Rubber material forming die for low-compression EPDM sealing ring and application and processing method thereof

A processing method and sealing ring technology, which is applied in the field of rubber seal processing, can solve the problems that special-shaped rubber rings are difficult to take into account high temperature resistance, high heat cooling liquid immersion resistance, low compression permanent deformation shape quality, etc., to achieve both shape quality and performance requirements , Reduce product scrap rate, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 2 As shown, the present embodiment provides a rubber forming mouth shape of a low-pressure variable EPDM sealing ring, including a rubber outlet, and the rubber outlet includes four material opening sections connected at one end, and the four material opening sections are respectively the first material opening Section 1, the second mouth section 2, the third mouth section 3 and the fourth mouth section 4.

[0045] In this embodiment, the four feed opening sections are fan-shaped, the centers of rotation coincide, and the circumferential direction is scattered; and the parameters and mutual positions of each feed opening section are limited, that is, the diameter of the first feed opening section 1 is The width of the first feed opening is 101, that is, the chord length of the arc is 10-20 mm; the diameter of the second feed opening section 2 is The second feed opening width 201 is 10-20mm; the diameter of the third feed opening section 3 is The thi...

Embodiment 2

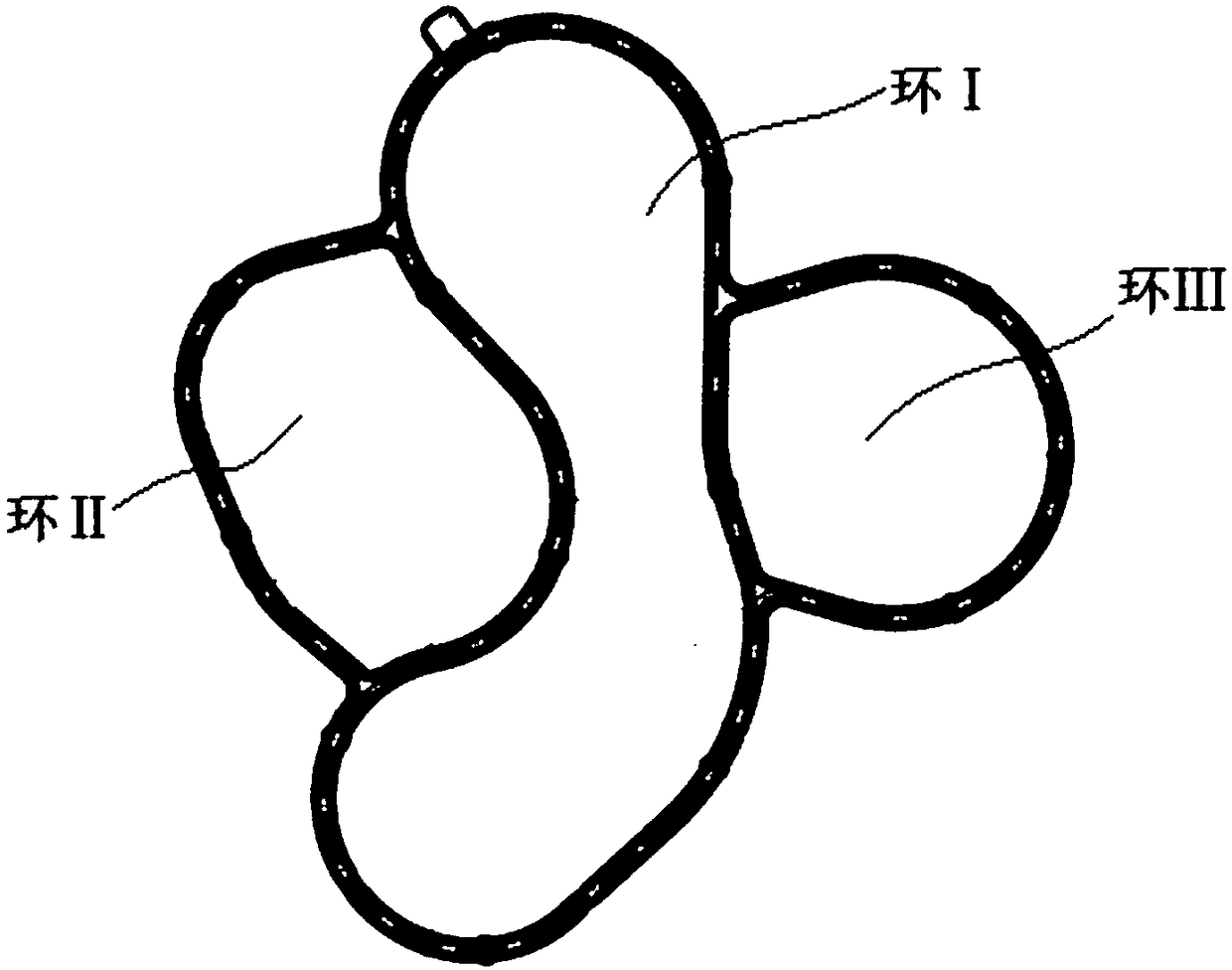

[0049] This embodiment provides a kind of processing method of low-pressure variable EPDM sealing ring, obtains the semi-finished product rubber material of specific shape by adopting the rubber material molding mouth shape of low-pressure variable EPDM sealing ring in embodiment 1, and vulcanization molding produces such as figure 1 Automotive water pump EPDM seal shown.

[0050] In this embodiment, the diameter of the first feed port section 1 in the rubber forming mouth is The first feed opening width 101 is 20mm; the diameter of the second feed opening section 2 is The second feed opening width 201 is 120mm; the diameter of the third feed opening section 3 is The third feed opening width 301 is 20mm; the diameter of the fourth feed opening section 4 is The fourth opening width 401 is 20mm; the angle α between the centerline of the first opening section 1 and the second opening section 2 is 78°; the angle α between the centerline of the first opening section 1 and the...

Embodiment 3

[0065] This embodiment provides a processing method for a low-voltage transformer EPDM sealing ring, which is basically the same as in Embodiment 2, except that:

[0066] In this embodiment, the diameter of the first feed port section 1 in the rubber forming mouth is The first feed opening width 101 is 10mm; the diameter of the second feed opening section 2 is The second feed opening width 201 is 10mm; the diameter of the third feed opening section 3 is The third feed opening width 301 is 10mm; the diameter of the fourth feed opening section 4 is The fourth mouth width 401 is 10mm; the angle α between the centerline of the first mouth section 1 and the second mouth section 2 is 88°; the angle α between the centerline of the first mouth section 1 and the fourth mouth section 4 The included angle β is 135°; the included angle γ between the centerlines of the third feed opening section 3 and the fourth feed opening section 4 is 65°.

[0067] In step one, the EPDM body sizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com