Rolling tension control method of double-rack four-roller mill

A four-high mill, rolling tension technology, applied in tension/pressure control, metal rolling, etc., can solve problems such as unstable product quality and rolling efficiency not being the highest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

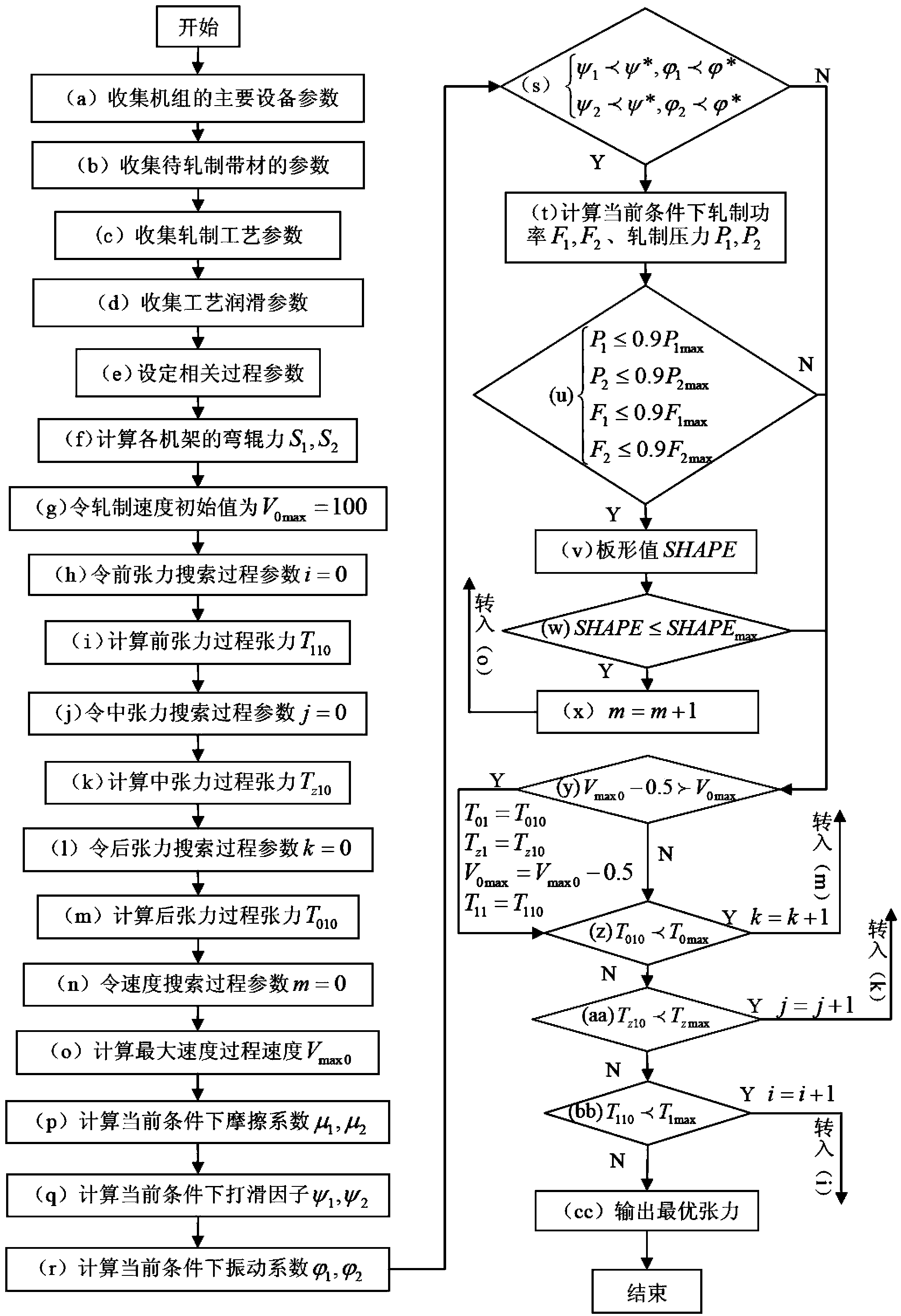

[0050] In view of the fact that the setting of the tension system in the high-grade automobile plate rolling process of the previous double-stand four-roll mill is mainly based on tables and field experience, which cannot guarantee production efficiency and defect prevention at the same time, the present invention provides a double-stand four-roll The tension optimization setting technology of the high-grade automobile plate cold rolling process of the rolling mill, through which the following three functions can be realized: (1) to maximize the rolling speed and ensure the rolling efficiency; (2) to ensure the shape quality of the strip ; (3) Avoid the occurrence of defects such as slipping and vibration to the greatest extent.

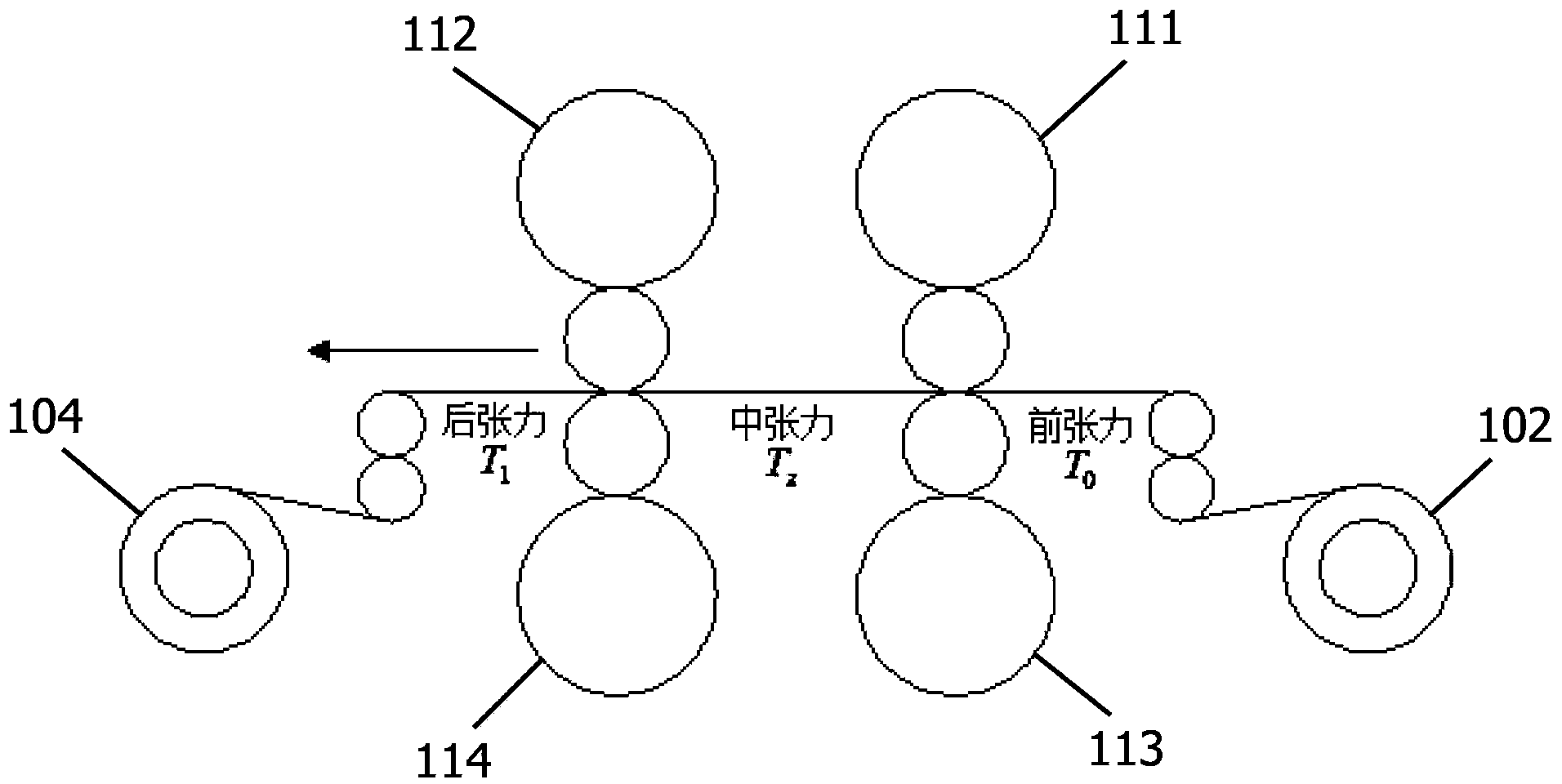

[0051] figure 1 A schematic structural diagram of a two-stand four-high rolling mill is disclosed. Two-stand four-high rolling mill is the most commonly used equipment in the process of processing high-grade automotive sheet from strip. figure 1 A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com