Preparation method of rubber or resin light stabilizer

A light stabilizer and rubber resin technology, which is applied in the field of chemical stabilizer preparation, can solve problems such as cracking, stickiness, physical and mechanical properties, and reduced chemical properties, and achieve improved light stability, expanded application range, and good anti-aging effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments;

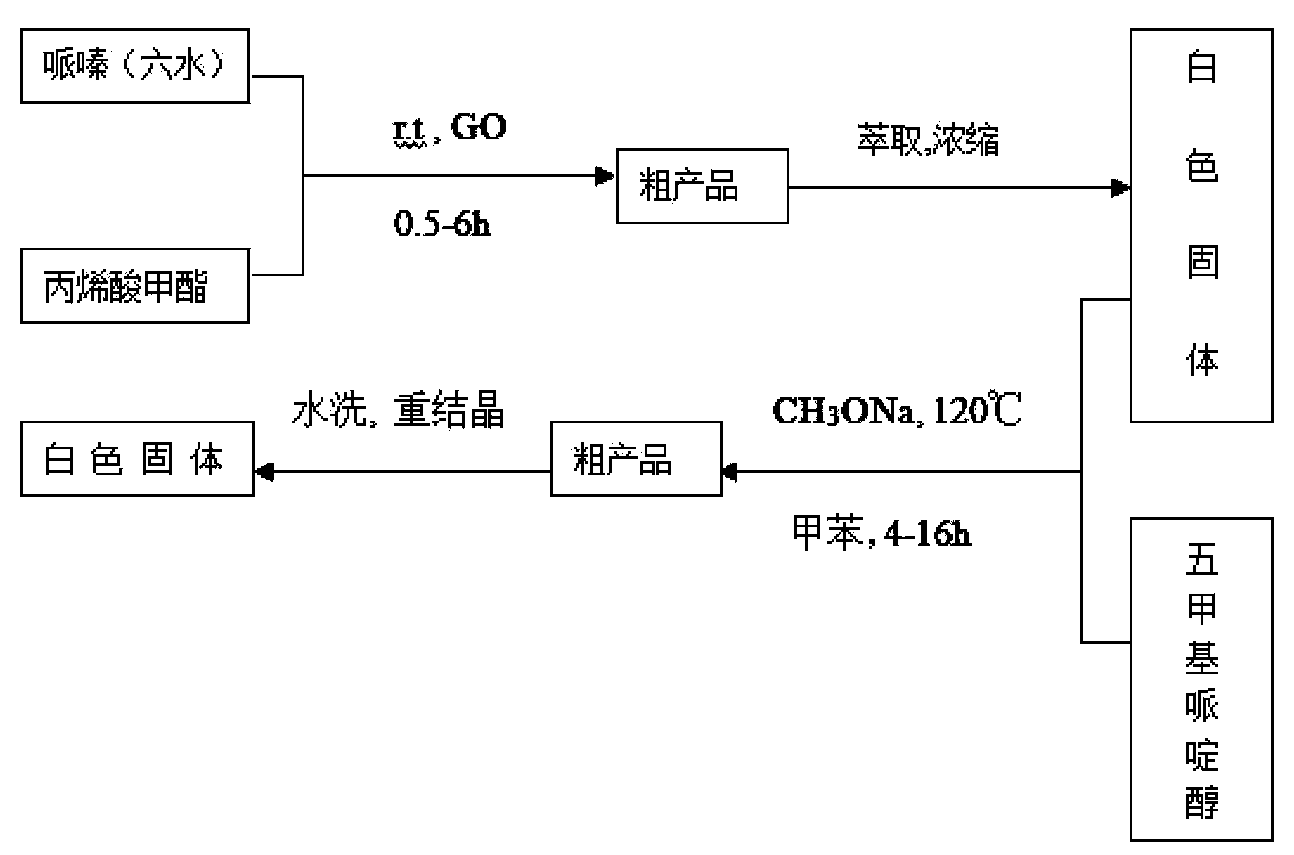

[0013] A method for preparing a new type of rubber or resin light stabilizer, which can be combined with figure 1 , First is the preparation of piperazine-1,4-methyl malonate. The specific process is: add piperazine hexahydrate, methyl acrylate, and graphene oxide aqueous solution to a three-necked flask and stir vigorously at room temperature. The amount is n( Piperazine hexahydrate): n (methyl acrylate)=1:2.0 to 1:9.0. The reaction process was monitored by thin-layer chromatography silica gel plate TLC (methanol: ethyl acetate, v / v=3.0:1~8.0:1), the reaction was stopped after 0.5-6h reaction, and ethyl acetate was used as the extractant to extract the reaction. The mixture, the combined organic phases are collected, dried with anhydrous sodium sulfate, and the organic solvent is removed by rotary evaporation to obtain a white solid, which is the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com