A kind of preparation method and application of food additive

A technology of food additives and compound enzyme preparations, which is applied to the biological extraction of functional active substances of seaweed plants, and the field of preparation of food additives made of seaweed plants as raw materials, to achieve the effect of promoting health and balancing acidity and alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

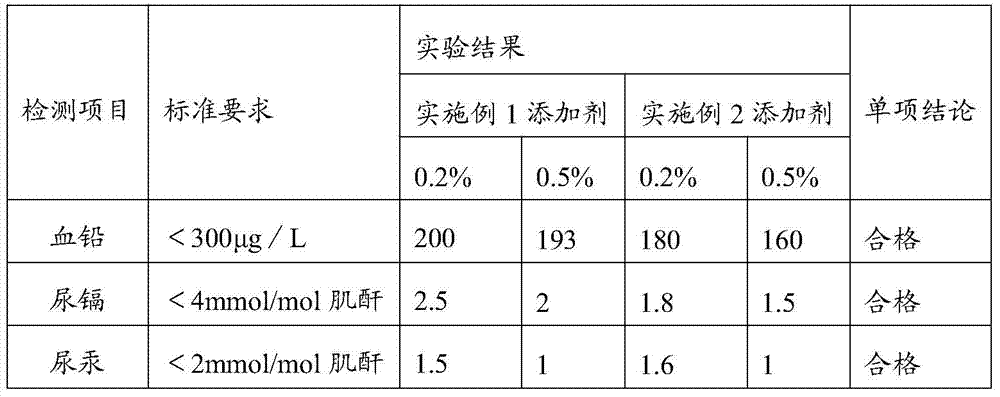

Examples

Embodiment 1

[0030] Preparation of food additives containing red algae extract

[0031] Get 100g of red algae, wash and chop, and prepare according to the following steps:

[0032] (1) Microwave extraction treatment:

[0033] Wash and chop the seaweed, perform microwave extraction with 40 times the weight of water, radiation time 5-10min, microwave power 800-1200W, temperature 35°C, extract 3 times in total, and combine the extracts from 3 times;

[0034] (2) Enzymolysis:

[0035] Concentrate the microwave-treated extract in step (1) under reduced pressure to 1 / 3 of the original volume, and add a compound enzyme preparation composed of cellulase, β-glucanase, and papain at a ratio of parts by weight of 1.2:2.1:1.6 , take it out after 8 hours in a constant temperature water bath at 30°C, put it in -18°C for quick freezing into ice, take it out and let it melt at room temperature, and repeat the quick freezing and thawing cycle three times;

[0036] (3) Bacteria fermentation:

[0037]Ins...

Embodiment 2

[0040] Embodiment 2: Preparation of giant algae extract

[0041] (1) Microwave extraction treatment:

[0042] Get 100g macroalgae, wash and chop, and prepare according to the following steps:

[0043] Wash and chop the macroalgae, extract by microwave with 10 times the weight of 95% ethanol, irradiate for 5-10min, microwave power 800-1200W, temperature 50°C, extract 3 times in total, and combine the extracts from 3 times;

[0044] (2) Enzymolysis:

[0045] Concentrate the microwave-treated extract in step (1) under reduced pressure to 1 / 4 of the original volume, and add a compound enzyme preparation composed of cellulase, β-glucanase, and papain at a ratio of parts by weight of 3.6:5.2:4.5 , take it out after 8 hours in a constant temperature water bath at 30°C, put it in -18°C for quick freezing into ice, take it out and let it melt at room temperature, and repeat the quick freezing and thawing cycle three times;

[0046] (4) Bacteria fermentation:

[0047] Into the enzym...

Embodiment 3

[0052] Embodiment 3: Effect test of activated water

[0053] Group A: Take 10mL of untreated ordinary tap water, filter it after 10min, centrifuge, take the supernatant to test the water molecules 17 O NMR FWHM (NMRFWHM).

[0054] Group B: Take 0.001mL of the food additive of Example 1 and add it to untreated common 10mL tap water, filter after standing for 12 hours, centrifuge, and take the supernatant to test the water molecules 17 O NMR FWHM (NMRFWHM).

[0055] Group C: Take 0.001mL of the food additive of Example 2 and add it to untreated common 10mL tap water, filter after standing for 12 hours, centrifuge, and take the supernatant to test the water molecules 17 O NMR FWHM (NMRFWHM).

[0056] The test instrument is a Brucker AVANCEIII 400MHz superconducting NMR instrument, and the measurement is carried out according to the JY / T007-1996 superconducting pulse Fourier transform NMR method.

[0057] Test results: The half-peak heights of the three groups of samples are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com