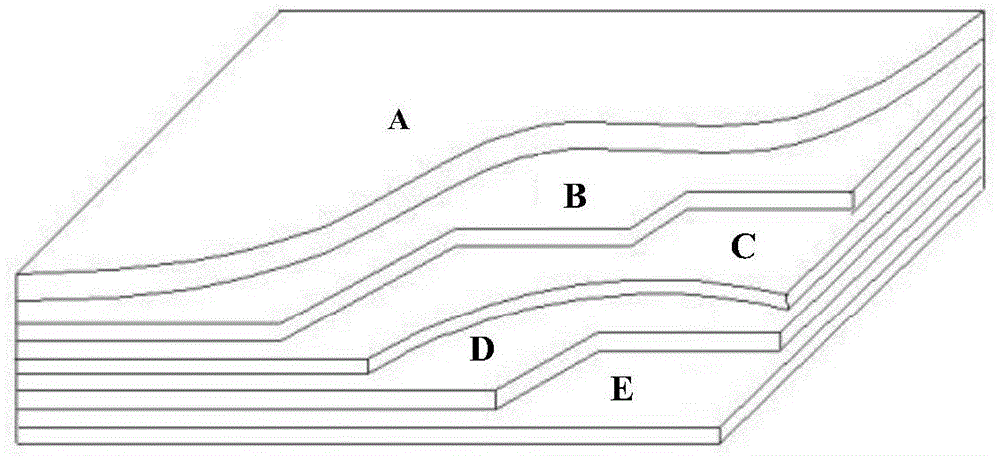

Luminous epoxy coiled material and preparation method thereof

A luminous epoxy coil and epoxy resin technology, applied in the direction of epoxy resin glue, epoxy resin coating, chemical instruments and methods, etc., can solve the problems of short service life, environmental pollution, and inconvenient construction of luminescent coatings, and achieve Stable luminescent performance, stable chemical properties, and good cured cross-linking regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] First, prepare four components A, B, C and D respectively, the steps are:

[0080] (1) Preparation of component A

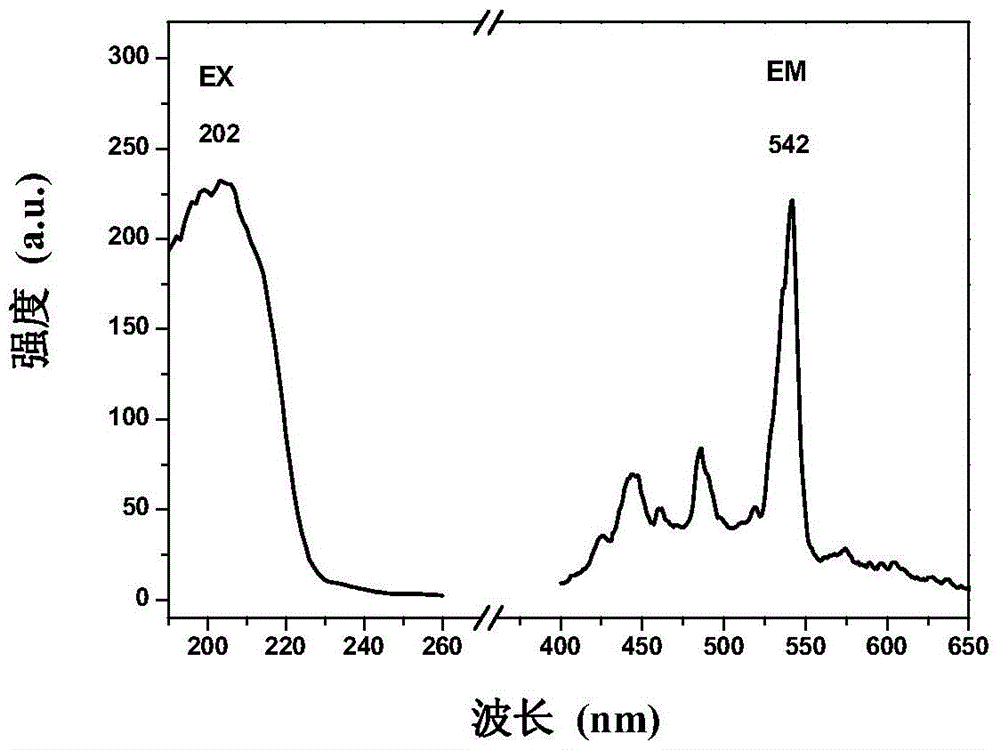

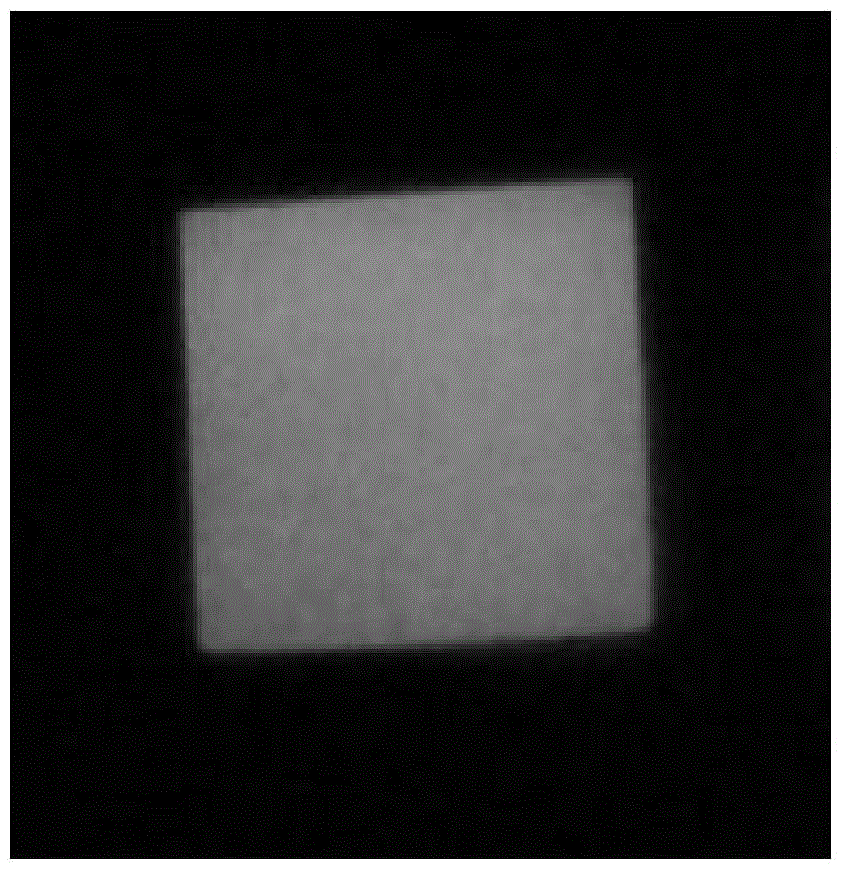

[0081] 54% by weight of nano-modified epoxy resin, 5% of KYD-4F2 type yellow-green light long afterglow luminescent material, 23.5% of resol type phenolic resin (number average molecular weight 460, solid content 75%), 4% of Toughness agent EP-2000, 7.5% diluent BGE, 0.3% leveling agent EFKA-3239, 0.3% defoamer EFKA-2720, 2.5% flame retardant magnesium hydroxide, 3% anti-scratch agent poly Mix methylsiloxane and 3.5% quartz powder evenly, and filter to obtain component A.

[0082] (2) Preparation of component B

[0083] 99% by weight of T31 curing agent and 1% by weight of 2,4,6-tris(dimethylaminomethyl)phenol were uniformly mixed to obtain component B.

[0084] (3) Preparation of component C

[0085] The high molecular weight epoxy resin E-03 (number average molecular weight is 6000) that is 15% by weight percentage, the low molecular weight epoxy res...

Embodiment 2

[0100] First, prepare four components A, B, C and D respectively, the steps are:

[0101] (1) Preparation of component A

[0102]65% by weight of nano-modified epoxy resin, 15% of KYD-4F2 type yellow-green long-lasting luminescent material, 6% of resol type phenolic resin (number average molecular weight 460, solid content 75%), 3% of Toughener EP-2000, 5.6% diluent BGE, 0.2% leveling agent EFKA-3239, 0.2% defoamer EFKA-2720, 3.5% flame retardant magnesium hydroxide and, 1.5% anti-scratch agent poly Mix dimethylsiloxane and 2.5% quartz powder evenly, and filter to obtain component A.

[0103] (2) Preparation of component B

[0104] 99% by weight of T31 curing agent and 1% by weight of 2,4,6-tris(dimethylaminomethyl)phenol were uniformly mixed to obtain component B.

[0105] (3) Preparation of component C

[0106] The high molecular weight epoxy resin E-03 (number average molecular weight is 6000), the low molecular weight epoxy resin E51 (number average molecular weight is...

Embodiment 3

[0116] First, prepare four components A, B, C and D respectively, the steps are:

[0117] (1) Preparation of component A

[0118] The weight percent is 60% nano-modified epoxy resin, 10% KYD-10 type sky blue light long afterglow luminescent material, 10.5% resol type phenolic resin (number average molecular weight 460, solid content 75%), 5% Toughener D-410, 8% thinner 692, 0.3% leveling agent BYK-307, 0.2% defoamer EFKA-2720, 2.5% flame retardant magnesium hydroxide, 3% anti-scratch agent poly Mix dimethylsiloxane and 10% quartz powder evenly, and filter to obtain component A.

[0119] (2) Preparation of component B

[0120] 97% by weight of T31 curing agent and 3% by weight of 2,4,6-tris(dimethylaminomethyl)phenol were uniformly mixed to obtain component B.

[0121] (3) Preparation of component C

[0122] Be 12% high molecular weight epoxy resin E-03 (number average molecular weight is 6000), 35% low molecular weight epoxy resin E51 (number average molecular weight is 39...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com