Microwave-heated planar vacuum glass edge-sealed and port-sealed by using sealing strips, and preparation method thereof

A technology of vacuum glass and microwave heating, which is applied in glass manufacturing equipment, glass production, glass molding, etc. It can solve the problems of inability to make toughened vacuum glass, weaken the airtightness of solder performance, and ionize ignition of rare gas to achieve high Bonding strength, reducing sintering temperature or welding temperature, beneficial to welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

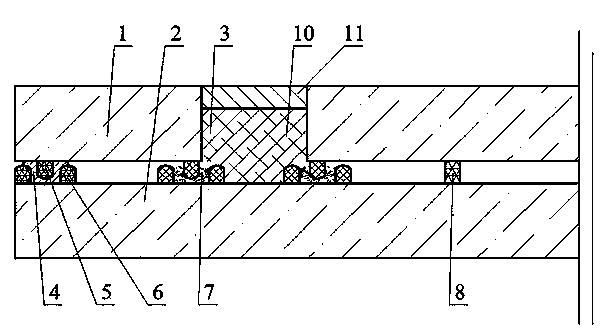

[0042] Embodiment: Referring to the accompanying drawings, the flat vacuum glass is composed of an upper glass 1 and a lower glass 2. The two pieces of glass are tempered glass or semi-tempered glass, and one of them is a low-emissivity glass. The manufacturing method is as follows: Cut a piece of flat glass and a piece of low-emissivity glass according to the shape and size of the required size, remove the film on the welding part of the low-emissivity glass, drill a through hole at the corner of the upper glass 1 as the air outlet 3, and grind the upper and lower glass Edge, chamfering and cleaning, drying, use silk screen printing technology to print the sealing strip on the peripheral welding place of the upper and lower glass and the periphery and corresponding position of the air inlet 3 and print the support 8 on one of the glass at the same time; The piece of glass is sent into the tempering furnace for air-cooling and tempering to obtain tempered or semi-tempered glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com