Production method of aluminum alloy plate for coal gondola car

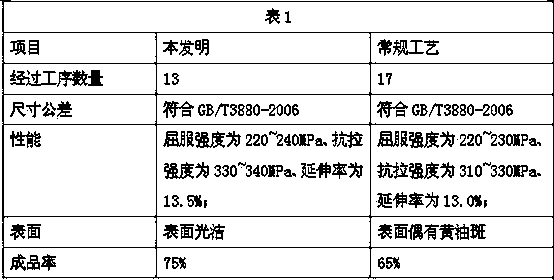

A technology of an aluminum alloy sheet and a manufacturing method, which is applied in the field of aluminum alloy materials, can solve the problems of low production efficiency, long production process, butter stains on the board surface, etc., and achieves the effects of high production efficiency, good surface quality and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking the production of the 5083H321 state aluminum alloy plate whose finished product specification is thickness 6.0 mm*width 2420 mm*length 10612 mm as an example, the manufacturing method of a kind of aluminum alloy plate for coal transport gondola of the present invention is illustrated, comprising the following steps:

[0038] (1) Ingredients: The chemical composition is mixed according to the following weight percentages, that is, Si≤0.2%, Fe≤0.3%, Cu≤0.1%, 0.6%≤Mn≤0.8%, 4.5%≤Mg≤4.8%, 0.15%≤Cr ≤0.2%, 0.05%≤Zn≤0.1%, 0.1%≤Ti≤0.15%, 0.1%≤Sc≤0.15%, 0.1%≤Zr≤0.15%, the balance is Al;

[0039] (2) Melting: the melting temperature is 700~740°C;

[0040] (3) Refining: use "chlorine + argon" to refine the melt, and the refining temperature is 730~740°C;

[0041] (4) Grain refinement: Use grain refiner Al-5Ti-0.2B wire to conduct online grain refinement on the melt;

[0042] (5) Degassing: The Alpur method degassing device is used to degas the melt online;

[0043] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com