Method of nano halogen-free flame retardant polyamide-6

A technology for flame retardant polyamide and polyamide, which is applied in the field of materials and can solve the problems of low flame retardant efficiency of magnesium hydroxide, very large addition amount, and impact on mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

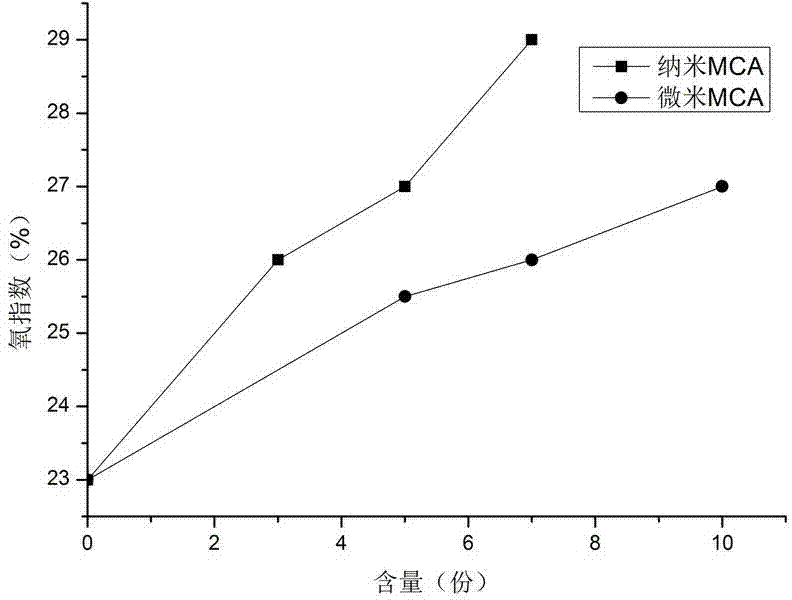

[0014] First, weigh 100 parts by weight of polyamide-6 raw materials, 5 parts by weight of nano MCA halogen-free flame retardant, and 0.1 parts by weight of antioxidants, and mix these materials uniformly. Then preheat the twin-screw extruder to 240°C, add the uniformly mixed raw materials into the twin-screw extruder, control the screw speed to 200r / min, and pellet the product to obtain halogen-free nano flame-retardant polyamide-6 .

Embodiment 2

[0016] First, weigh 100 parts by weight of polyamide-6 raw materials, 7 parts by weight of nano MCA halogen-free flame retardant, and 0.2 parts by weight of antioxidants, and mix these materials uniformly. Then preheat the twin-screw extruder to 230°C, add the uniformly mixed raw materials into the twin-screw extruder, control the screw speed to 130r / min, and pellet the product to obtain halogen-free nano flame-retardant polyamide-6 .

Embodiment 3

[0018] First, weigh 100 parts by weight of polyamide-6 raw materials, 10 parts by weight of nano MCA halogen-free flame retardant, and 0.5 parts by weight of antioxidants, and mix these materials uniformly. Then preheat the twin-screw extruder to 220°C, add the uniformly mixed raw materials into the twin-screw extruder, control the screw speed to 250r / min, and pellet the product to obtain halogen-free nano flame-retardant polyamide-6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com