Rear plug type case installation rack

A plug-in and mounting frame technology, which is applied in the direction of support structure installation, casing/cabinet/drawer parts, clamping/drawing device, etc., can solve the loss of cooling capacity along the way, heavy weight, and chassis mounting frame Large volume and other problems, to reduce the loss along the way, reduce the overall size and materials, and solve the effect of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

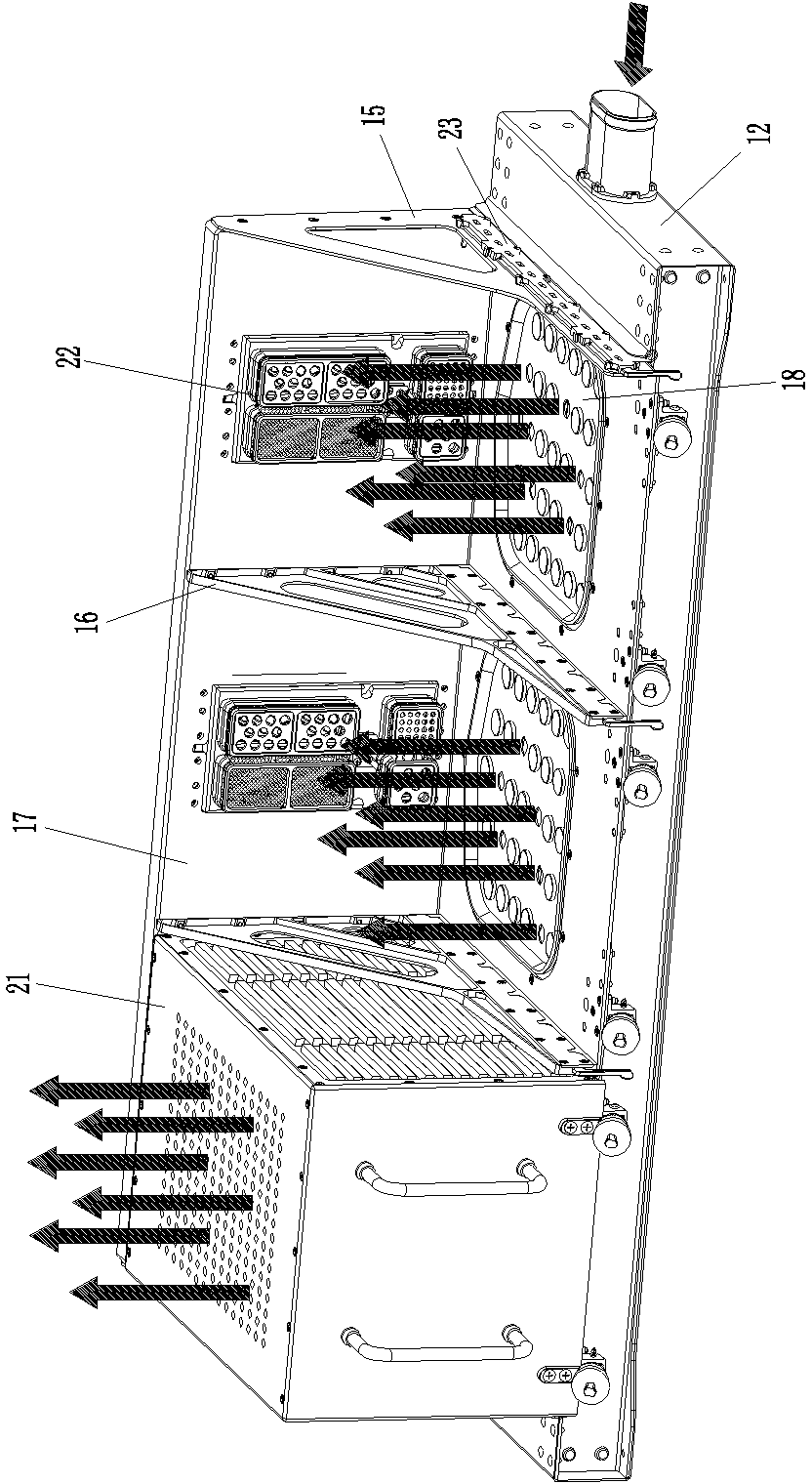

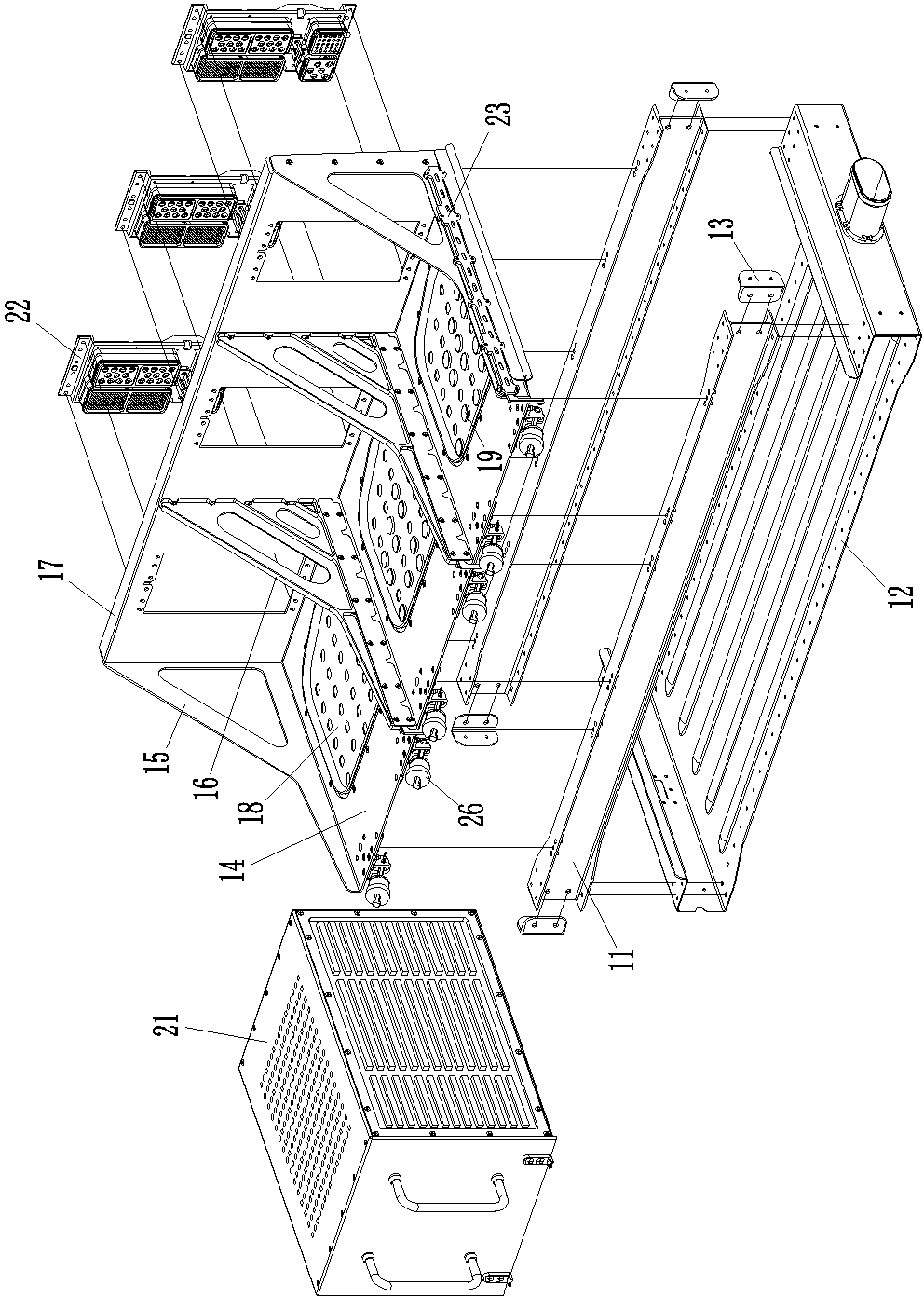

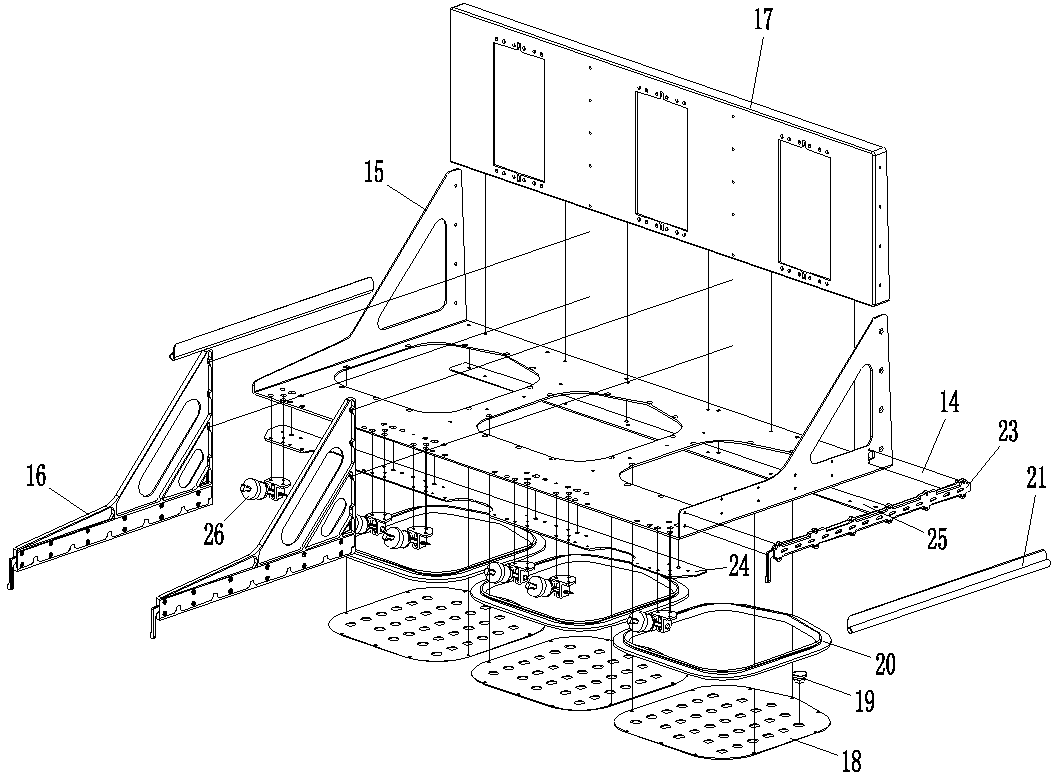

[0015] Examples of rear-swappable chassis mounts, such as Figure 1-3 As shown, the rear plug-in chassis mounting bracket includes a support seat, a guide piece, and a front tightening device.

[0016] The supporting seat includes a load-bearing frame 11 and an air channel plate 12 arranged on the load-bearing frame. The load-bearing frame 11 and the air channel plate 12 together form an air channel structure. Specifically, there are two beams and they are arranged in parallel. The air channel plate 12 includes a substantially U-shaped bottom plate located at the lower part. At the same time, the surrounding wall on the corresponding side of the air duct is formed, so that the load-bearing frame 11 and the air duct plate 12 together form a groove structure with only an upper side opening. In this embodiment, three chassis installation positions are arranged side by side along the left and right directions on the supporting seat with the above structure. Of course, in other em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com