Gas chromatograph for analyzing trace impurities in electronic grade hexafluoroethane

A gas chromatograph and hexafluoroethane technology, which is applied in the field of gas chromatograph used for the analysis of trace impurities in electronic grade hexafluoroethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

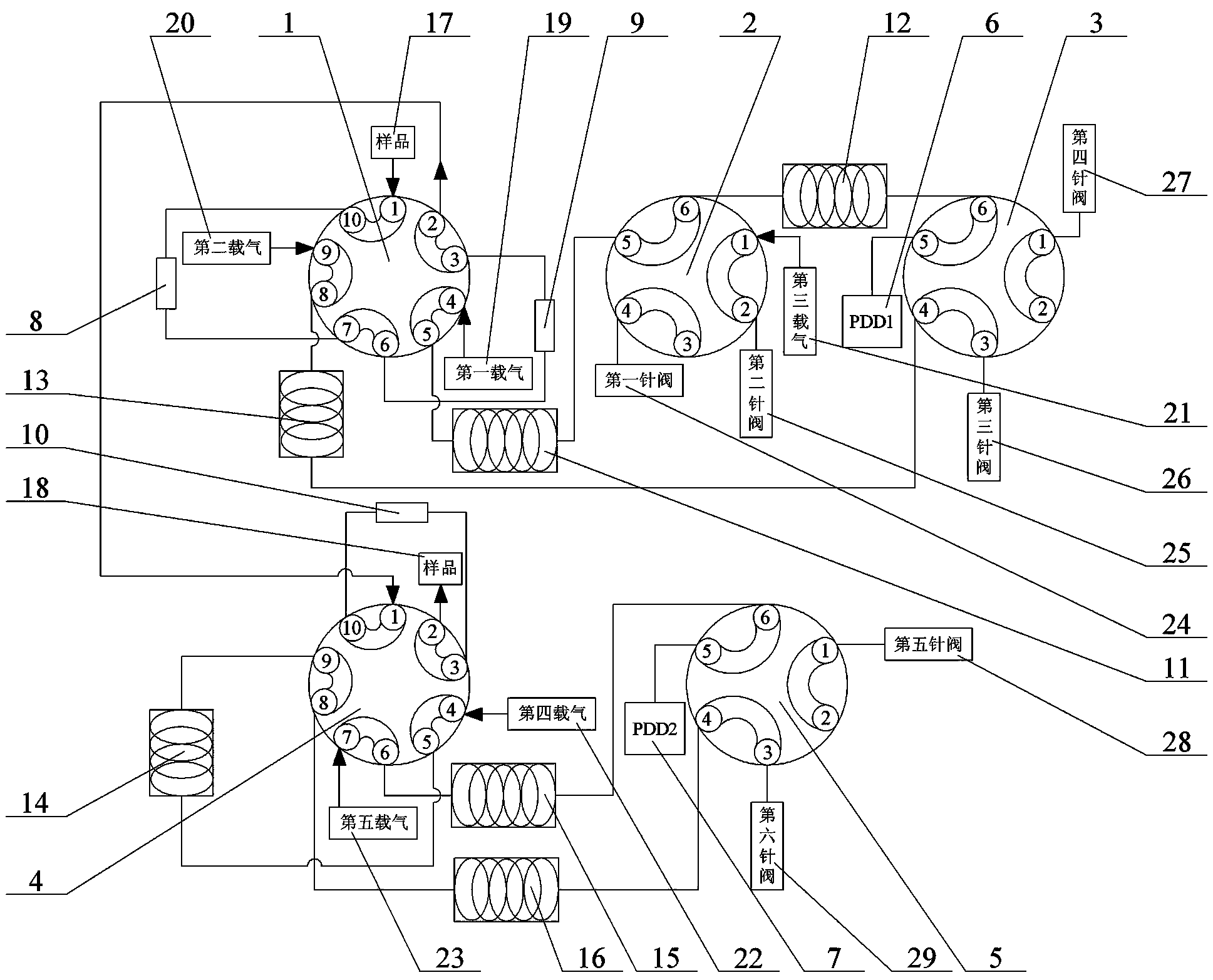

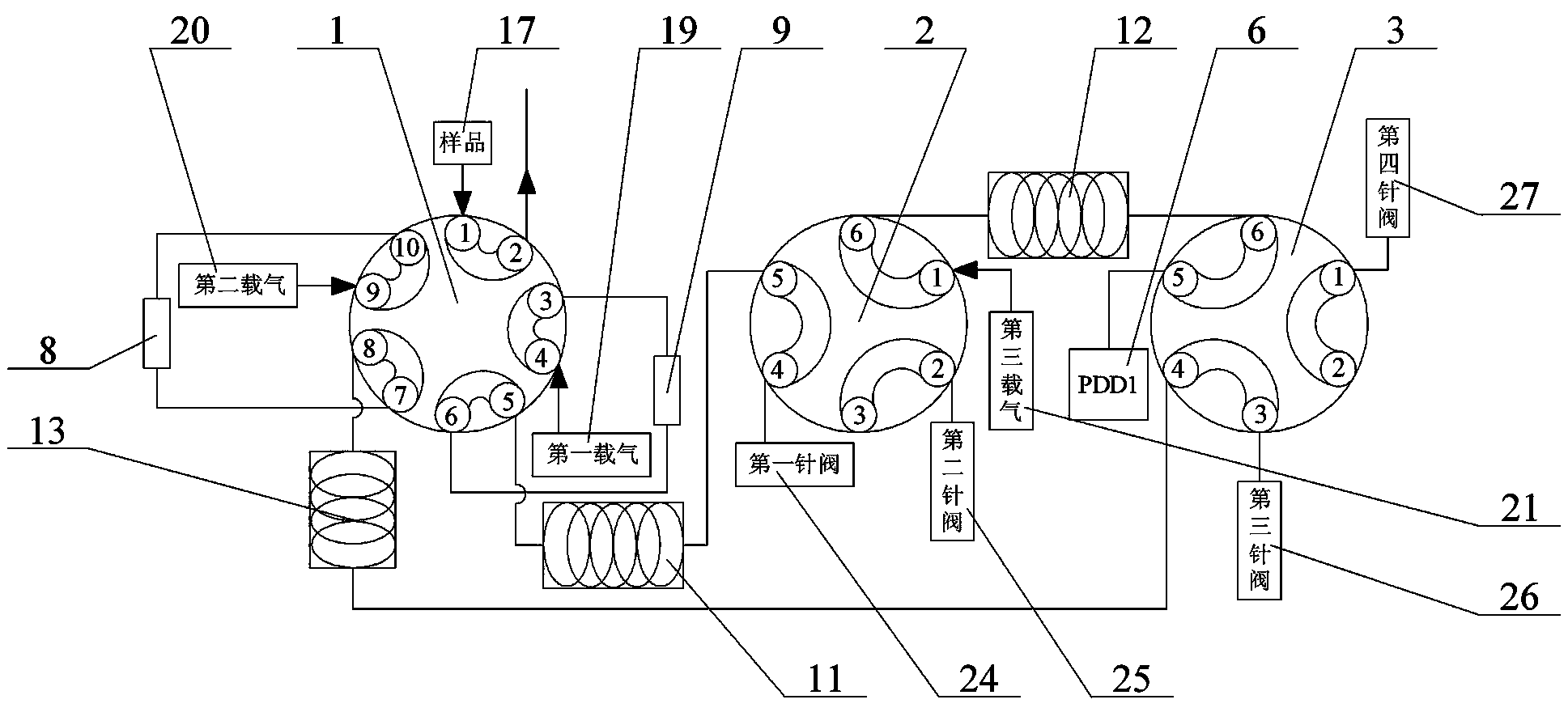

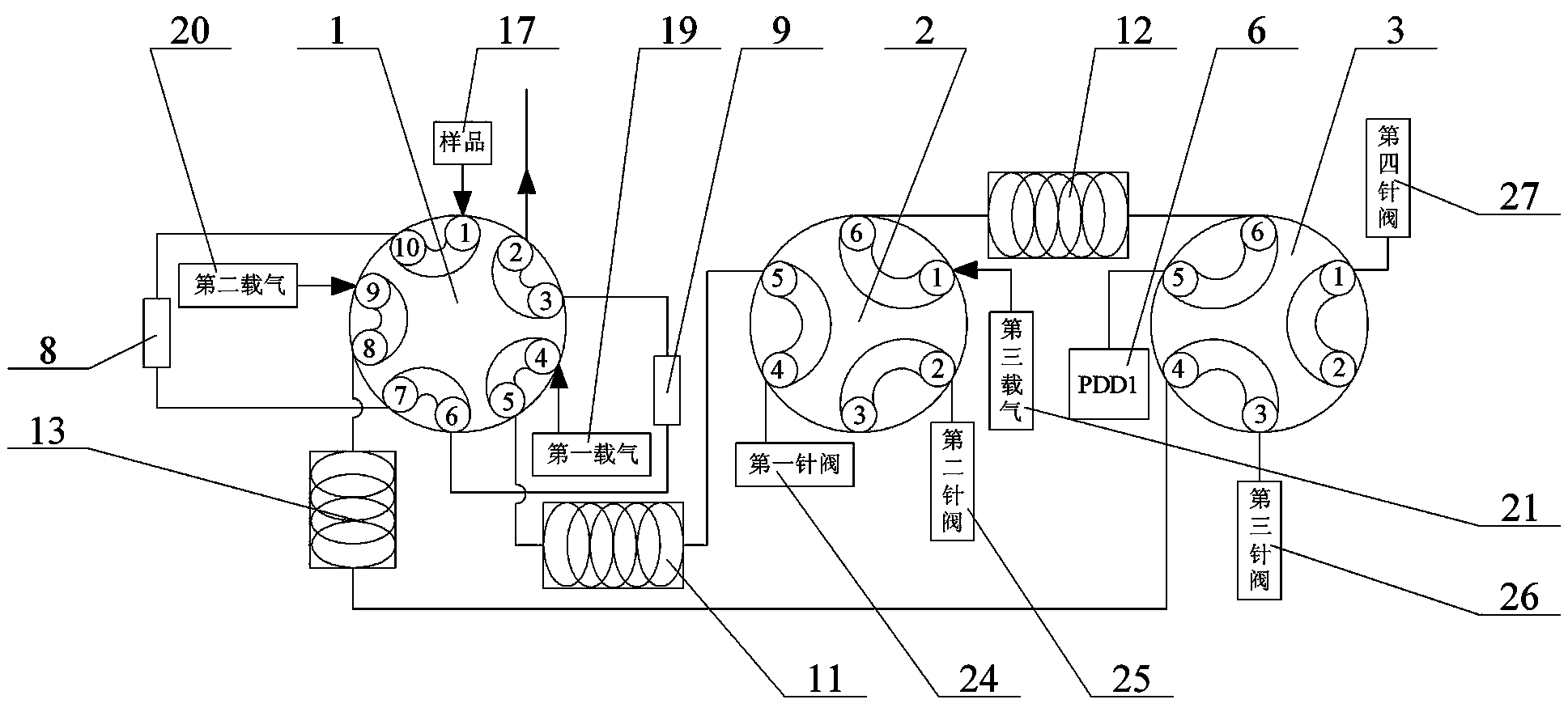

[0026] as attached figure 1 As shown, the gas chromatograph used for the analysis of trace impurities in electronic grade hexafluoroethane of the present invention has a structure including a sampling system, a switching valve, a chromatographic column, a venting needle valve and a detector. The first switching valve 1 is provided with a first quantitative tube 8 and the second quantitative tube 9, the second switching valve 2 is provided with a first needle valve 24 and a second needle valve 25, and the third switching valve 3 is provided with a first Three needle valve 26, the fourth needle valve 27 and the first detector PDD16, the fourth switching valve 4 is provided with the fourth chromatographic column 14 and the third quantitative tube 10, the fifth switching valve 5 is provided with the fifth needle valve 28. The sixth needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com