Method for inhibiting activated sludge bulking of SBR pool

A technology of activated sludge and its application method, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of reduced treatment efficiency, inconvenient maintenance and management, and high cost, and achieve resistance The impact of water volume and organic matter, the effect of stable operation, and the effect of good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

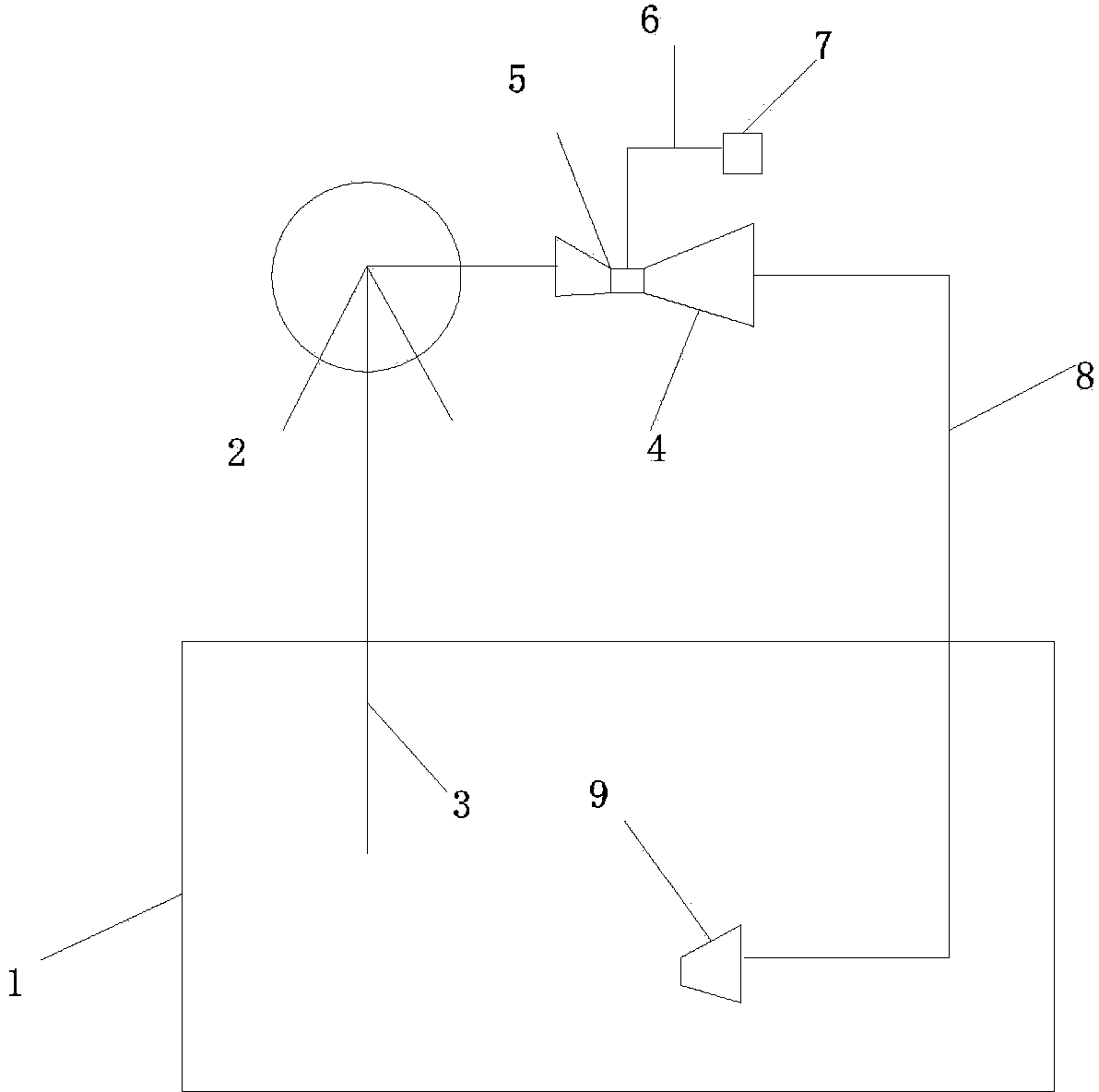

[0024] In the SBR tank of a sewage treatment plant in a certain city, it was detected that the sludge volume index was 500, and the sludge sedimentation ratio was 50%, which was much higher than 30%. Therefore, there was no good impact resistance, so in the SBR tank (1) A platform is built next to it, and a self-priming pump (2) is placed. One end of the self-priming pump (2) has a pipeline (3) extending into the SBR sludge tank (1), and the other end is connected to the Venturi ejector (4); The jet (4) throat (5) is connected to an air duct (6), the air duct (6) is directly connected to the ozone generator (7), and the outlet of the Venturi jet (4) is connected to the nozzle (9); Start the ozone generator (7), and open the self-priming pump (2) at the same time. Under the action of the self-priming pump (2), the activated sludge and sewage in the SBR enter the Venturi jet (4) at the same time, mix with ozone, and pass through The pipeline (8) is ejected from the nozzle (9). A...

example 2

[0026] In the SBR tank of a sewage treatment plant in a certain city, it was detected that the sludge volume index was 560, and the sludge sedimentation ratio was 58%, which was much higher than 30%. Therefore, there was no good impact resistance, so in the SBR tank (1) A platform is built next to it, and a self-priming pump (2) is placed. One end of the self-priming pump (2) has a pipeline (3) extending into the SBR sludge tank (1), and the other end is connected to the Venturi ejector (4); The jet (4) throat (5) is connected to an air duct (6), the air duct (6) is directly connected to the ozone generator (7), and the outlet of the Venturi jet (4) is connected to the nozzle (9); Start the ozone generator (7), and open the self-priming pump (2) at the same time. Under the action of the self-priming pump (2), the activated sludge and sewage in the SBR enter the Venturi jet (4) at the same time, mix with ozone, and pass through The pipe (8) is ejected from the nozzle (9). After...

example 3

[0028] In the SBR tank of a sewage treatment plant in a certain city, the sludge volume index was detected to be 710. The sludge in the wastewater has expanded, and the sludge settlement ratio is 50%, which is much higher than 65%. Therefore, it does not have good impact resistance. So a platform is built next to the SBR pool (1), and a self-priming pump (2) is placed. One end of the self-priming pump (2) (3) extends into the SBR sludge pool (1), and the other end is connected to the Venturi jet. connected to the ozone generator (4); the Venturi jet (4) throat (5) is connected to an air duct (6), and the air duct (6) is directly connected to the ozone generator (7), and the outlet of the Venturi jet (4) Connect with the nozzle (9); start the ozone generator (7), and open the self-priming pump (2) at the same time, under the action of the self-priming pump (2), the activated sludge and sewage in the SBR enter the Venturi jet (4 ), mixed with ozone, through the pipeline (8), spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com