Touch panel and display screen integrated OLED display device

A touch panel and display device technology, applied in the field of OLED display devices, can solve problems such as reducing visible light transmittance, increasing the number of parts, and affecting device costs, so as to save the bonding process, reduce the bonding layer, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and the method for preparing the packaging cover plate provided with the touch function layer, which is an explanation of the present invention rather than a limitation.

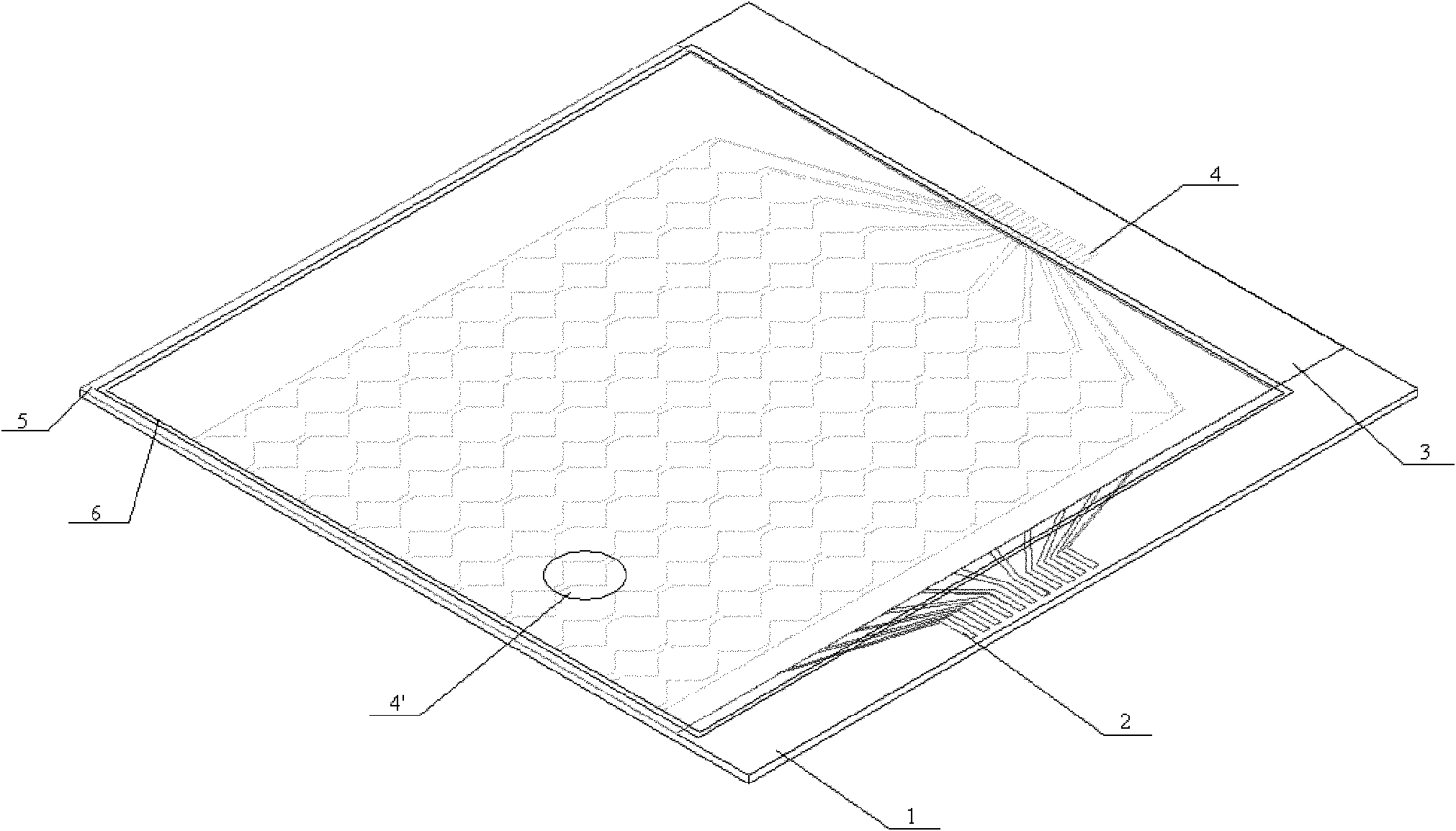

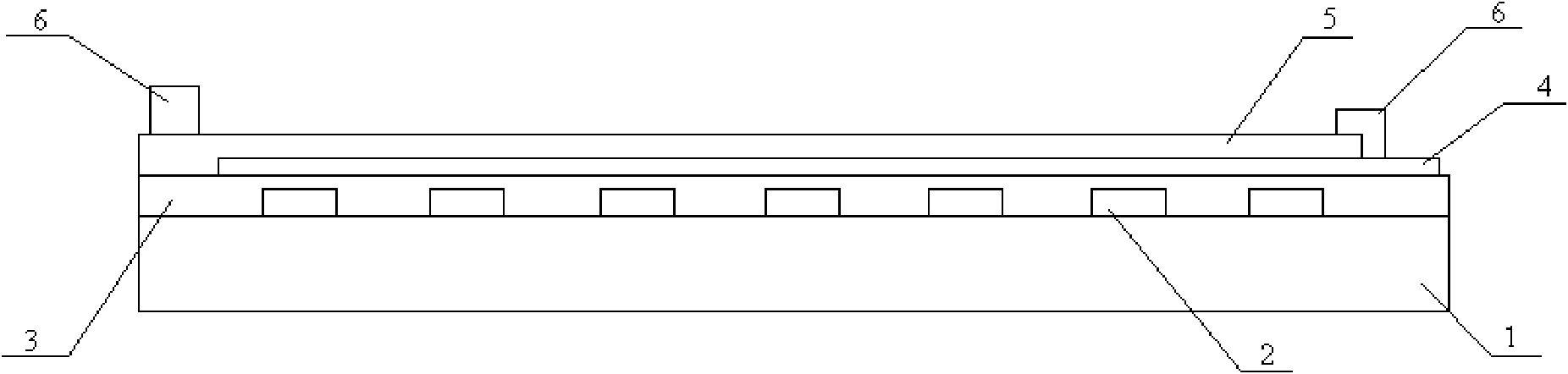

[0025] see Figure 1 to Figure 4 , an OLED display device in which a touch panel is integrated with a display screen, comprising an anode substrate 7 and a packaging cover 1 bonded through a sealing frame 6, and a gate 8 sequentially arranged between the anode substrate 7 and the packaging cover 1 , gate insulating layer 9, source electrode 10, hole injection layer 11, hole transport layer 12, electron blocking layer 13, light emitting layer 14, hole blocking layer 15, electron transport layer 16, electron injection layer 17; light emitting layer The light emitted by 14 is emitted through one side of the packaging cover 1 and reaches the user's eyes.

[0026] In the present invention, a touch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com