Vacuum glass air-exhaust port sealing structure and manufacturing method thereof

A technology of vacuum glass and sealing structure, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve problems such as low production efficiency, low speed, and difficulty in airtight welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

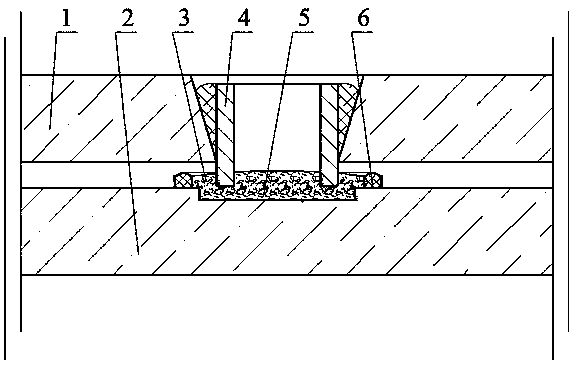

[0073] Example 1: see figure 1 The vacuum glass is composed of upper glass 1 and lower glass 2. A V-shaped through hole is drilled on the upper glass 1 to form an air extraction port, and a metal round tube 4 is inserted into the air extraction port. The top of the tube 4 is lower than the upper glass 1 The upper surface of the circular tube 4 is closely matched with the lower opening of the air extraction port. A groove is formed between the upper part of the circular tube 4 and the air extraction opening. The bottom of the groove is placed with solder, and the solder is glass solder or metal paste. When the round tube 4 and the upper glass 1 are welded together; on the upper surface of the lower glass 2, the glass paste or metal paste is printed into a sealing ring 6 concentric with the suction port by mechanical coating or printing technology, and is sealed The ring 6 is machined with a pit 5 concentric with the suction port. The lower end of the round tube 4 of the upper gla...

Embodiment 2

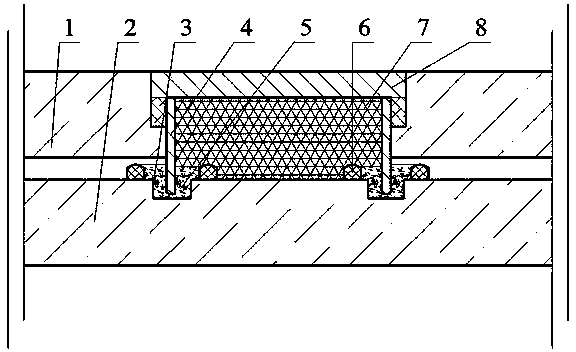

[0074] Example 2: see figure 2 , Basically the same as embodiment 1, the difference is that the suction port is composed of two large upper and lower circular holes, the circular tube 4 is closely matched with the small circular hole, the circular tube 4 is changed to a glass tube, and the metal slurry The material is sintered at the lower end of the round tube 4, and tempered glass ink is placed in the groove, and the upper glass 1 is welded with the round tube 4 when it is tempered; the upper surface of the lower glass 2 is bonded with glass solder or metal paste Two metal rings or glass rings 6, when a metal ring is used, a metal with a coefficient of thermal expansion similar to that of glass, such as Kovar alloy, is preferred. When a glass ring is used, a metal paste is preferably applied; a recess is made in the two sealing rings 6. Groove 5, the inner surface of groove 5 is preferably painted with metal paste to strengthen the sealing effect; the lower end of the round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com