter the extract with 3 layers of gauze, and filter the filtered product with gauze After wrapping, knead and squeeze repeatedly for 4 minutes, then extract once according to the above conditions, combine the filtrates, concentrate in vacuo at 56°C to 1mL of a concentrated solution containing 1.2g of solids, add ethanol after cooling, and collect the precipitate and dry it in vacuum at 58°C , pulverized, that is, pseudophysalis gum, stand-by.

[0043] (2) Preparation of clove extract

[0044] Cloves were crushed and 4 times the amount of water was added, ultrasonically extracted for 0.7 h, the extract was filtered, and the extraction was repeated twice to combine the extracts to obtain the clove extract, which was ready for use.

[0045] (3) Mixing

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com